Overview

Enclosures and containers are vulnerable. Vulnerable to failed seals, condensation and contamination. Vulnerable to leakage and structural failure.

How likely is an enclosure or container to fail? All it takes is a change in internal pressure that stresses seals. Even a change in temperature or altitude could cause a pressure change, or it could happen because the contents of a container outgas or scavenge oxygen. In the case of mobile devices, enclosures could fail if they’re inadequately protected against liquids, dust and other environmental factors. Whatever the cause, the result could damage a product’s performance and integrity, or even lead to an expensive product failure or significant clean-up.

GORE Vents keep the worst from happening. They allow enclosures and containers to breathe, equalizing pressure and reducing condensation while filtering out liquids and other contaminants. The result: greater product performance, increased durability, higher reliability and peace of mind.

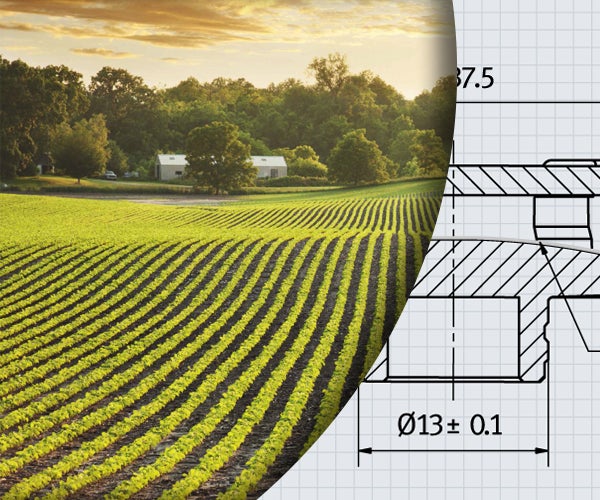

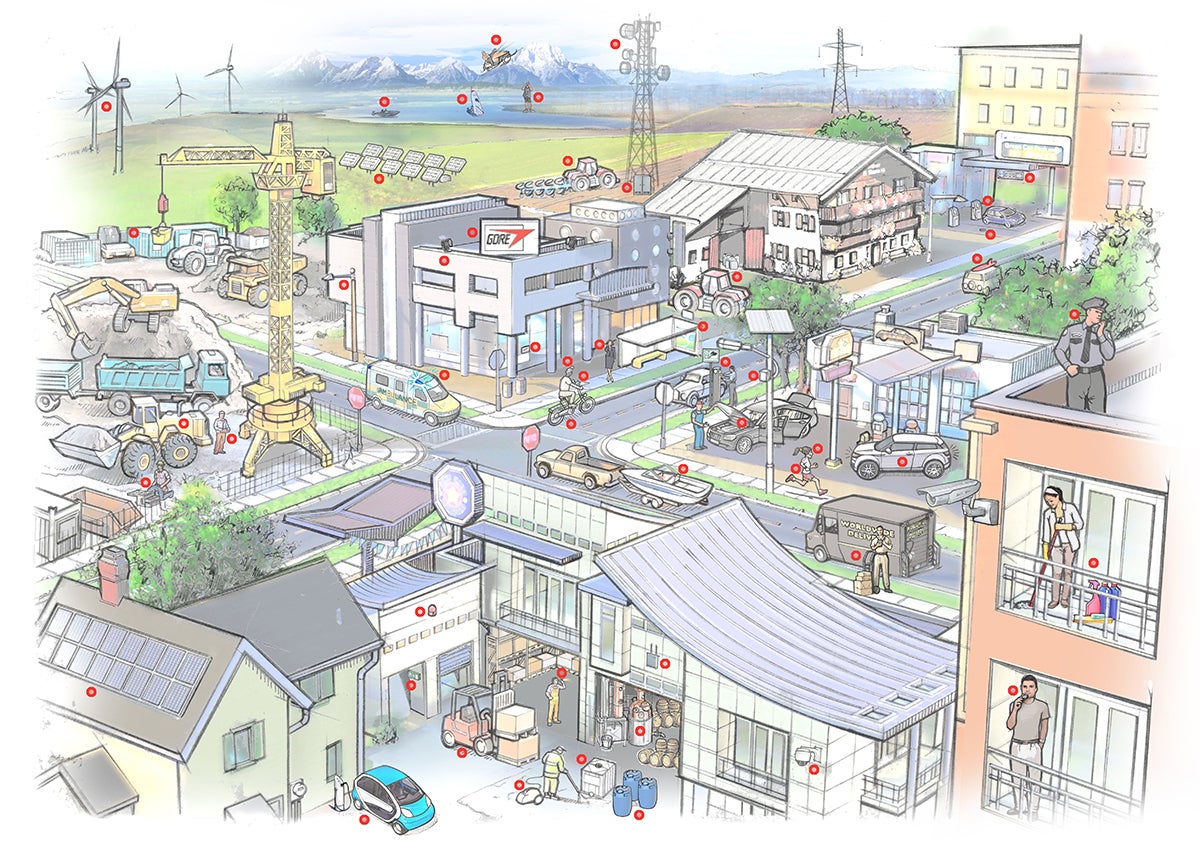

Explore our "App Map" to see dozens of venting applications.

Solutions Across Industries

Gore has paired our technological expertise - particularly in ePTFE, a highly durable and breathable material - with our understanding of venting requirements for automotive components, mobile devices, packaging, outdoor electronics and other devices.

Depending on the application, our vents can:

- equalize internal pressure to prevents leaks

- build a barrier to contaminants

- manage moisture and condensation

- preserve sound quality in acoustic components

- enable devices to survive in rugged environments

- contain challenging or hazardous chemicals in packaging

- enable fluid dispensing from a container, even hot fluids

We design each vent specifically for its application. Once the vent is built, we thoroughly test it in real-world conditions. As a result, vents are designed to perform to specifications - the first time and every time - and deliver outstanding service life.

Vulnerabilities can lead to product failures, customer dissatisfaction and worse. Manufacturers depend on Gore to deliver venting solutions so they, and their products, can breathe easy.

Vents vs. Alternatives

GORE® Vents

Typical Applications

Automotive, Electronics, Packaging, Portable Electronic Devices, Printing

Performance Notes

