GORE® Fibre Channel Cables for Defense Aircraft

A durable, low-dielectric cable geometry that maximizes the performance of quadrax designs for more protection and weight savings than alternatives. Proven on many airborne platforms, these high-speed interconnects enhance noise immunity, improve EMI suppression and maintain reliable signals because successful missions depend on constant real-time data transfer.

Contact Us

+1 800 626 7708

Germany

+49 9144 6010

+49 9144 6816 (fax)

UK

+44 1382 56 1511

+44 1382 56 1007 (fax)

Italy

+39 045 6209 209

+39 045 6209 165 (fax)

France

+33 1 5695 6565

+33 1 5695 6401 (fax)

Spain

+34 93 480 6900

+34 93 373 7850 (fax)

Sweden

+46 31 7067800

+46 31 864226 (fax)

China (Beijing)

+86 10 5707 4999

+86 10 5707 4900 (fax)

China (Shanghai)

+86 21 5172 8299

+86 21 6247 9199 (fax)

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Japan

+81 3 6746 2582

+81 3 6746 2571 (fax)

Overview

RELIABLE SIGNAL INTEGRITY AT HIGH DATA RATES

Today’s defense aircraft require cables to carry loads of data at faster speeds on avionics digital networks to ensure missions succeed. Since aviation cables play a key role in system performance, they must outlast complex maintenance and environmental conditions, like tricky wiring, fluctuating temperatures and harsh contaminants.

GORE Fibre Channel Cables are a reliable, low-dielectric solution to combat these challenges. They’re proven to maintain consistent signal integrity at high data rates up to 1 GHz. Featuring a balanced quadrax design with field-cancellation properties, they can transmit two different signals within the same shield without interfering with each other. Our high-speed interconnects are also proven to enhance noise immunity and EMI suppression.

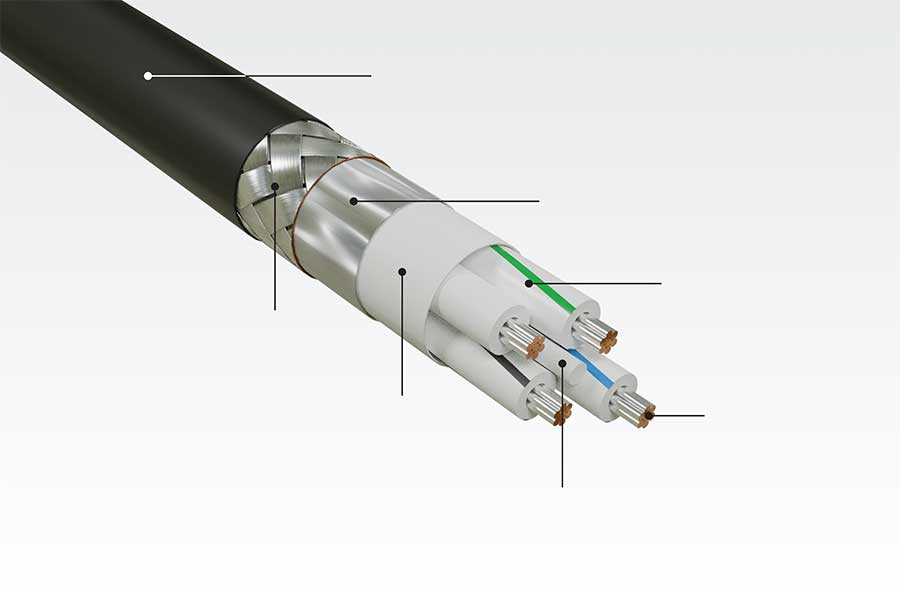

Low-dielectric cable geometry

SAVE WEIGHT & BOOST DURABILITY

We originally invented this low-dielectric quadrax cable geometry that saves more weight in aircraft than other cable designs. Compared to dual twisted pair cables, our fibre channel cables are about 40% smaller, making them naturally lighter. Our design is also highly flexible with tight bending to simplify and expedite aircraft wiring in narrow system configurations.

Just because they’re smaller and lighter doesn’t mean they’re fragile like other cable materials. We also boost durability with our uniquely engineered fluoropolymers that resist hazardous aircraft environments and extreme flight conditions.

Tough construction of GORE Fibre Channel Cables.

Applications & Connectors

GORE Fibre Channel Cables have been proven and trusted on the F-16, F-18 and AV8B, making them a reliable interconnect for critical applications, like:

- active electronically scanned arrays (AESA)

- mission systems

- flight management systems

- tactical aircraft moving maps

Our cables can be terminated with a variety of leading high-speed aerospace and defense connector systems and backshells, like ARINC and MIL-STD-38999 with size 8 contacts.

