GORE® MIL-STD-1760 Assemblies for Defense Aircraft

The only sealed hybrid solution proven over time to solve common challenges with pylon installation and critical operations at a cost you can afford. Our certified assemblies with proven high flex life are easy to install and deliver consistent disconnect loads for mission success. They’re flight-proven on many airborne platforms, making them an ideal replacement for standard umbilical assemblies.

Contact Us

+1 800 626 7708

Germany

+49 9144 6010

+49 9144 6816 (fax)

UK

+44 1382 56 1511

+44 1382 56 1007 (fax)

Italy

+39 045 6209 209

+39 045 6209 165 (fax)

France

+33 1 5695 6565

+33 1 5695 6401 (fax)

Spain

+34 93 480 6900

+34 93 373 7850 (fax)

Sweden

+46 31 7067800

+46 31 864226 (fax)

China (Beijing)

+86 10 5707 4999

+86 10 5707 4900 (fax)

China (Shanghai)

+86 21 5172 8299

+86 21 6247 9199 (fax)

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Japan

+81 3 6746 2582

+81 3 6746 2571 (fax)

Overview

PROVEN SAFE OPERATIONS WITH HIGH FLEX LIFE

Successful missions depend on aircraft platforms that use reliable, long-lasting MIL-STD-1760 umbilicals. But, our customers have told us that they often have to replace standard umbilicals using screw-on lanyard, quick-release connectors. Why? Because they’re stiff, hard to handle and don’t withstand pylon installation or operation. Maintenance is time-consuming and costly because it involves removing many aircraft components to replace the damaged umbilicals with new ones.

Gore offers the only sealed hybrid solution proven over time to solve all these problems - an affordable, easy-to-install umbilical with a connector system that doesn't fail when installed or during operation.

GORE MIL-STD-1760 Assemblies with the L3Harris, Field Replacement Connector System™ (FRCS™) are the only solution proven to guarantee safe operations with a low bend force over wide temperatures. They’re also proven to protect against electromagnetic interference (EMI) with at least 85% optical coverage. Not only that, our MIL-STD-1760 shielding assemblies have a life beyond 100,000 flexes in harsh aerospace conditions without ever failing to do their job.

EASY PYLON INSTALLATION

Robust and highly flexible, our assemblies can be easily installed in limited spaces of aircraft pylons. They’re available in a variety of wire types with a smaller cross-sectional diameter compared to standard umbilicals. They can be easily attached and removed from ASI (Aircraft Store Interface) and MSI (Mission Store Interface) while operating in an NBC (Nuclear Biological Chemical) environment. Our assemblies reduce maintenance, downtime and product lifecycle costs because they don’t have to be replaced after each use.

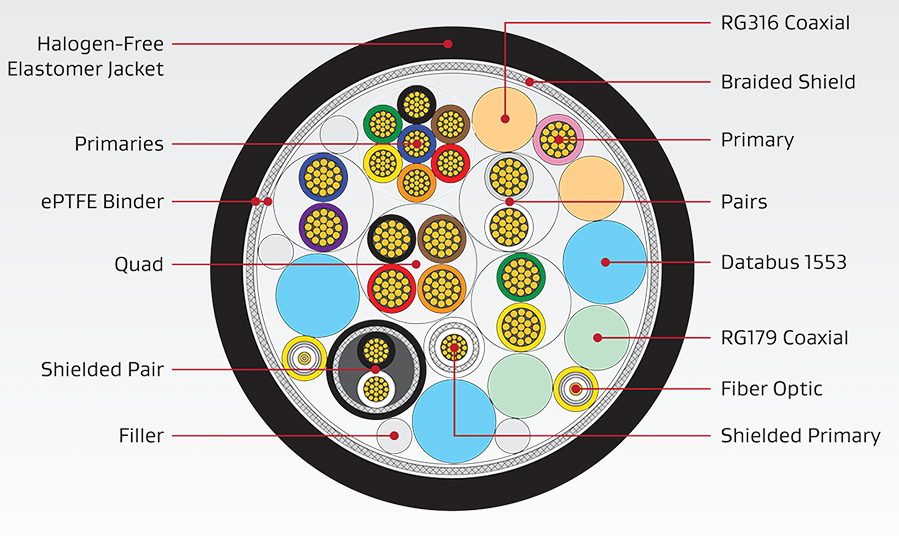

Robust, highly flexible layout of GORE MIL-STD-1760 Assemblies, Class 1 (FO) Version.