Optimal combination of performance characteristics, plus long service life for high value-in-use. Can be easily installed.

Hermetic Seals

Typical Applications

Automotive, Semiconductors, Electronics, Optics, Packaging, MEMS, Switches

Performance Notes

Expensive. Difficult to service. Vulnerable to pressure fluctuations due to temperature changes.

Mechanical Valves

Typical Applications

Water and Sewage Processing, Mining, Power Generation, Oil, Gas and Petroleum Processing, Packaging, Food Manufacturing, Chemical and Plastic Manufacturing

Performance Note

Can let devices breathe, but are vulnerable to mechanical failure; often can become stuck. Only work in one direction at a given activation pressure. Can keep fluids in or let them out.

Holes

Typical Applications

Automotive, Electronics, Packaging, Portable Electronic Devices, Printing

Performance Notes

Equalizes pressure but allows full access to water, dust, dirt, debris and insects.

Rubber Tubes with Foam Inserts

Typical Application

Automotive, Electronics

Performance Notes

Inexpensive. Foam insert blocks larger particulates, but ineffective at blocking water and small particulates. Convective flow is difficult to ensure in early design stages.

Cap Vents without a Membrane

Typical Applications

Automotive, Electronics

Performance Notes

Relatively inexpensive. Contaminants and fluid can become trapped in the cap and hinder airflow needed for pressure equalization.

Cap Vents with a Membrane

Typical Applications

Automotive, Electronics

Performance Notes

Blocks contaminants, but can correspondingly reduce airflow and restrict pressure equalization, especially when liquids become trapped in the cap.

Potting Compounds

Typical Applications

Electronics

Performance Notes

Cannot equalize pressures since mechanically stable compound can neither expand nor contract. Can be prone to quality issues due to filling process. Compound may crack and trap water in the cracks. Thermal cycles may damage components.

Mesh

Typical Applications

Portable Electronic Devices

Performance Notes

Inexpensive. Single-layer grid only blocks particles larger than holes in mesh; smaller particles can easily enter and contaminate transducers.

Polyurethane Film

Typical Applications

Portable Electronic Devices

Performance Notes

Inexpensive. Not breathable; cannot equalize pressures or prevent condensation. Fragile; embrittles easily. Vulnerable to UV degradation and thermal shock.

