No need to choose just one.

Enjoy multiple benefits with GORE® LOW DRAG Filter Bags for cement plants.

Why choose between low emissions and high productivity? You can have it all.

When filter bags underperform, cement plants are left picking up the costs. But you shouldn’t have to choose between productivity and compliance. With the right filter bags, you can optimize kiln feed rates and maintain reliably low emissions.

What’s standing in the way of optimum baghouse performance?

Around the world, cement producers are dealing with challenges such as emissions levels, frequent bag replacement, and lower kiln feed rate – leaving them struggling to maintain productivity and achieve their sustainability goals.

You don’t want your baghouse to be a bottleneck. That’s why you need to address the following issues:

Achieving optimum baghouse performance with Gore

At Gore, we strive to exceed your expectations of filter bag performance. As a world-leading filter bag manufacturer, we deliver scientifically proven PTFE membrane filter bags that enable you to achieve both your productivity and emissions targets, while also benefiting from long-lasting filter bags that promise the lowest total cost of ownership on the market.

GORE LOW DRAG Filter Bags

GORE LOW DRAG Filter Bags are a step change in industrial dry filtration, promising:

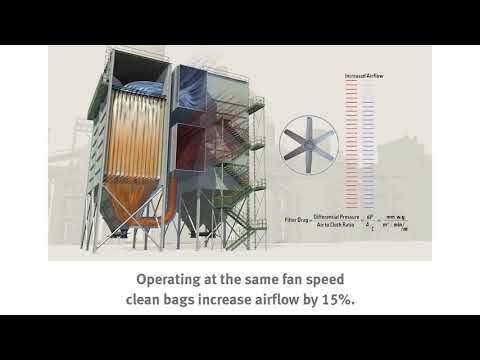

- Increased throughput capability. With increased airflow through the dust filtration bags, production increases are possible without having to increase the size of the baghouse.

- Longer bag life. Alternatively, by operating the same number of bags with the same airflow and the same differential pressure, longer bag life can be achieved.

- Better burning of alternative fuels. Alternative fuels often require greater volumes of airflow for optimised combustion. With our unique PTFE membrane filter bags, you can increase airflow and burn more alternative fuels.

- Fan energy savings. Reduced filter resistance enables the baghouse to operate with lower pressure drop, which means the fan motor can operate at lower rotational speed – cutting both cost and environmental impact.

We have a range of GORE LOW DRAG Filter Bags suitable for every process baghouse.

Click to learn more about:

Get Free ROI Calculation Now

Videos

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.