Overview

Across industries and markets, manufacturers have a need to manage contamination. Telecommunications companies need to protect electronics from liquids and particles; pharmaceutical companies must keep their processes clean; and manufacturers of all kinds must keep mercury and other harmful chemicals contained — not only for their end users, but for our planet itself.

Now, with regulations becoming increasingly stringent, contamination control is an environmental, financial and legal must-have.

Gore’s filtration products help manufacturers separate the bad from the good. From high-volume industrial emissions abatement to processing ultrapure chemicals and water for microelectronics fabrication, our filtration technologies separate impurities and other harmful materials efficiently and reliably.

The materials science behind our filters can even boost productivity while potentially lowering costs. Our filtration products are constructed of advanced materials including expanded PTFE whose structure provides a balance of flow and retention. Because ePTFE is also chemically inert, durable and able to withstand extreme temperatures, our filters are reliable in harsh conditions, over time or when interacting with harmful chemicals. That means less downtime and greater yield.

Gore filtration products are used in a variety of applications, including electronics cabinets in cell phone towers, power generation, pharmaceutical and chemical processing, pulp and paper production, metals processing, and chlor-alkali applications.

Contact Us

North America

+1 800 437 5427

Brazil

+55 11 5502 7800

Germany

+49 89 4612 2211

France

+33 15 695 6565

Italy

+39 045 620 9250

Scandinavia

+46 31 706 7800

Spain

+34 93 480 6900

United Kingdom

+44 1506 46 0123

Particle and Gas Filtration for Industrial Processes & Bag Houses

Gore’s portfolio of catalytic and particle filtration solutions includes filter bags for system optimized emission control and product capture in the chemicals, metals, cement and energy industry. The GORE® Mercury Control System provides both high efficiency and a high capacity for removing elemental and oxidized mercury from flue gas streams and reduces SO2 concentrations.

Particle and Gas Filtration for Industrial Processes & Bag Houses

Filtration Solutions for Life Sciences

Building on our foundation of filtration knowledge and expertise, we continue to develop novel solutions that incorporate our advanced ePTFE membranes to solve the rapidly changing needs of the life science industries and meet stringent quality requirements. Our products are designed to help solve many of the most challenging production issues like enabling improved airflow, increased yield, faster processing time and enhanced process security.

Filtration Solutions for Life Sciences

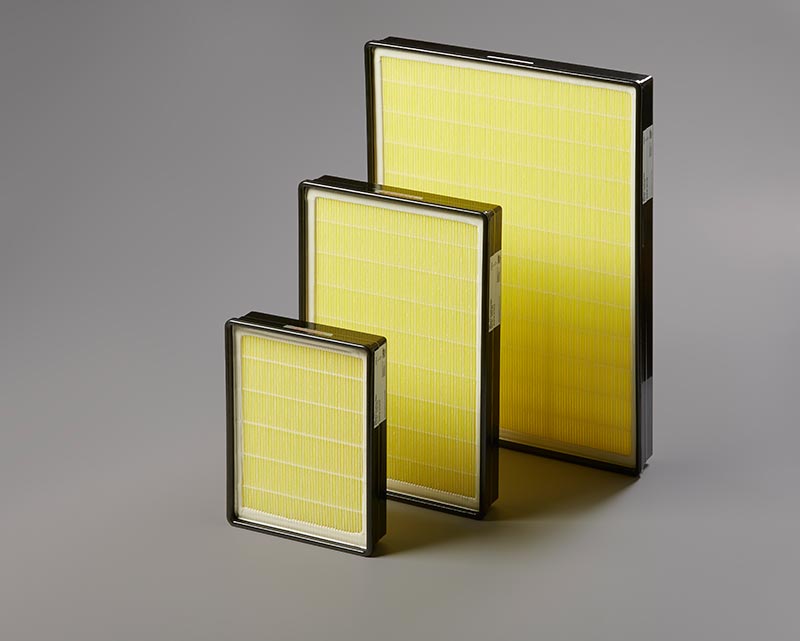

Microfiltration Solutions for Semiconductors and Microelectronics

High-performing products for greater reliability in critical processes.

For manufacturers in the electronics industry, eliminating damaging contaminants is an essential part of the quality process. Gore filtration technology helps manufacturers of semiconductors and microelectronics achieve ever-higher levels of process integrity in critical applications.