GUARANTEED 100 STORE RELEASES

We worked with L3Harris to compare the performance of our MIL-STD-1760 cable assembly with their FRCS™ against standard umbilicals that use screw-on MIL-STD-38999/31 lanyard connectors. We configured a simulator on stores with racks adjusted to represent various pylon stations accurately, including retention methods. Then, we captured the data to validate umbilical connector loads and store velocity during ejected pit releases.

Our results showed that 1 out of 10 new standard umbilicals separated within the specification limit after 100 drops. Also, 50% of the umbilicals were unserviceable after only 3 drops, and 25% failed to disconnect at all and ended up in the pit. But, our assemblies with the MIL-STD-1760 connector pinout from L3Harris delivered consistent disconnect loads and can guarantee 100 fully high-speed instrumental drops.

Program Heritage

We thoroughly test and qualify our assemblies according to the MIL-STD-1760 specification, MIL-STD-810 and other standards. They’re certified for more than 100 ejected releases and 400 manual disconnects.

GORE MIL-STD-1760 Assemblies were introduced to the North Atlantic Treaty Organization (NATO) in the 1990s. Since then, they’ve delivered 100% successful store releases on many airborne platforms, including:

- A-10 Warthog

- B-1B, B-2

- F-15E, F-16, F-35

- Gripen, GR9

- S-3B Viking

- Super Lynx, Wildcat

- Tornado GR4

- Typhoon

Features & Benefits

Compared to standard umbilicals, GORE MIL-STD-1760 Assemblies are manufactured with distinct features that make them more robust in challenging aircraft pylon conditions, including:

- sealed hybrid assembly in a highly flexible design

- chemically inert, temperature-resistant, EMI shielding materials

- a variety of wire types with smaller cross-sectional diameters

- Class I & II standard versions or customized options

Our aircraft umbilical cable assembly offers system architects and engineers a host of benefits that improve their overall performance in the harshest flight conditions, like:

- guaranteed 100 ejected releases

- superior EMI protection with at least 85% optical coverage

- excellent electrical and mechanical performance in extreme conditions

- easy installation and extended operation from proven high flex life >100,000

- fully tested, qualified and certified for 500 manual disconnects

- less maintenance, downtime and replacement costs

- a variety of connectors (standard shell size 25, 17, 15 stores with relevant inserts)

- flight-proven on many airborne platforms with 100% successful store releases

Technical Specs

These values demonstrate the mechanical and environmental performance of GORE MIL-STD-1760 Assemblies for defense aircraft.

| Mechanical / Environmental Property | GSC-01-86039-00 Class I (FO) | GSC-01-86038-00 Class I | GSC-01-85806-00 Class II |

|---|---|---|---|

| Outer Jacket Material | Halogen-Free Elastomer | Halogen-Free Elastomer | Halogen-Free Elastomer |

| Outer Jacket Color1 | Black | Black | Black |

| Conductor Plating2 | Silver-Plated Copper | Silver-Plated Copper | Silver-Plated Copper |

| Conductor Color-Coding | Individually Coded Primaries | Individually Coded Primaries | Individually Coded Primaries |

| Dielectric Material | PTFE/Expanded PTFE | PTFE/Expanded PTFE | PTFE/Expanded PTFE |

| Braid Shielding2 | Silver-Plated Copper | Silver-Plated Copper | Silver-Plated Copper |

