GORE® Shielded Twisted Pair Cables for Defense Air & Land

In a low-profile design, these cables meet today’s higher data rate requirements with controlled impedance while saving valuable weight in defense aircraft and vehicles. They’re built with more durability for lifelong performance so troops can focus on the mission instead of dealing with unreliable systems that can risk the mission and their safety.

Contact Us

+1 800 626 7708

Germany

+49 9144 6010

+49 9144 6816 (fax)

UK

+44 1382 56 1511

+44 1382 56 1007 (fax)

Italy

+39 045 6209 209

+39 045 6209 165 (fax)

France

+33 1 5695 6565

+33 1 5695 6401 (fax)

Spain

+34 93 480 6900

+34 93 373 7850 (fax)

Sweden

+46 31 7067800

+46 31 864226 (fax)

China (Beijing)

+86 10 5707 4999

+86 10 5707 4900 (fax)

China (Shanghai)

+86 21 5172 8299

+86 21 6247 9199 (fax)

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Japan

+81 3 6746 2582

+81 3 6746 2571 (fax)

Overview

FAST SPEEDS WITH DURABILITY

During missions, cables must quickly transfer critical information and maintain stable communications on avionics and vectronics. These cables must also balance ruggedness with smaller, lighter designs to fit in space-restricted areas and keep weight down.

During missions, cables must quickly transfer critical information and maintain stable communications on avionics and vectronics. These cables must also balance ruggedness with smaller, lighter designs to fit in space-restricted areas and keep weight down.

