GORE® Coiled Cables for Defense Land Systems

Armed forces have trusted Gore's custom cables for decades to maintain secure communication and real-time situational awareness on the battlefield. Rugged, flexible and compact, they’re proven to fight off extreme conditions while saving weight and being comfortable to wear for mission readiness, success and safety.

Contact Us

+1 800 626 7708

Germany

+49 9144 6010

+49 9144 6816 (fax)

UK

+44 1382 56 1511

+44 1382 56 1007 (fax)

Italy

+39 045 6209 209

+39 045 6209 165 (fax)

France

+33 1 5695 6565

+33 1 5695 6401 (fax)

Spain

+34 93 480 6900

+34 93 373 7850 (fax)

Sweden

+46 31 7067800

+46 31 864226 (fax)

China (Beijing)

+86 10 5707 4999

+86 10 5707 4900 (fax)

China (Shanghai)

+86 21 5172 8299

+86 21 6247 9199 (fax)

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Japan

+81 3 6746 2582

+81 3 6746 2571 (fax)

Overview

FAST INTEL & CLEAR COMMUNICATION

On the battlefield, military units rely heavily on coiled cables attached to vectronics and soldier-worn equipment to deliver real-time Intel and uphold secure communication. These cables are essential to the success of every operation, so they must never fail.

Backed by decades of proven reliability, GORE Coiled Cables offer more advantages over conventional alternatives when it comes to speed, durability and flexibility. They deliver real-time Intel and maintain secure on-the-move communication so troops can make informed tactical decisions based on optimal situational awareness.

Gore’s custom coiled cables deliver secure radio communication during operations.

We offer two versions of our military coiled cable that can be customized to meet your exact ground defense application needs and requirements:

- High-Speed Data/Video: This version significantly improves signal integrity and speed by transmitting data and video up to 10 Gb/s without failure in modern vectronics and soldier-worn equipment.

- Radio Communications: For years, the military has used this version in more than 35,000 radio systems. Soldiers trust them to keep the lines of communication secure and open at all times during operations.

