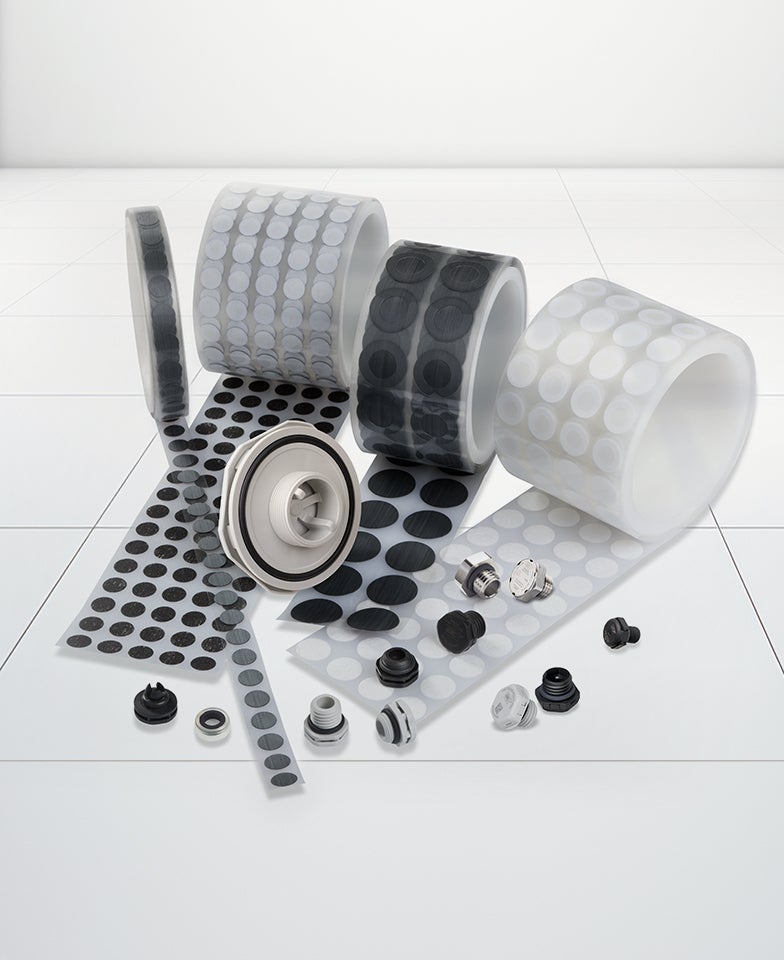

GORE® Vents

GORE® Vents regulate internal pressure in mobile and outdoor electronics enclosures, packaging, and automotive components. They enhance reliability, support long service life and help prevent damage that could lead to component failure.

Protecting Enclosures from Pressure, Contamination and Failure

Pressure imbalances caused by temperature, altitude or outgassing can strain enclosures and housings to the point of failure. If not addressed, dramatic pressure swings can lead to damage from failed seals, leaks, condensation and contamination.

GORE Vents mitigate the risk of damage by allowing enclosures and packaging to breathe. They equalize pressure and reduce condensation while providing an effective barrier to liquids and contaminants like dust, dirt and debris. This ensures superior durability, reliability, and performance.

With GORE Vents, products stay protected—delivering long-term performance and peace of mind.