They can also be mated with commercially available connectors to create assemblies and optimize performance in the smallest possible package. Benefits include:

- Insert configurations maintain quadrax geometry through connector interface

- Improved Z° match minimizes reflections for clean eye patterns

- Standard size 22D contacts provide high reliability and ease of use

- Series 3 coupling provides enhanced EMI performance

Features & Benefits

We build GORE Fibre Channel Cables with rugged features proven to resist extreme aircraft conditions and environmental factors, including:

- original inventor of reduced quadrax design

- temperature- and abrasion-resistant materials

- chemically inert materials

For system architects and engineers, our aviation interconnects provide many benefits that improve their overall performance in aircraft, like:

- consistent signals up to 1 GHz with controlled impedance at 150 ohms

- enhanced noise immunity and EMI suppression

- resist hazardous aircraft environments and extreme flight conditions

- low-dielectric design is around 40% smaller than dual twisted pair constructions

- more weight savings in aircraft than other cable designs

- simpler and faster aircraft wiring from high flexibility and tight bending ability

- proven on many airborne platforms, like the F-16, F-18 and AV8B

- compatible with a variety of high-speed connector systems and backshells

Technical Specs & Drawing

These values demonstrate the electrical, mechanical and environmental performance of GORE Fibre Channel Cables for defense aircraft. Download our data sheet for more cable characteristics, qualifications and part number. Also, fill out a short form for instant access to the drawing.

| Elec./Mech./Environ. Property | Value |

|---|---|

| Signal Transmission Speed GHz | Up to 1 |

| Standard Impedance Ohms | 150 ± 10 |

| Typical Operating Voltage Rating V | < 15 |

| Nominal Velocity of Propagation % | 87 |

| Nominal Time Delay ns/m (ns/ft) | 4.0 (1.22) |

| Capacitance pF/m (pF/ft) | 28.2 (8.6) |

| Typical Skew Within Pair ps/m (ps/ft) | 3.0 (0.9) |

| Dielectric Withstanding Voltage Vrms Conductor-to-Conductor Conductor-to-Shield | 1500 1000 |

| Jacket Material | FEP |

| Jacket Color | Black |

| Conductor | Silver-Plated Copper Alloy |

| Conductor Color-Coding | Black/White Stripe, Blue/White Stripe, Green/White Stripe, Solid White |

| Dielectric Material | Expanded PTFE |

| Temperature Range °C | -65 to +200 |

Get Samples or Buy

With toughness and reliable signal transmission at higher data rates, GORE Fibre Channel Cables have been trusted by aircrews and proven on many airborne defense platforms. Order a complimentary sample of our pre-qualified cable to determine if this unique quadrax design is compatible with your aircraft application.

If you’re ready to purchase our fibre channel cable now, connect with an approved distributor for in-stock availability. Or, contact us today to talk about your specific application needs and requirements.

Resources

Recent News

Press Release

Gore Showcases Latest Lightweight Aerospace & Defense Solutions at Paris International Air Show

Posted June 16, 2025

W. L. Gore & Associates, a global leader providing solution-oriented innovations that include future materials for aerospace, is proud to showcase its latest lightweight innovations at the Paris International Air Show, held from 16 – 22 June at Le Bourget, France.

Event

Visit Gore at AAAA to enhance mission success, survivability & safety

May 14, 2025 - May 16, 2025

Visit us at Booth 900 to experience our live demonstrations and discover how GORE® Cables and Materials enhance Army airframe and aviation systems. Reserve time now with a Gore specialist to discuss how we can help deliver solutions that support mission success, survivability and safety.

Press Release

W. L. Gore & Associates Joins Team FLRAA as a Wire and Cable Supplier for the U.S. Army’s Future Long Range Assault Aircraft Program

Posted May 13, 2025

NEWARK, Del./USA — W. L. Gore & Associates, a global leader in aerospace cables and materials, has joined Team FLRAA, bringing its technology to one of the U.S. Army’s most advanced modernization efforts.

Press Release

Bae Systems Honors W. L. Gore & Associates With a ‘partner 2 Win’ Supplier of the Year Award

Posted April 25, 2025

NEWARK, Del./USA — W. L. Gore & Associates today announced it received a Supplier of the Year award from BAE Systems’ Partner 2 Win program. Gore was selected from a pool of suppliers that delivered exceptional performance and contributions to support supply chain success for BAE Systems’ Electronic Systems sector in 2024.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Contact Us

Related Products

Cables & Cable Assemblies

- Shielded Twisted Pair Cables for Defense Air & Land

- CAN Bus Cables for Defense Aircraft

- Ethernet Cables for Defense Air & Land

- Quad Cables for Defense Aircraft

- FireWire® Cables for Defense Aircraft

- USB Cables for Defense Aircraft

- HDMI Cables for Defense Aircraft

- DVI Cables (Digital Only) for Defense Aircraft

- Fiber Optic Cables for Defense Air & Land

- MIL-STD-1760 Assemblies for Defense Aircraft

- Cable Protection Systems for Defense Aircraft

- Abrasion Resistant Cable Jacket for Defense Aircraft

Follow GORE® Fibre Channel Cables for Defense Aircraft