MORE DURABILITY & COMFORT

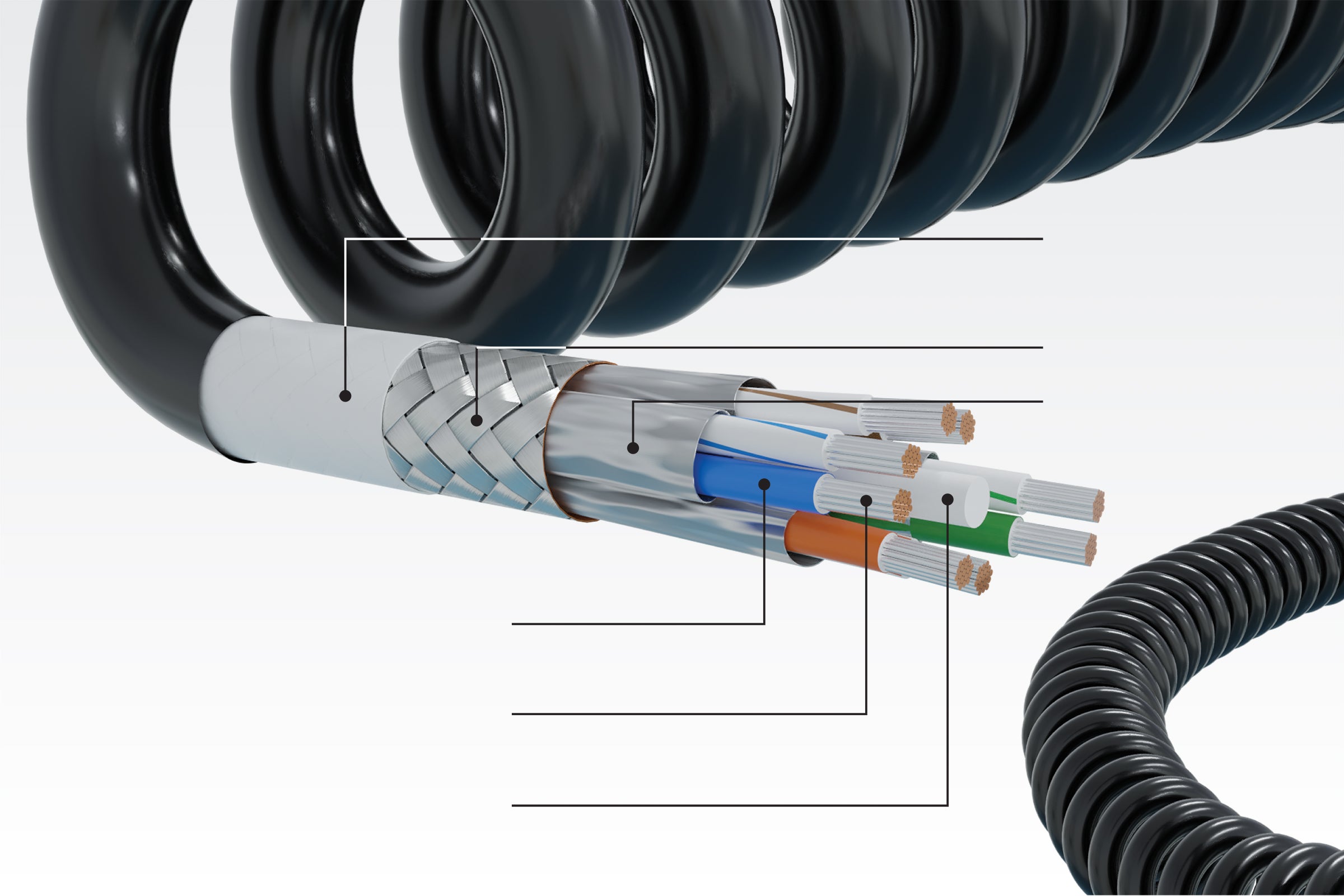

We build our harsh-environment coiled cable using engineered fluoropolymer materials to handle extreme wear and tear, which means they’ll last longer in hostile environments. They’re proven to defend against tough terrain, changing weather, fluctuating temperatures, harsh chemicals, repeated shock and vibration and more. These combat-ready coiled cables also effectively shield wires from RF interference among critical systems and equipment.

Even so, our rugged coiled cable still offers more weight savings and higher flexibility than traditional substitutes. It’s 24% smaller and 25% lighter to reduce vehicle weight and equipment load and enhance soldier comfort. This highly flexible coiled cable expands to desired lengths and effortlessly retracts back to its original form, minimizing stress on fragile wires. Soldiers can easily connect our cable to vehicular radio systems and carry-on equipment or even weave them inside their uniforms.

Rugged, lightweight design of GORE Coiled Cables (High-Speed Data/Video).

Applications

We thoroughly test and qualify GORE Coiled Cables for Defense Land Systems according to rigorous industry standards, like VG95218-11. Our mil-spec cable brings long-term durability and reliability in a variety of vehicular and solider-worn applications, like:

High-Speed Data/Video:

- Augmented reality solutions

- Digital camera/video systems

- Helmet-mounted displays

- Mission/radar systems

- Radio/communications systems

- Soldier-worn systems

- Tactical links

- Telescopic masts for optronics

- Vetronics digital networks

Radio Communications:

- Manpack radio systems

- Soldier-worn systems

- Tactical handsets/headsets

- Vehicular radio systems

Our defense coiled cables can also be terminated with a variety of high-speed connector systems and backshells, allowing designers to choose the best option for every application.

