Dioxin & Furan Catalytic Filter Bags

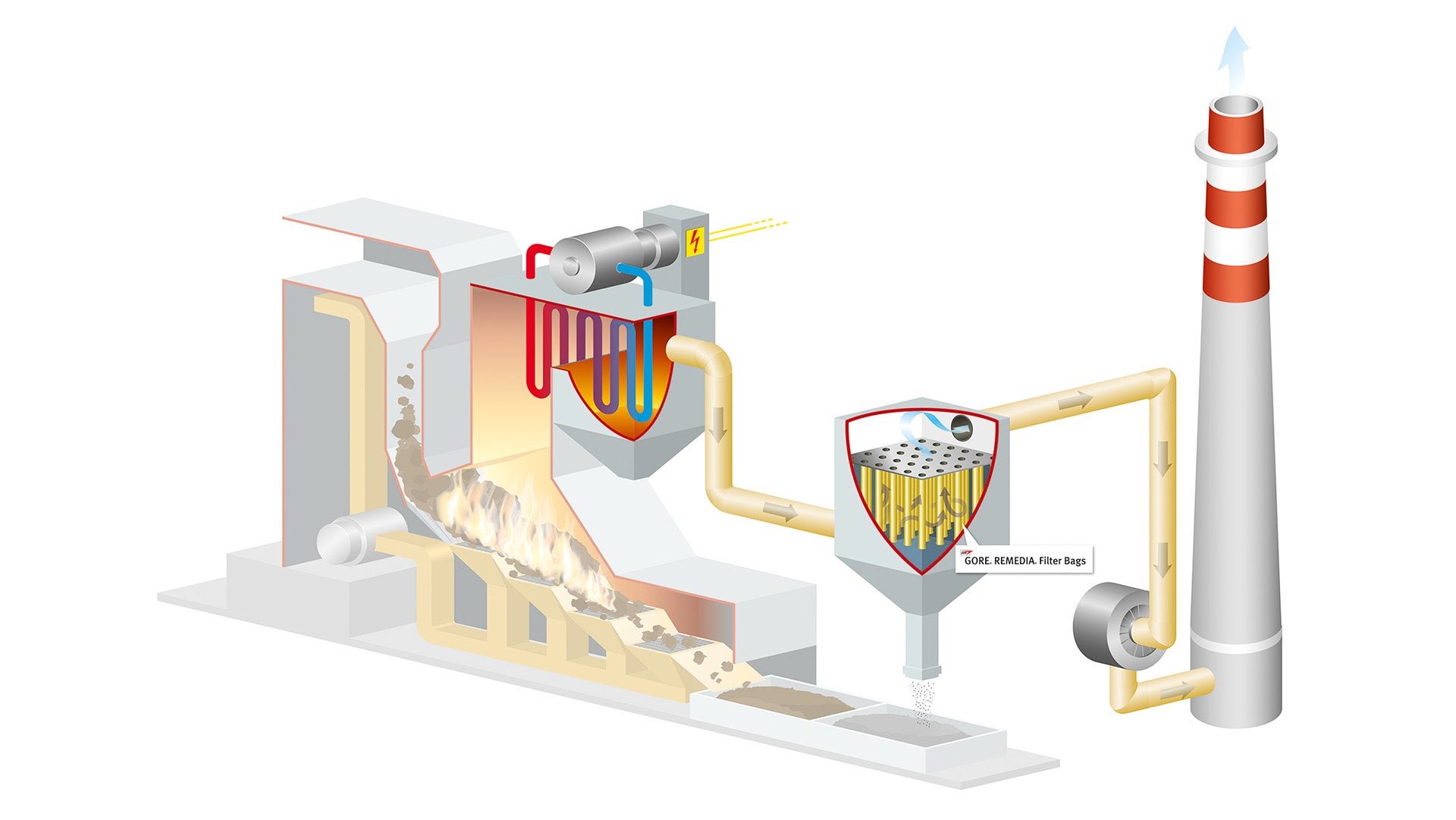

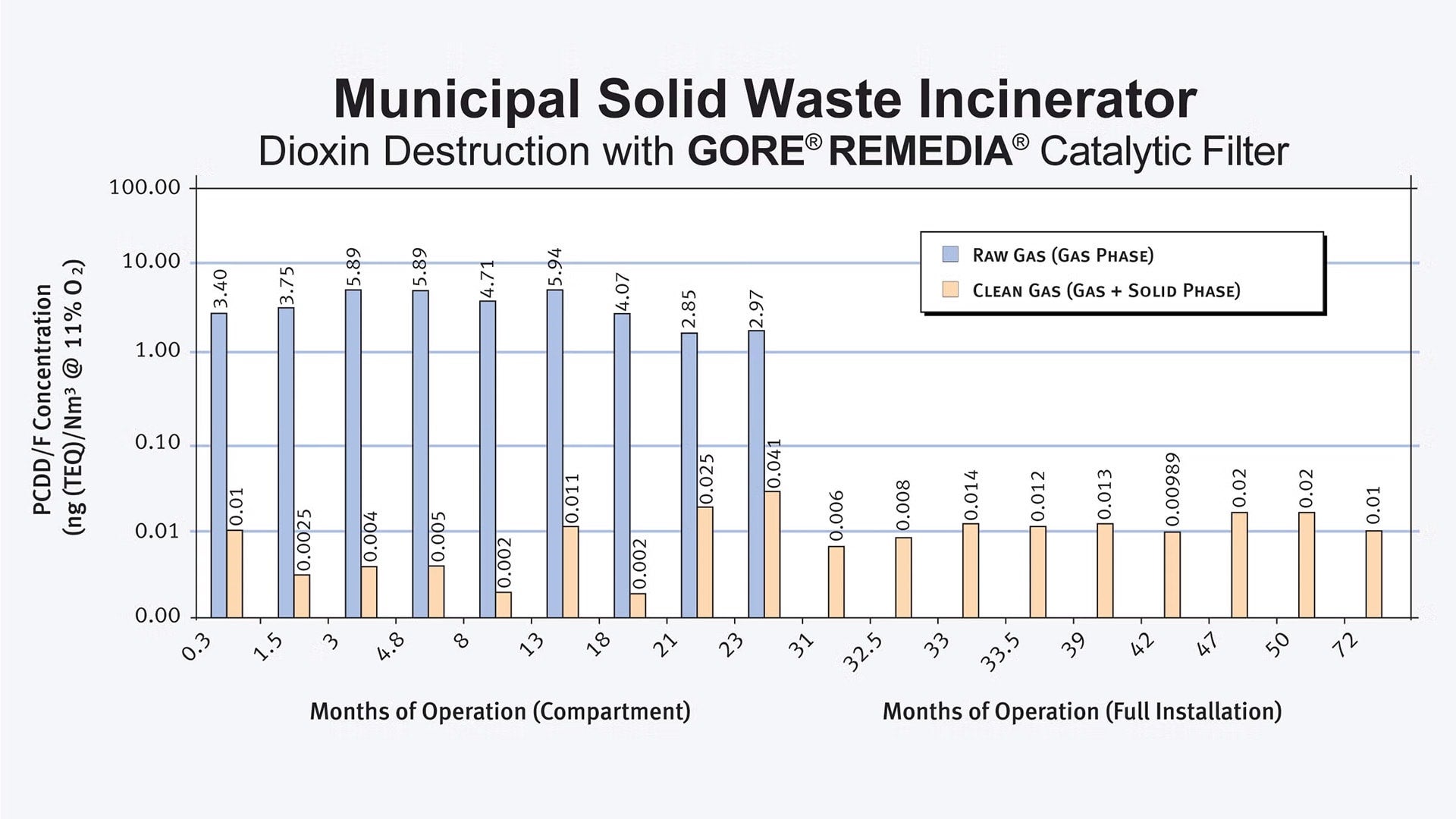

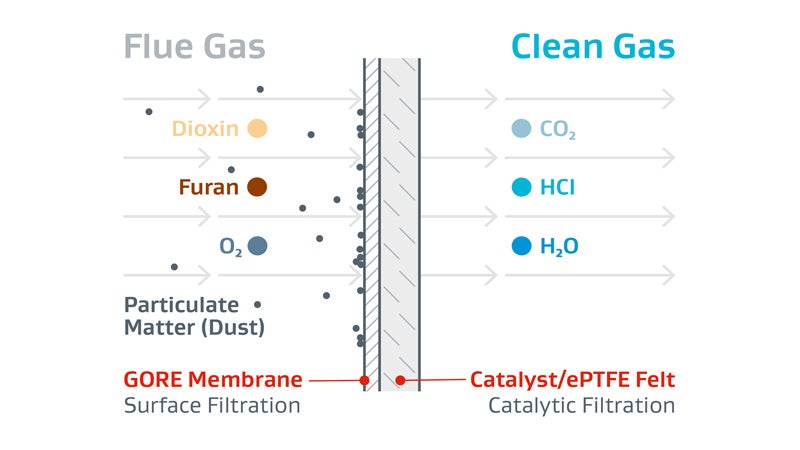

GORE® REMEDIA® Catalytic Filter Bags remove dioxins and furans (<0.1ng/m3), provide dust control and work with existing baghouses in a variety of applications.

Effective, Cost-Efficient Dioxin and Furan Control

GORE® REMEDIA® Filter Bags help you efficiently meet dioxin and furan emissions requirements without the burden of costly new equipment. These bags are specially developed to filter for dioxins and furans from waste incineration, removing it from your gas stream safely and efficiently. The innovative dioxin filter system is safer for the environment and employees, and simpler to use.

Technical Information

GORE REMEDIA CATALYTIC FILTER BAGS*

| |

|---|---|

| Felt content | Staple – Polytetrafluorethylene |

| Felt construction | Scrim – Woven Polytetrafluorethylene |

| Continuous operating temperature | 500ºF / 260ºC (maximum) |

| Maximum surge temperature | 525ºF / 274ºC (maximum) |

| Acid resistance | Excellent |

| Alkali resistance | Excellent |

* All specifications are subject to change without notice

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 231 4364

Have questions or unique requirements?

Our experts are here to guide you.