GORE® Protective Vents for Solar Energy Systems

Solar system enclosure vents from Gore improve system efficiency and life expectancy while reducing housing design complexity, weight and cost.

Improve Performance, Value and Profit with Our Solar Venting

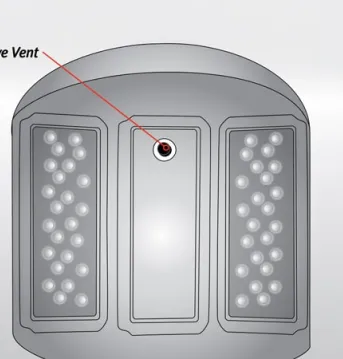

GORE® Protective Vents for solar system housings are engineered to enhance system efficiency, reduce engineering complexity, and lower fabrication costs, delivering long-term reliability and value. Rapidly equalize pressure, block the ingress of contaminates and reduce condensation with screw-in, snap-in or adhesive style vents.

How Protective Vents Work

Watch this simulation to learn how GORE Protective Vents work to equalize pressure and safeguard your electronics.

On-Demand Webinar: Moisture, the Silent Enemy of Electronics

Learn about how to master moisture management in sealed enclosures and protect your battery and electronics.

Technical Information

To effectively equalize pressure equalization and reduce condensation, follow these placement and position recommendations for GORE® Vents.

Gore monitors and strives to comply with all regulations applicable to our products.

We have worked with our suppliers to eliminate PFOA from our supply chain. Our products meet EU REACH regulations EU 1907/2006 and EU 2019/2021.

GORE Protective Vents can help your outdoor electronic equipment enclosures meet IP enclosure and vented NEMA enclosure protection standards.

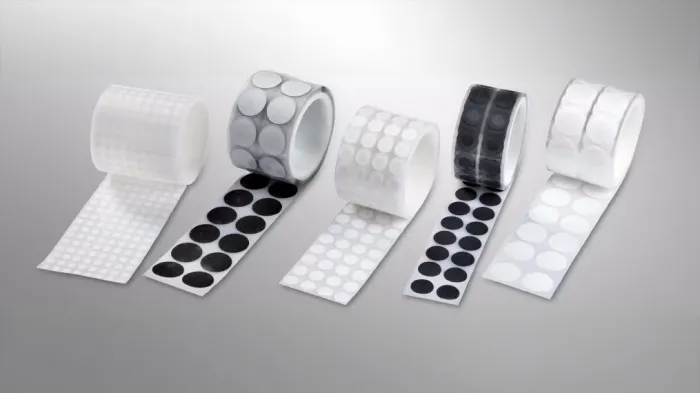

Adhesive Vents

Series VE7

Series VE8

Series VE9

Snap-in Vents

| Product Name | PolyVent Hysi | PolyVent XS |

|---|---|---|

| Product Number | PMF100271 | PMF200125 |

| Product Standard | PolyVent High Airflow | |

| PMF200128 | PMF200484 | PMF200521 |

Screw-in Vents

| Product Name | Thread Size | Product Number |

|---|---|---|

| PolyVent XS | M6x0.75 | PMF100600 |

| PolyVent Standard | M12x1 | PMF100319 (gray) PMF100318 (black) |

| PolyVent Standard | M12x1.5 | PMF100321 (gray) PMF100320 (black) |

| PolyVent High Airflow | M12x1.5 | PMF100586 (gray) PMF100585 (black) |

| PolyVent High Airflow PRO | M12x1.5 | PMF300681 (gray) PMF300680 (black) |

| PolyVent XL | M32x1.5 | PMF200542 |

| PolyVent Stainless Steel | M12x1.5 | PMF200444 |

| PolyVent Ex+ | M12x1.5 | PMF200400 |

Case Studies

Related Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.