Waterproof Transducers

Typical Applications

Portable Electronic Devices

Performance Notes

Excellent immersion protection. Fails to equalize pressure distortions on front and back side of housing; creates transducer bias, which degrades sound quality and transducer performance.

Robust Seals and Gaskets

Typical Applications

Electronics, Packaging

Performance Notes

Not breathable. Can’t vent device-generated heat, or equalize pressures caused by sudden changes in temperature/altitude. Vulnerable to seal failure and ingress of water/contaminants.

Thick Wall and Rigid Containers

Typical Applications

Packaging

Performance Notes

Increased durability, with increased manufacturing and shipping costs. No pressure equalization, which can cause even “ruggedized” containers to panel, bloat and leak.

Tortuous Paths, Labyrinths and Mazes

Typical Applications

Automotive, Electronics, Packaging, Portable Electronic Devices, Printing

Performance Notes

Relatively inexpensive. Completely open system allows contaminants to enter. Contaminants trapped in pathways block airflow and hinder pressure equalization.

Contact Us

United States

+1 800 523 4673

Australia

+61 2 9473 6800

Brazil

+55 11 5502 7800

China

+86 21 5172 8299

France

+33 1 5695 6565

Germany

+49 89 4612 2211

India

+91 22 6768 7000

Italy

+39 045 6209 240

Japan

+81 3 6746 2572

Korea

+82 2 393 3411

Mexico

+52 81 8288 1281

Scandinavia

+46 31 706 7800

Singapore

+65 6733 2882

Spain

+34 93 480 6900

South America

+55 11 5502 7800

Sweden

+46 31 7067800

Taiwan

+886 2 2173 7799

United Kingdom

+44 1506 460123

Looking for an easier and more convenient way to order GORE® VENTS?

Gore’s redesigned online store will make ordering products more convenient with 24/7 access, ordering tracking, history and more.

Learn more: https://www.gore.com/ventsstoreinfo

Note: The online platform is only available to existing GORE® Vents customers.

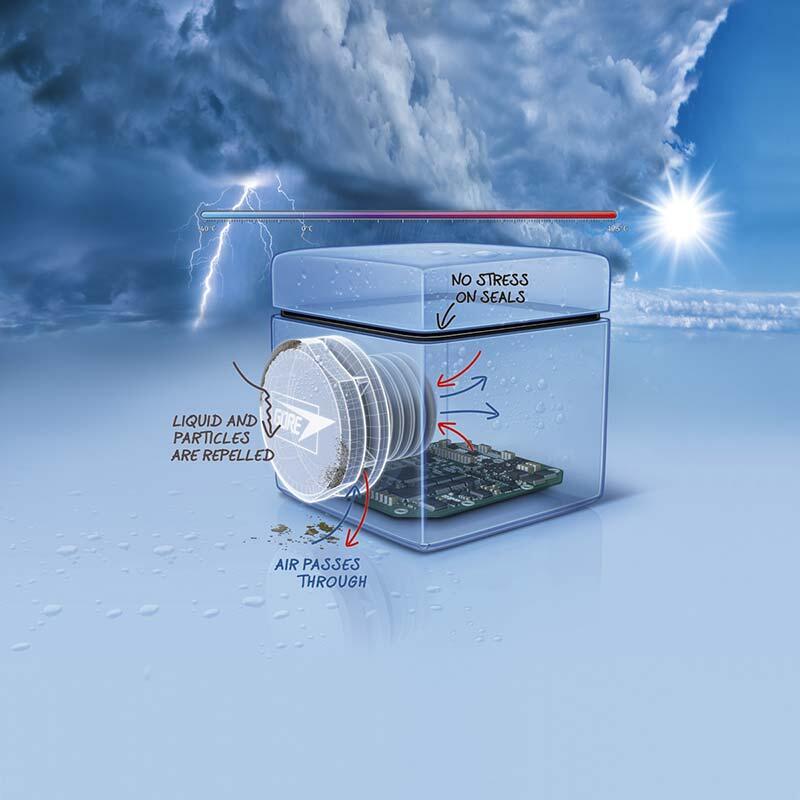

Optimizing Outdoor Electronics with GORE® Protective Vents

A recent field study confirms that GORE® Protective Vents are essential for maintaining the performance and durability of outdoor electronics. These vents ensure rapid pressure equalization, preventing seal damage caused by temperature fluctuations and protecting against water, dust, and other contaminants. An eight-year study in Putzbrunn, Germany, highlights their long-term effectiveness.

