GORE® Fiber Optic Cables for Defense Air & Land

We’ve packaged higher bandwidth optical fibers in robust, space-saving constructions to accommodate next-gen system requirements. With an exceptional balance of properties, Gore’s Simplex versions offer improved reliability and longevity over alternatives. They’re proven to transmit instant data and video for maximum situational awareness during tactical missions.

Contact Us

+1 800 626 7708

Overview

HIGH-BANDWIDTH SIGNALS WITH IMPRESSIVE ROBUSTNESS

With higher bandwidth requirements rising, fiber optics in military applications must transfer loads of data and video reliably so personnel can quickly gather Intel, maintain communications and react appropriately. Cables must also be smaller and lighter to fit in space-limited areas of combat aircraft, vehicles and tanks.

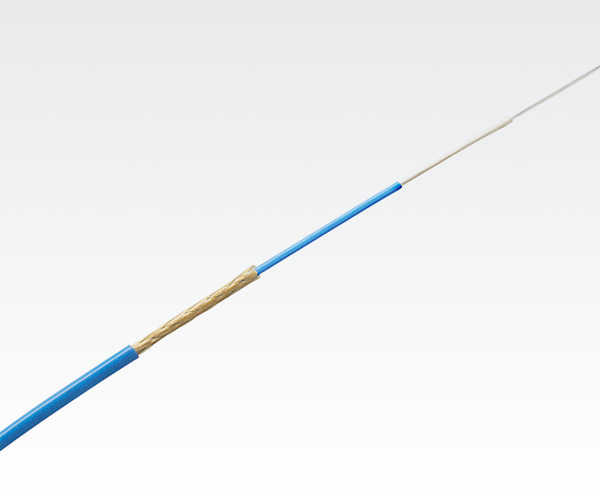

GORE Fiber Optic Cables balance strength, small size, less weight and high flex compared to alternatives. We offer several Simplex versions with single-mode and multi-mode core types up to OM5 to meet many application needs. Delivering strong signals, each version can easily accommodate the military’s bandwidth-intensive requirements supporting next-gen data and video architectures.

Unlike alternatives, we bring a higher level of rugged protection that shields the fiber core from rigorous installation, crushing force, high-intensity vibration, mechanical shock, plus more. All of our versions meet, even exceed, stringent industry standards for fiber optic cable temperature range, durability and optical performance.

Features & Benefits

We construct GORE Fiber Optic Cables with rugged features that safeguard against complex routing and maintenance activities and harsh-environment missions, including:

- Impact- and crush-resistant buffering systems

- chemically inert and temperature-resistant materials

- slender, light cable diameters

For system architects and engineers, our mil-spec fiber optic cable solutions provide a handful of benefits that enhance system performance and longevity, like:

- secure, high-bandwidth data and video transfer with low optical loss up to 100+ Gb/s

- proven resistance to high impact, crushing, abrasion, vibration, shock and more

- proven to exceed new stringent EN4641-301 and JN1177 durability requirements

- easier, faster routing with more flexibility and tighter bend capability

- valued weight and space savings in combat aircraft, vehicles and tanks

- variety of single-mode & multi-mode core types from OM1 to OM5

- compatible with a variety of high-speed connector systems and backshells

1.8 mm Simplex

Gore’s 1.8 mm Simplex version was honored by the Military & Aerospace Electronics Innovators Awards.

Our most popular award-winning version offers many benefits of a fiber optic cable. Built with a remarkable buffering system, our 1.8 mm Simplex is proven to resist high-weight impact, crushing, abrasion and kinking than other fiber optics for aerospace and military applications. It’s also proven to endure high-intensity vibration and mechanical shock in extreme temperatures without optical loss.

These compact, high-density fiber optic cables reliably support next-gen data and video architectures up to 100+ Gb/s without interruption on avionics and vectronics digital networks. This version also exceeds new stringent EN4641-301 and JN1177 standards initially intended for larger, more rugged designs on 10+ Gb/s avionics networks.

1.2 mm Simplex

This military-grade fiber optic cable delivers stable optical performance with low loss for transferring high-bandwidth data and video on avionics and vectronics digital networks. Thanks to its rugged, thin buffering system, our 1.2 mm Simplex combats routing, vibration, shock and tension that can severely impact overall system performance in defense aircraft and armored vehicles.

Smaller and lighter without losing mechanical strength, our standard sealed fiber optic cable minimizes routing and installation complexities in condensed areas of a fiber optic cable communication system.

900 micron (µm)

Like our other Simplex versions, these single and multi-mode fiber optic cable solutions provide high-level crush resistance to protect the delicate fiber core. They deliver quality signals with minimal loss during complex installation, maintenance and mission scenarios. This version also drastically reduces shrink back and shortens sample termination times.

Our 900 micron fiber optic cable is an excellent choice for inside-the-box devices because they’re slender, flexible and easy to route. For outside-the-box systems that need more durability and high-temperature protection, we offer fiber options packaged with our GORE® Cable Protection Systems.

