GORE® Acoustic Vents for Portable Electronics

Trusted by leading OEMs worldwide, our vents provide best-in-class environmental protection while minimizing acoustic loss through advanced technology and design expertise.

Clear Sound, Advanced Particle and Liquid Protection, and Reliable Supply

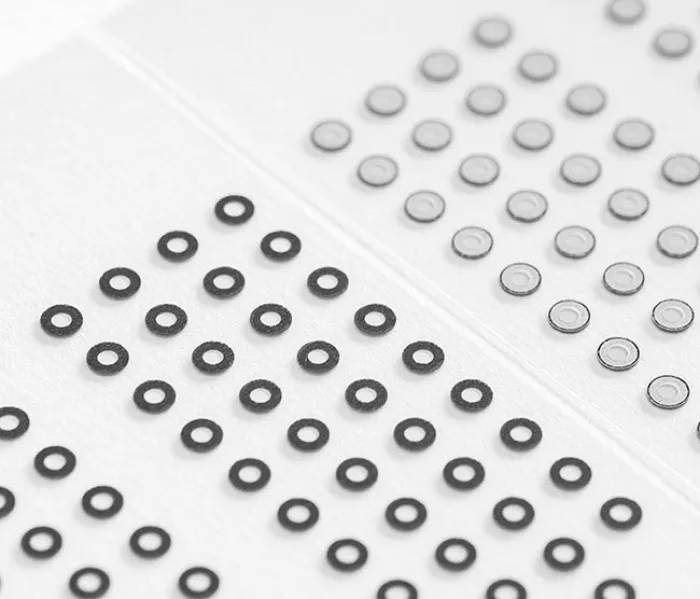

GORE® Acoustic Vents repel dust, liquids, and contaminants while providing consistent high-quality sound. Customizable in size, shape, protection level, mechanical performance, and installation options, they meet diverse acoustic system requirements, from dust applications to deep immersion.

Technical Information

Gore monitors and strives to comply with all regulations applicable to our products.

We have worked with our suppliers to eliminate PFOA from our supply chain. Our products meet EU REACH regulations EU 1907/2006 and EU 2019/2021.

GORE Protective Vents can help your outdoor electronic equipment enclosures meet IP enclosure and vented NEMA enclosure protection standards.

GAW111

GAW112

GAW350

GAW348

GAW333

GAW337

GAW334

GAW342

GAW344

GAW346

Case Studies

Related Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 410 506 7812

Have questions or unique requirements?

Our experts are here to guide you.