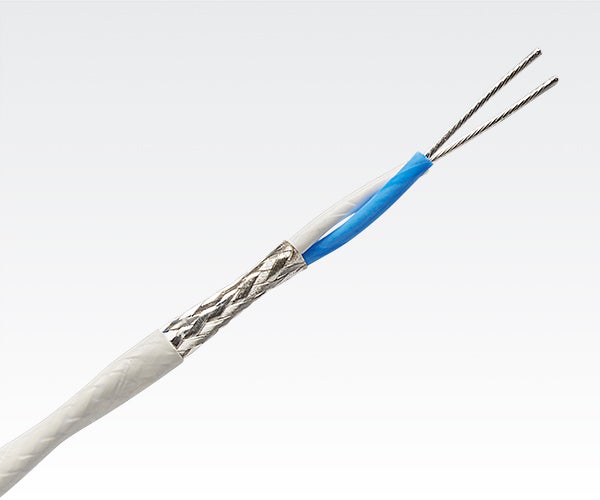

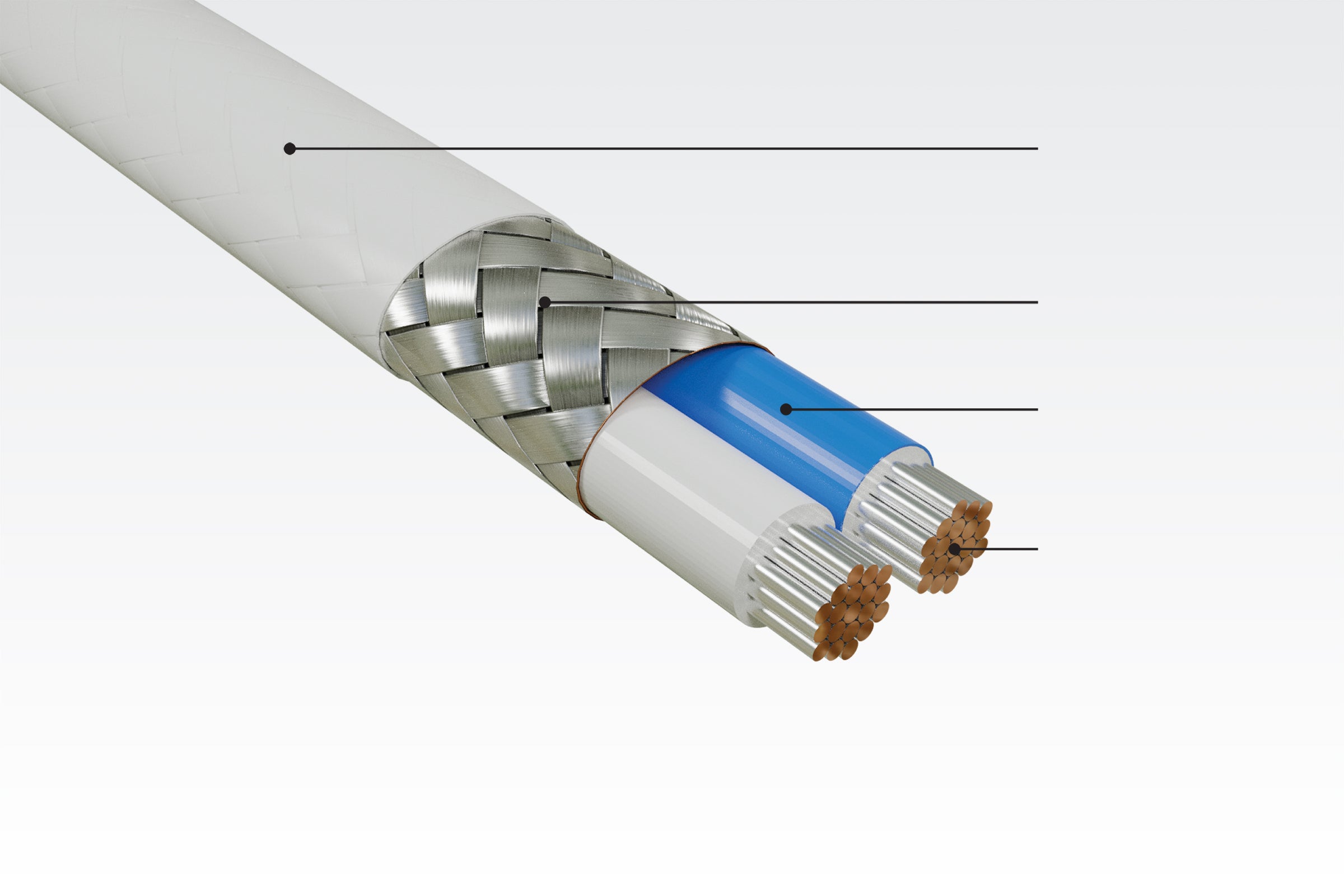

Inside GORE Shielded Twisted Pair Cables, we use low-voltage differential signal (LVDS) technology to transfer data and video at speeds up to 1 GHz with controlled impedance. Regardless of the mission conditions, armed forces can count on their reliable performance in aircraft and vehicles. That’s because the combination of durable materials in our cable construction tolerates mechanical stresses and environmental factors, like changing climate zones, constant vibration and rigorous routing.