Features & Benefits

GORE Coiled Cables are engineered with unique features that make them more durable against challenging environmental factors and in-vehicle conditions, including:

- temperature- and abrasion-resistant materials

- chemically inert and EMI shielding materials

- compact, highly flexible cable construction

Our military-grade coiled cables provide vehicle system architects and engineers with many benefits that improve electrical, mechanical and environmental performance such as:

- reliable signals for high-speed data/video transmission up to 10 Gbps

- secure, clear on-the-move communication among military units

- excellent shielding effectiveness for less RF interference among systems

- rugged protection against terrain, weather, temperatures, vibration and more

- less weight and more comfort with 24% smaller and 25% lighter cable design

- highly flexible expanding to desired lengths and retracting to original form without effort

- proven long-term product life compared to conventional coiled cables

- compatible with a variety of high-speed connector systems and backshells

Technical Specs

These values demonstrate the mechanical and environmental performance of GORE Coiled Cables (High-Speed Data/Video) for defense land systems.

| Mechanical / Environmental Property | Value |

|---|---|

| Jacket Material | Thermoplastic Elastomer |

| Jacket Color | Black (Laser Markable) |

| Conductor | Silver-Plated Copper or SPC Alloy |

| Conductor Color-Coding | Solid Blue & White / Blue Stripe Solid Orange & White / Orange Stripe Solid Green & White / Green Stripe Solid Brown & White / Brown Stripe |

| Dielectric Material | Expanded PTFE/PTFE |

| Temperature Range (°C) | -40 to +100 |

How to Buy

The military continues to rely on GORE Coiled Cables over conventional alternatives for delivering the speed, durability, reliability and comfort necessary to ensure mission readiness, success and safety. Call us today to help you customize and order a military-grade coiled cable based on your precise high-speed data and video requirements or radio communication specifications.

Learn more about our entire portfolio of high-performance cable solutions that meet the defense industry’s performance expectations now and for the future.

Resources

Data Sheet: GORE® Coiled Cables (Radio Communications) for Defense Land Systems

Data Sheets, 535.03 KB

Data Sheet: GORE® Coiled Cables (High-Speed Data/Video) for Defense Land Systems

Data Sheets, 819.67 KB

View all resources for GORE Coiled Cables for Defense Land Systems

Recent News

Press Release

Bae Systems Honors W. L. Gore & Associates With a ‘partner 2 Win’ Supplier of the Year Award

Posted April 25, 2025

NEWARK, Del./USA — W. L. Gore & Associates today announced it received a Supplier of the Year award from BAE Systems’ Partner 2 Win program. Gore was selected from a pool of suppliers that delivered exceptional performance and contributions to support supply chain success for BAE Systems’ Electronic Systems sector in 2024.

Gore will be at the International Defense and Security Fair (FEINDEF) in May to show you first-hand the future of high-speed data cables and how you could benefit from our field-proven technologies in the most demanding defense environments.

Visit Hall 5A H215 at this year’s show in Paris, France, from June 17-24 to check out GORE® High Speed Data Cables that ensure mission success, survivability and safety. Reserve time now for a private meeting with a Gore specialist at the show to talk about your latest system design challenges and future needs.

Press Release

W. L. GORE & ASSOCIATES TO PRESENT NEW MOSA PAPER AT GVSETS CONFERENCE

Posted August 11, 2023

W. L. Gore & Associates (Gore) will present a new Modular Open Systems Approach (MOSA) technical paper at the Ground Vehicle Systems Engineering & Technology Symposium & Modernization Update (GVSETS) on Tuesday, August 15, in Novi, Mich.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Contact Us

Related Products

Cables & Cable Assemblies

- Shielded Twisted Pair Cables for Defense Air & Land

- CAN Bus Cables for Defense Land Systems

- Ethernet Cables for Defense Air & Land

- Quad Cables for Defense Land Systems

- USB Cables for Defense Land Systems

- HDMI Cables for Defense Land Systems

- DVI Cables (Digital Only) for Defense Land Systems

- Fiber Optic Cables for Defense Air & Land

- Coaxial Cables for Defense Land Systems

- Tethered Drone Cables for Commercial & Defense

- Cable Protection Systems for Defense Land Systems

- Abrasion Resistant Cable Jacket for Defense Land Systems

Follow GORE® Coiled Cables for Defense Land Systems