| Braid Optical Coverage3 % | > 85 | > 85 | > 85 |

| Outer Diameter mm (in) | 18.7 (0.74) | 18.7 (0.74) | 18.3 (0.72) |

| Fiber Optic Core Type2 | OM3 (Multi-Mode, Graded Index) | — | — |

| Fiber Optic Core/Cladding/Coating | 50/125/245 | — | — |

| Fiber Optic Buffering System | Expanded PTFE 900 micron | — | — |

| Minimum Bend Radius mm (in) Static Dynamic | 46.8 (1.8) 93.5 (3.7) | 46.8 (1.8) 93.5 (3.7) | 45.8 (1.8) 91.5 (3.6) |

| Flex Life Cycles | > 100,000 | > 100,000 | > 100,000 |

| Temperature Range °C | -60 to +150 | -60 to +150 | -60 to +150 |

1 Other colors available upon request.

2 Other options available upon request.

3 Other optical coverages available upon request.

How to Buy

Flight-proven on many airborne platforms with 100% successful store releases since the 1990s, we offer Class I & II standard MIL-STD-1760 breakout cable assembly versions in a variety of wire types. To meet your specific aircraft integration requirements, we also offer bespoke and custom assembly options with MIL-STD backshells, custom backshells and molding designs.

For more information or to discuss your specic application needs and place an order, contact a Gore representative today.

Resources

Data Sheet: GORE® MIL-STD-1760 Assemblies for Defense Aircraft

Data Sheets, 2.63 MB

View all resources for GORE MIL-STD-1760 Assemblies for Defense Aircraft

Recent News

Press Release

Gore Showcases Latest Lightweight Aerospace & Defense Solutions at Paris International Air Show

Posted June 16, 2025

W. L. Gore & Associates, a global leader providing solution-oriented innovations that include future materials for aerospace, is proud to showcase its latest lightweight innovations at the Paris International Air Show, held from 16 – 22 June at Le Bourget, France.

Event

Visit Gore at AAAA to enhance mission success, survivability & safety

May 14, 2025 - May 16, 2025

Visit us at Booth 900 to experience our live demonstrations and discover how GORE® Cables and Materials enhance Army airframe and aviation systems. Reserve time now with a Gore specialist to discuss how we can help deliver solutions that support mission success, survivability and safety.

Press Release

W. L. Gore & Associates Joins Team FLRAA as a Wire and Cable Supplier for the U.S. Army’s Future Long Range Assault Aircraft Program

Posted May 13, 2025

NEWARK, Del./USA — W. L. Gore & Associates, a global leader in aerospace cables and materials, has joined Team FLRAA, bringing its technology to one of the U.S. Army’s most advanced modernization efforts.

Press Release

Bae Systems Honors W. L. Gore & Associates With a ‘partner 2 Win’ Supplier of the Year Award

Posted April 25, 2025

NEWARK, Del./USA — W. L. Gore & Associates today announced it received a Supplier of the Year award from BAE Systems’ Partner 2 Win program. Gore was selected from a pool of suppliers that delivered exceptional performance and contributions to support supply chain success for BAE Systems’ Electronic Systems sector in 2024.

Field Replacement Connector System and FRCS are trademarks of L3Harris Release & Integrated Solutions Ltd., in the U.S.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Contact Us

Related Products

Cables & Cable Assemblies

- Shielded Twisted Pair Cables for Defense Air & Land

- CAN Bus Cables for Defense Aircraft

- Ethernet Cables for Defense Air & Land

- Quad Cables for Defense Aircraft

- FireWire® Cables for Defense Aircraft

- Fibre Channel Cables for Defense Aircraft

- USB Cables for Defense Aircraft

- HDMI Cables for Defense Aircraft

- DVI Cables (Digital Only) for Defense Aircraft

- Fiber Optic Cables for Defense Air & Land

- Cable Protection Systems for Defense Aircraft

- Abrasion Resistant Cable Jacket for Defense Aircraft

Follow GORE® MIL-STD-1760 Assemblies for Defense Aircraft