BIG WEIGHT SAVINGS

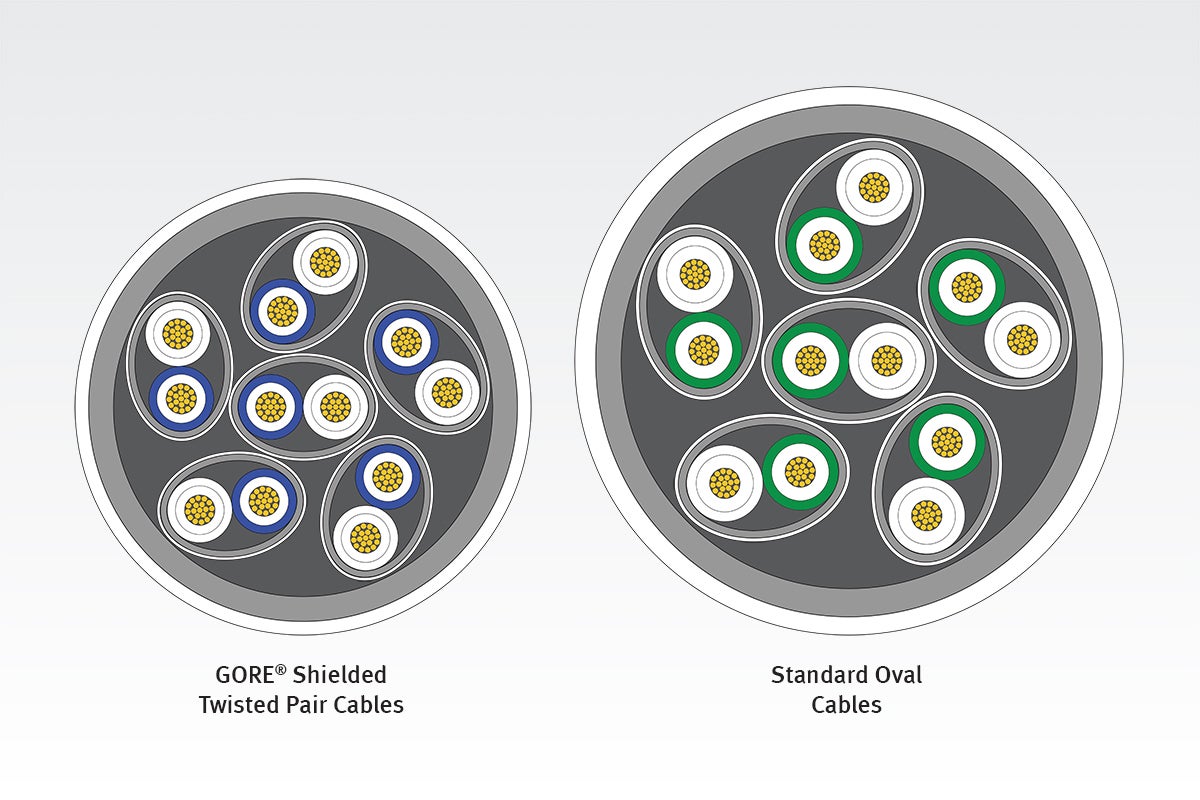

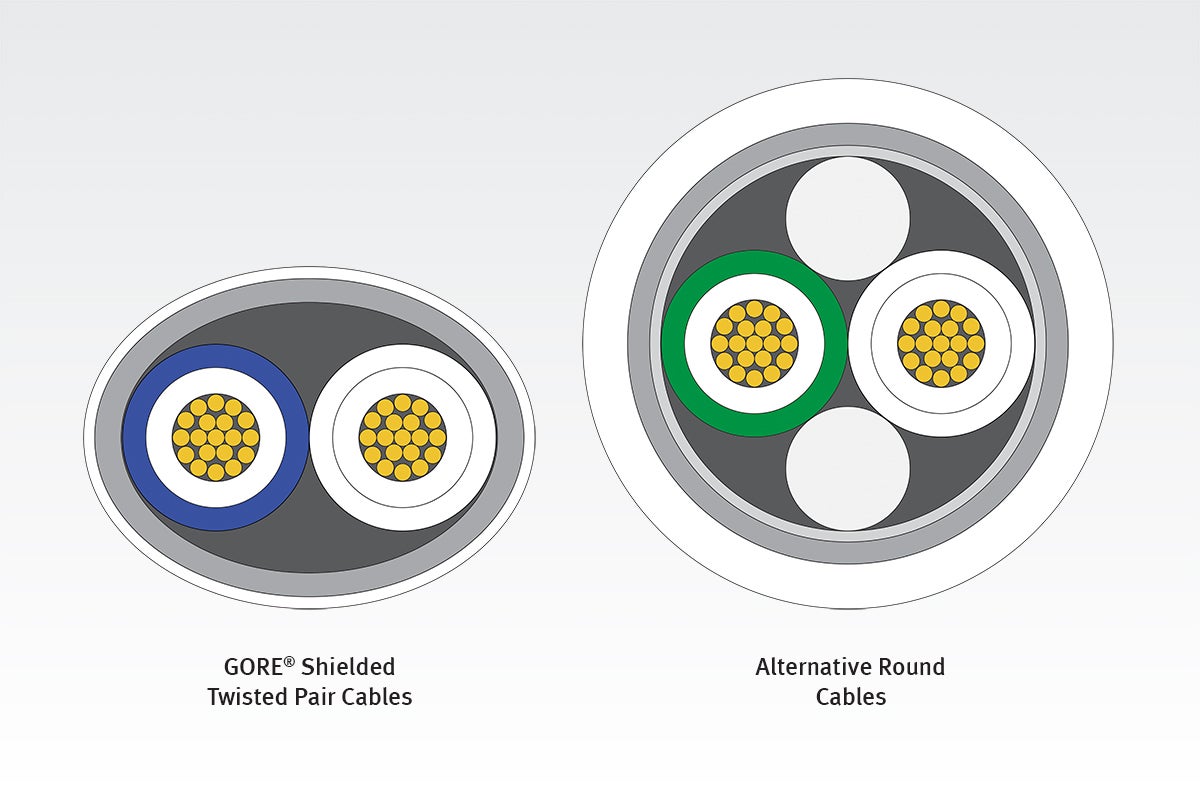

We build our Mil-spec twisted pair cables in a low-profile design that’s 30% smaller, reducing their weight by as much as 50% compared to standard oval cables. If you compare our ePTFE shielded wire design side by side with alternative round designs, you’ll notice that our cable is much smaller. Plus, our cables are more flexible and routable in hard-to-reach places of airframes and vehicle structures.

Low-profile configuration

Smaller diameter

Durable package of GORE Shielded Twisted Pair Cables.

Applications

We thoroughly test and qualify GORE Shielded Twisted Pair Cables to meet stringent STP cable specification standards, like the National Electrical Manufacturers Association (NEMA) and VG95218-31 performance requirements. Their reliable performance is well-suited for wire and cable harness applications, like:

- avionics/vetronics digital networks

- Ethernet backbone

- HD streaming camera/video systems

- high-density connectors

- LVDS devices

- sensor/processor interconnects

- serial buses

Our cables can also be terminated with a variety of leading shielded twisted pair connector systems and backshells, like ARINC and MIL-STD-38999 with differential Twinax sizes 8 and 22D contacts.

Features & Benefits

Unlike standard oval or alternative round versions, GORE Shielded Twisted Pair Cables are engineered with unique features that make them more durable against harsh maintenance and operational environments, including:

- chemically inert, polyimide-free materials

- abrasion- and temperature-resistant materials

- low-profile cable configuration