Our microfiltration membranes can improve process performance while reducing total process costs for filter makers and chip makers alike.

Microfiltration Solutions for Semiconductors and Microelectronics

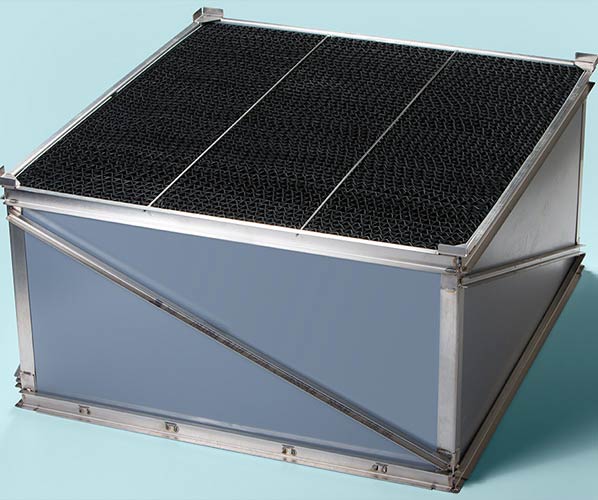

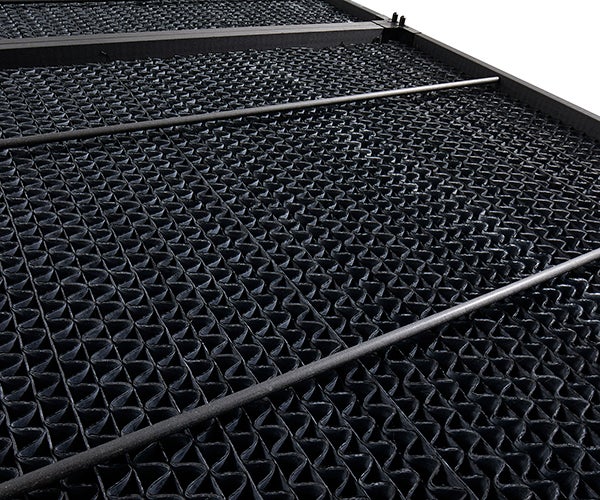

Air Filtration for Gas Turbines and Outdoor Cabinets

Higher performance at lower total cost.

High-performance filtration is critical to the reliability of both gas turbine and outdoor electronic cooling systems. For both applications, Gore’s leading-edge materials technology provides a solution. Our proprietary membrane technology creates a high-efficiency, hydrophobic filter medium that delivers robust, reliable performance in the most challenging environments. Designed to repel the challenges of salt air, heavy pollutants and the most extreme temperatures, these filters simplify and reduce maintenance needs, for more cost-effective system operation.

Air Filtration for Gas Turbines and Outdoor Cabinets

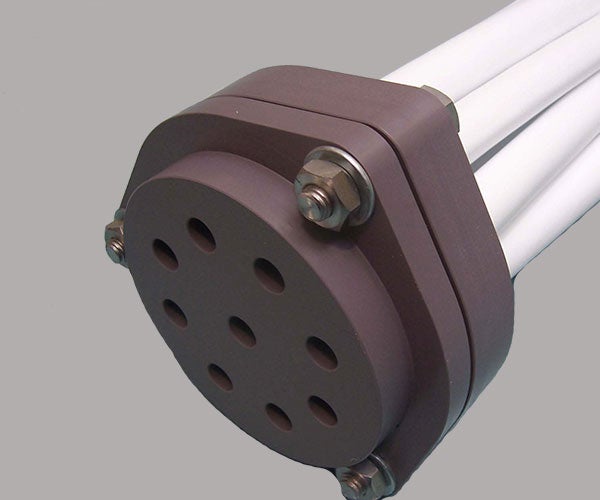

Industrial Fluids Filtration

GORE™ Membrane Filter Sock and Tube assemblies provide excellent filtration efficiency and economical performance in high flow rate and/or high feed solids applications due to a combination of GORE™ membrane's unique properties and extensive application and manufacturing expertise. GORE™ membrane filter socks and GORE® filter tube assemblies are used in Kraft pulp mills, Chlor-Alkali plants and other process or wastewater filtration applications in chemical processing industries.