Learn more

about these findings in our 2024 white paper.

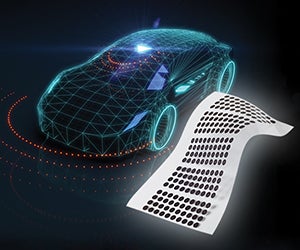

Automotive Vents

Improving reliability while reducing design complexity

NEW GORE AUTOMOTIVE VENT AVS 120:

Enables faster clearing from the same part-size as AVS 9.

Each application has its own set of challenges, such as exposure to temperature changes, environmental conditions like water, dust, dirt and debris or even contact with automotive fluids including urea solutions, car wash fluids, and lubricants. Without the correct venting solution in place, these challenges can impact reliability and durability.

OEMs and Tier-1 suppliers worldwide turn to Gore for advanced automotive venting solutions for gas-powered, hybrid and electric vehicle applications. Our ePTFE vents rapidly equalize pressure variations caused by temperature changes while providing a reliable barrier to particulates, debris, water and automotive fluids. More reliable venting performance can reduce the need for heavier housings, seals and gaskets, so component design is less complex, manufacturing costs and time to market are reduced, and global cross-platform integration is simplified. Reliable acoustic venting can enhance the performance of noise-canceling systems, or driver-assistance systems that monitor important traffic sounds such as emergency vehicle sirens.

At Gore, we provide manufacturers with thorough partnership that includes finding the right solution to their challenges and testing our vents to ensure they meet or exceed industry standards and perform to specifications.

We can rapidly integrate a venting solution into your finished product or work with you to create a custom solution. By pairing our ePTFE venting expertise with unwavering standards for performance, we can help you to maintain the integrity of your products for the long term.

Automotive Vents

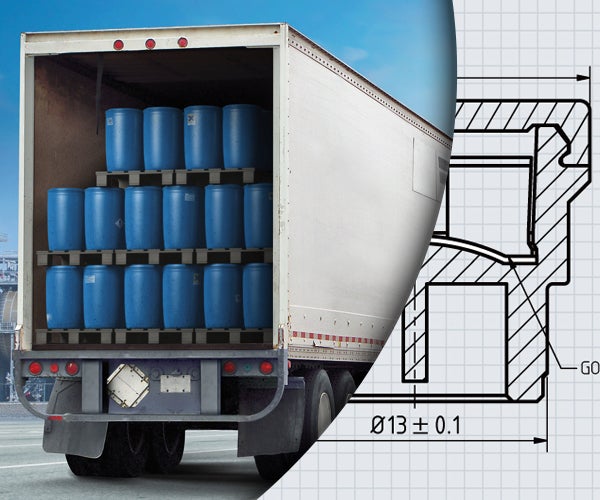

Packaging Vents

Allow Containers to Breathe Without Leaking

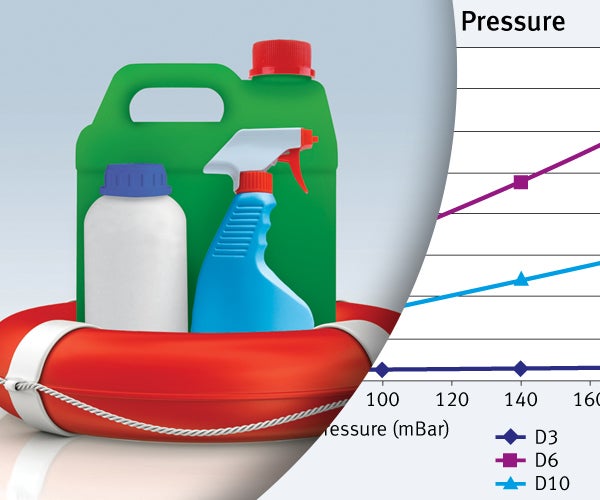

When containers filled with active formulations are not ventilated properly, serious consequence could occur — like bloated or collapsed containers, misaligned pallets, ruined labels and leaks, not to mention costly cleanups and dissatisfied customers.