For system architects and engineers, our twisted pair wire cable offers numerous benefits that ensure lifetime performance in defense aircraft and vehicles, like:

- reliable LVDS technology with controlled impedance at 100 ohms

- dependable twisted pair cable data transfer rate up to 1 GHz

- 30% smaller and 50% lighter than standard oval cables

- higher tolerance against extreme temperatures, cut-through, vibration, more

- improved installation from higher flexibility and tighter bend radius

- compatible with a variety of leading cable connector systems and backshells

Technical Specs & Drawings

These values demonstrate the electrical, mechanical and environmental performance of GORE Shielded Twisted Pair Cables for defense air and land. Download our data sheet for more benefits and characteristics of shielded twisted pair cable part numbers. Also, fill out a short form for instant access to selected drawings.

| Elec./Mech./Environ. Property | Value |

|---|---|

| Signal Transmission Speed GHz | Up to 1 |

| Standard Impedance Ohms | 100 ± 10 |

| Typical Operating Voltage V | <15 |

| Nominal Velocity of Propagation % | 80 |

| Nominal Time Delay ns/m (ns/ft.) | 4.10 (1.25) |

| Capacitance pF/m (pF/ft.) | 42.6 (13.0) |

| Dielectric Withstanding Voltage Vrms Conductor-to-Conductor Conductor-to-Shield | 1500 / 700a 1000 |

| Jacket Material | Engineered Fluoropolymer or PU Halogen-Freea |

| Jacket Color | EF: White (Laser Markable) PU: Blacka |

| Conductor | Silver-Plated Copper or SPC Alloy |

| Conductor Color-Coding | Blue/White |

| Dielectric Material | Expanded PTFE (ePTFE)/PTFE |

| Temperature Range °C | -65 to +200 -46 to +100a |

a. Based on Gore’s part number GSC-03-85203-VG, 22 (19/34) for military vehicle systems.

