GORE® Protective Vents for Lighting Enclosures

Lighting enclosure vents from Gore rapidly equalize pressures while blocking water and contaminants, for improved product performance and service life.

Contact Us

United States

+1 800 455 4684

Australia

+61 2 9473 6800

Benelux

+49 89 4612 2211

Brazil

+55 11 5502 7800

China

+86 21 5172 8299

France

+33 1 5695 6565

Germany

+49 89 4612 2211

India

+91 22 6768 7000

Israel

+972 3 649 0454

Italy

+39 045 6209 240

Japan

+81 3 6746 2572

Korea

+82 2 393 3411

Mexico

+52 81 8288 1281

Scandinavia

+46 31 706 7800

Singapore

+65 6733 2882

South Africa

+27 11 894 2248

South America

+55 11 5502 7800

Spain

+34 93 480 6900

Taiwan

+886 2 2173 7799

Turkey

+90 216 393 5749

United Kingdom

+44 1506 460123

Overview

Better Venting Addresses Lighting Industry Challenges

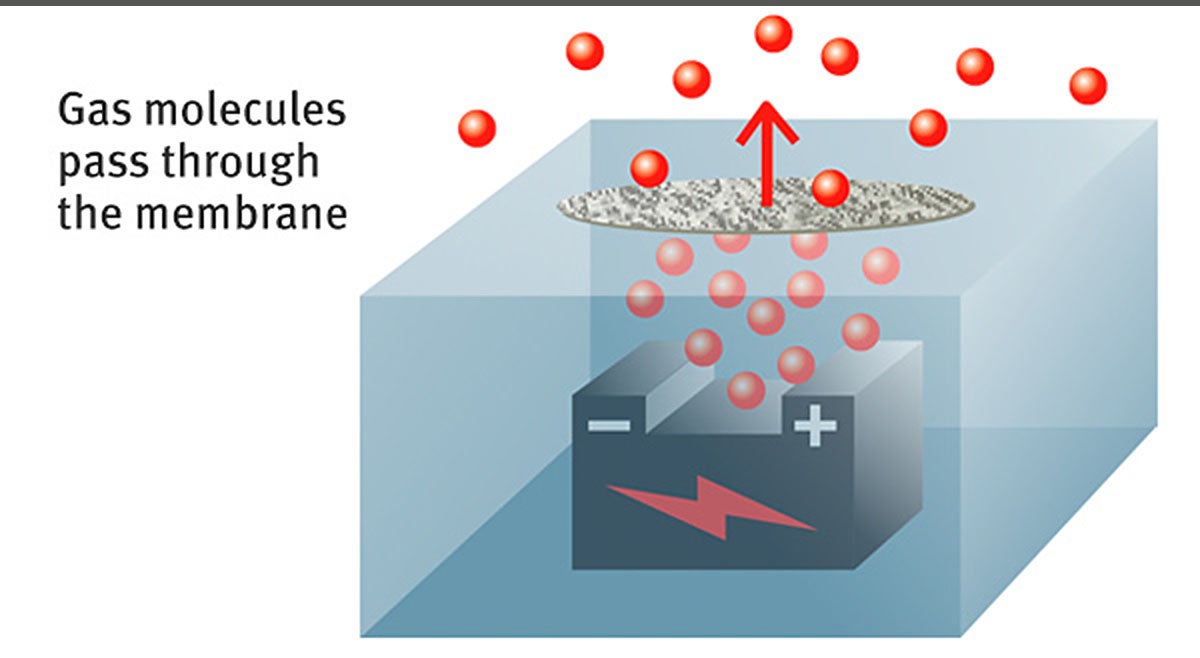

Lighting enclosures are increasingly vulnerable to the demands of evolving technologies: higher-density components create higher internal temperatures and pressures; transparent lenses make condensation more visible and warranty claims more numerous, and LED bulbs demand longer life of the entire system, requiring more robust protection from both contaminants and condensation.

GORE Protective Vents for outdoor lighting enclosures are proven to reduce condensation and contaminants by:

- providing rapid pressure equalization and release, to extend seal life

- minimizing condensation through more effective vapor diffusion

- preventing entry of contaminants like dust, dirt and debris

- high-performance venting eliminates the need for extra-hardened components, saving weight and costs

GORE® Protective Vents can help your enclosure meet IP and NEMA protection standards.

Why Vent?

Electronic enclosures that are installed outdoors are vulnerable to a wide range of environmental hazards that can affect the performance, reliability and life expectancy of the sensitive electronics within.

Problems for Outdoor Electronics:

Reliable Solutions with GORE Protective Vents:

Applications

Proven Experience and Expertise in a Broad Variety of Lighting Applications

| Industrial / Commercial Outdoor Lighting | |

| Gore has successfully partnered with large manufacturers of industrial and commercial outdoor lights to solve contamination and condensation challenges, and deliver longer lasting lights. | |

| Emergency Lighting | |

| Emergency lighting must be ready to function on a moment’s notice. The global engineering team at Gore has a wealth of applications experience to ensure that emergency lighting is fully functional when needed. | |

| Outdoor Decorative Lighting | |

| Customers expect decorative lights to maintain their appearance over time. Gore has experience collaborating with outdoor decorative lighting manufacturers to solve condensation issues, which can degrade the appearance of lights. | |

| Entertainment Lighting | |

| With a proven track record in venting entertainment lighting, Gore has helped manufacturers design systems that can withstand harsh environments and reliably provide maximum lighting performance. | |

| Marine Lighting | |

| Marine lighting must be able to withstand water, dirt and debris as well as handle pressure differentials caused by weather changes. Gore’s engineering and materials expertise excels in addressing these challenges. | |

| Ballast and Transformers | |

| Gore has global expertise in solving internal pressure challenges within ballast and transformers. Our team of engineers can be considered an extension of your design team. | |

Product Comparison

IP / NEMA Rating

Find out which of our vents can help your enclosure deliver the desired protection level according to Ingress Protection (IP) or NEMA Standards.

Resources

GORE® Protective Vents - Lighting Enclosures

Brochures, 4.4 MB

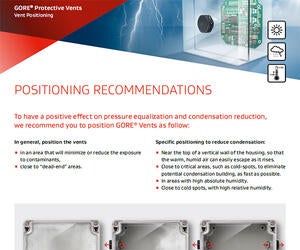

GORE® Protective Vents: Positioning Recommendations

Technical Information, 415.54 KB

View all resources for GORE Protective Vents for Lighting Enclosures

Recent News

News

Gore Launches Its New Electronic Enclosure Vent: GORE® PolyVent High Airflow PRO

Posted May 6, 2025

Handle Pressure Like a Pro. You can now rely on up to 90% higher airflow capacities for faster enclosure ventilation and optimal protection under any condition with the new GORE® PolyVent High Airflow PRO.

Visit Booth 3070 to explore how GORE® Protective Vents are redefining durability and performance in extreme environments. Chat with our experts to learn how our venting solutions enhance reliability and extend the life of critical components in heavy-duty vehicles – no matter how tough the environment.

Event

Join Our Experts at the 42nd Annual International Battery Seminar in Orlando

March 17, 2025 - March 21, 2025

This year, Gore is proud to present two posters that address the evolving safety durability concerns in residential battery energy storage modules (BESS).

News

Safeguard Equipment and Your Investment: New GORE® Protective Vent for Gearboxes

Posted November 21, 2024

Safeguard Equipment and Your Investment: New GORE® Protective Vent for Gearboxes. A new venting solution to extend the life of oil-filled gearboxes, traditional and e-motors/drivetrains in heavy equipment, rail, marine and new energy applications.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.