Risks are even greater when containers are stored, transported or distributed, exposing them to a wide range of altitudes and temperatures that can destabilize pressure and even cause containers to burst. For industrial chemicals and cleaners, agricultural products and household chemicals and cleaners, leaks and ruptures could cause real harm to both users and the environment — unless the containers are properly vented.

Gore’s packaging vents minimize these risks by:

- allowing air and gas molecules to pass through the membrane, continually equalizing pressure so containers won’t bulge or collapse

- maintaining airflow even after contact with high-viscous or low surface-tension liquids

- preventing leakage of dangerous and hazardous liquids

At Gore, we insist on failure-free performance. Our vents are subjected to extensive quality control tests, including thorough camera inspections, to ensure the vent is fit for its use. Additionally, we provide vents that meet the stringent ADR and DOT standards.

Unlike other suppliers, whose vents might clog the membrane or even leak, we provide proven solutions that optimize the safety and compliance of packaging.

The Technology Behind the Vents

What gives our packaging vents their superior performance qualities is expanded polytetrafluoroethylene (ePTFE), the remarkably versatile polymer at the heart of our products.

Gore is the world leader in understanding ePTFE and its capabilities. For each implementation, we use the GORE™ Membrane to engineer an ePTFE membrane structure with a variety of different properties tailored for both the liquid and its container.

Unlike competitors’ membranes, Gore's membranes are designed specifically for packaging venting applications where uncompromising leak protection and pressure equalization are critical. The GORE™ Membrane has excellent roll-off, so it easily “sheds” liquid and allows continuous airflow. Other membranes, while offering adequate initial airflow, experience poor roll-off when exposed to low surface tension liquids. Such liquids clings to and clog those membranes, reducing airflow and potentially causing serious damage.

This membrane has poor roll-off properties, enabling liquid to clog the membrane and reduce airflow.

The Gore membrane has excellent roll-off properties. Liquid easily drains off the membrane, allowing continuous airflow.

The ePTFE membranes in Gore’s packaging vents continually release gases while repelling liquid effectively. The result: containers that more reliably protect their contents during shipment and storage.

Protective Vents for Outdoor Electronics

Improve product integrity and increase product longevity

GORE® Protective Vents for Gearboxes

Reliable Pressure Equalization and Contaminant Protection for Oil-Filled Drivetrains

GORE® Acoustic Vents for Industrial Applications

Protection enabling reliable performance and enhanced sound quality of industrial acoustic devices.

GORE® PROTECTIVE VENTS FOR BESS MODULES

Shield battery energy storage system modules from liquid ingress and corrosion.

Harsh environments can decrease the performance reliability and lifespan of sensitive outdoor electronic equipment. Manufacturers and fabricators know that high-performance venting can be the key to improved profitability and product value.

Gore, the global leader in venting technology and expertise, offers a full range of venting solutions engineered to improve the performance reliability and longevity of outdoor electronics.

In lighting, solar and telecommunications systems, and in heavy machinery, transportation or security/surveillance equipment, GORE Protective Vents:

- rapidly equalize pressure to increase service life, effectively manage condensation and reduce housing design complexity, weight and costs

- reliably protect sensitive electronics against water and other liquids

- effectively block contaminants such as dirt, dust or salts

A choice of adhesive, screw-in and snap-in constructions offer production flexibility, and easy integration into any enclosure. For custom venting solutions, Gore can partner with you on everything from initial design to production-line integration.

Protective Vents for Outdoor Electronics

Resources

GORE® Protective Vents: Positioning Recommendations

Technical Information, 415.54 KB

Portable Electronic Vents

Leading portable electronic device OEMs collaborate with Gore on innovative venting solutions for everything from high-volume consumer products to ruggedized industrial or mil-spec devices. Gore, the global leader in portable electronic venting, offers custom engineering support and standard products to deliver improved acoustic quality and more reliable environmental protection from liquids, dust, and pressure changes.

Let Them Know They Can

New GORE® Acoustic Vent and GORE® Pressure Vent for 10 ATM smartwatches

NEW DESIGN GUIDE

Achieve a better balance of device protection and acoustic performance with GORE® Acoustic Vents.