Get Samples or Buy

Smaller, lighter and stronger than alternatives, GORE Shielded Twisted Pair Cables have been proven trustworthy in transmitting high-speed data and video in avionics and vectronics. Confirm the quality of our cables and their compatibility with your aviation or vehicle application by ordering from our selection of complimentary pre-qualified samples.

You can buy our cables through an authorized distributor if you’re ready now. Or call us today to talk about the uses of shielded twisted pair cable sizes that we offer based on your specific application needs and requirements.

Resources

Catalog: GORE® High Speed Data Cables for Aerospace & Defense

Brochures, Data Sheets, 12.79 MB

View all resources for GORE Shielded Twisted Pair Cables for Defense Air & Land

Recent News

Press Release

Gore Showcases Latest Lightweight Aerospace & Defense Solutions at Paris International Air Show

Posted June 16, 2025

W. L. Gore & Associates, a global leader providing solution-oriented innovations that include future materials for aerospace, is proud to showcase its latest lightweight innovations at the Paris International Air Show, held from 16 – 22 June at Le Bourget, France.

Visit us at Booth 900 to experience our live demonstrations and discover how GORE® Cables and Materials enhance Army airframe and aviation systems. Reserve time now with a Gore specialist to discuss how we can help deliver solutions that support mission success, survivability and safety.

Press Release

W. L. Gore & Associates Joins Team FLRAA as a Wire and Cable Supplier for the U.S. Army’s Future Long Range Assault Aircraft Program

Posted May 13, 2025

NEWARK, Del./USA — W. L. Gore & Associates, a global leader in aerospace cables and materials, has joined Team FLRAA, bringing its technology to one of the U.S. Army’s most advanced modernization efforts.

Press Release

Bae Systems Honors W. L. Gore & Associates With a ‘partner 2 Win’ Supplier of the Year Award

Posted April 25, 2025

NEWARK, Del./USA — W. L. Gore & Associates today announced it received a Supplier of the Year award from BAE Systems’ Partner 2 Win program. Gore was selected from a pool of suppliers that delivered exceptional performance and contributions to support supply chain success for BAE Systems’ Electronic Systems sector in 2024.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Contact Us

Related Products

Cables & Cable Assemblies

- CAN Bus Cables for Defense Aircraft

- Ethernet Cables for Defense Air & Land

- Quad Cables for Defense Aircraft

- FireWire® Cables for Defense Aircraft

- Fibre Channel Cables for Defense Aircraft

- USB Cables for Defense Aircraft

- HDMI Cables for Defense Aircraft

- DVI Cables (Digital Only) for Defense Aircraft

- Fiber Optic Cables for Defense Air & Land

- MIL-STD-1760 Assemblies for Defense Aircraft

- Cable Protection Systems for Defense Aircraft

- Abrasion Resistant Cable Jacket for Defense Aircraft

- CAN Bus Cables for Defense Land Systems

- Coiled Cables for Defense Land Systems

- Quad Cables for Defense Land Systems

- USB Cables for Defense Land Systems

- HDMI Cables for Defense Land Systems

- DVI Cables (Digital Only) for Defense Land Systems

- Coaxial Cables for Defense Land Systems

- Tethered Drone Cables for Commercial & Defense

- Cable Protection Systems for Defense Land Systems

- Abrasion Resistant Cable Jacket for Defense Land Systems

Follow GORE® Shielded Twisted Pair Cables for Defense Air & Land