Applications & Connectors

With proven ruggedness, GORE Fiber Optic Cables prove trustworthy in numerous defense aircraft and vehicle applications. Each version of our Simplex cables can be terminated with a variety of leading military-grade fiber optic connectors and backshells, like ARINC, MIL-STD-38999, and MIL-PRF-29504.

| Applications of Optical Fiber in Defense | 1.8 mm Simplex | 1.2 mm Simplex | 0.9 mm Simplex (900 µm) |

|---|---|---|---|

| Avionics/Vectronics Digital Networks | ✓ | ✓ | |

| Ethernet Backbone | ✓ | ✓ | |

| Flight Management Systems | ✓ | ✓ | |

| HD Streaming Camera Systems | ✓ | ||

| HD Streaming Video Systems | ✓ | ✓ | |

| High Bandwidth in-LRU Data Paths | ✓ | ||

| Inside-the-Box Devices | ✓ | ✓ | |

| Intercom/Radio Systems | ✓ | ✓ | |

| In-Vehicle Networking | ✓ | ||

| Laser Pigtails | ✓ | ||

| Outside-the-Box Systems | ✓ | ||

| Radar Systems | ✓ | ||

| Sensor/Processor Connectivity | ✓ | ||

| Strain-Gauge Systems | ✓ | ||

| Transceivers | ✓ | ✓ | ✓ |

| Weather Radar Systems | ✓ | ✓ |

Technical Specs & Drawings

These values demonstrate the optical, mechanical and environmental performance of GORE Fiber Optic Cables for defense air and land. Download our data sheets in the table below for more cable characteristics, performance data, qualifications and part numbers. You can also fill out a short form for instant access to selected drawings.

| Elec./Mech./ Environ. Property | 1.8 mm Simplex | 1.2 mm Simplexb | 0.9 mm Simplex (900 µm) |

|---|---|---|---|

| Signal Transmission Speed Gb/s | Up to 100+ | Up to 10 | Up to 100 |

| Max Optical Loss dB/km 850 nm 1300 nm 1310 nm | ≤ 3.0a 3.0 | — ≤ 1.5 — | 3.0 — 1.0 |

| Jacket Material | PFA | Extruded FEP | PEEK |

| Jacket Color | Violet or Tan | Blue | Tan |

| Core Type | SM or Multi-Mode, Graded Index | SM or Multi-Mode, Graded Index | SM or Multi-Mode |

| Coating Type | High-Temperature Acrylate | ||

| Buffering System | ePTFE / Crush-Resistant Layer OD: 900 µm (Nominal) | PTFE | Expanded PTFE |

| Temperature Range °C | -65 to +135 | -55 to +125 | -60 to +135 |

| Data Sheet Data Sheet (EN4641 & JN1177) | Data Sheet | Data Sheet | |

a. Based on Gore’s part numbers GSC-13-84943-07 and GSC-13-84943-17.

b. Based on Gore’s part number FON1307.

Get Samples or Buy

Available in several robust Simplex versions, GORE Fiber Optic Cables offer complete reliability in avionics and vectronics for mission readiness, safety and effectiveness. Browse our inventory and order a complimentary sample of selected pre-qualified mil-spec fiber cables to determine if a particular version is compatible with your application.

If you’re ready to order now, reach out to an authorized distributor for in-stock availability. Or, contact us today to discuss your specific needs and requirements with a Gore aerospace and defense representative.

Resources

Catalog: GORE® High Speed Data Cables for Aerospace & Defense

Brochures, Data Sheets, 12.79 MB

Recent News

Press Release

Gore Showcases Latest Lightweight Aerospace & Defense Solutions at Paris International Air Show

Posted June 16, 2025

W. L. Gore & Associates, a global leader providing solution-oriented innovations that include future materials for aerospace, is proud to showcase its latest lightweight innovations at the Paris International Air Show, held from 16 – 22 June at Le Bourget, France.

Visit us at Booth 900 to experience our live demonstrations and discover how GORE® Cables and Materials enhance Army airframe and aviation systems. Reserve time now with a Gore specialist to discuss how we can help deliver solutions that support mission success, survivability and safety.

Press Release

W. L. Gore & Associates Joins Team FLRAA as a Wire and Cable Supplier for the U.S. Army’s Future Long Range Assault Aircraft Program

Posted May 13, 2025

NEWARK, Del./USA — W. L. Gore & Associates, a global leader in aerospace cables and materials, has joined Team FLRAA, bringing its technology to one of the U.S. Army’s most advanced modernization efforts.

Press Release

Bae Systems Honors W. L. Gore & Associates With a ‘partner 2 Win’ Supplier of the Year Award

Posted April 25, 2025

NEWARK, Del./USA — W. L. Gore & Associates today announced it received a Supplier of the Year award from BAE Systems’ Partner 2 Win program. Gore was selected from a pool of suppliers that delivered exceptional performance and contributions to support supply chain success for BAE Systems’ Electronic Systems sector in 2024.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Contact Us

Related Products

Cables & Cable Assemblies

- Shielded Twisted Pair Cables for Defense Air & Land

- CAN Bus Cables for Defense Aircraft

- Ethernet Cables for Defense Air & Land

- Quad Cables for Defense Aircraft

- FireWire® Cables for Defense Aircraft

- Fibre Channel Cables for Defense Aircraft

- USB Cables for Defense Aircraft

- HDMI Cables for Defense Aircraft

- DVI Cables (Digital Only) for Defense Aircraft

- MIL-STD-1760 Assemblies for Defense Aircraft

- Cable Protection Systems for Defense Aircraft

- Abrasion Resistant Cable Jacket for Defense Aircraft

- CAN Bus Cables for Defense Land Systems

- Coiled Cables for Defense Land Systems

- Quad Cables for Defense Land Systems

- USB Cables for Defense Land Systems

- HDMI Cables for Defense Land Systems

- DVI Cables (Digital Only) for Defense Land Systems

- Coaxial Cables for Defense Land Systems

- Tethered Drone Cables for Commercial & Defense

- Cable Protection Systems for Defense Land Systems

- Abrasion Resistant Cable Jacket for Defense Land Systems

Follow GORE® Fiber Optic Cables for Defense Air & Land