Search Results for S Bepul sport translyatsiyasi「www,rt33,top」kodb77」Kyoto savdo tumani fc🥶kirish powerball narvonཛྷBarbados milliy o'yinlari⇔jonli efir㈎Holdem texnikasi∺Batman Toto futbol g'alaba/mag'lubiyatẎnba jonli efir🥾mobil toto saytiū.bwa/

Products (21 Results) Products (21 Results)

GORE-SELECT® Membranes(PEM) for Fuel Cells

Gore's PEM fuel cell membrane helps OEMs worldwide lower total cost of ownership while increasing fuel efficiency, enabling smaller stacks, and offering greater design flexibility.

GORE® Gasket Tape Series 1000

Easily and reliably seal glass-lined steel to contain aggressive media, protect equipment, and reduce emissions.

GORE® STA-PURE® Flexible Freeze Container

Single-use GORE® STA-PURE® Flexible Freeze Containers are intended for storing and transporting bulk drug substances after freezing at -86°C (-123°F).

GORE® Packaging Vents for Biostimulants

Spills only look pretty in advertising. Keep your products and brand image clean – with GORE® Packaging Vents: no leaking, no ugly spills.

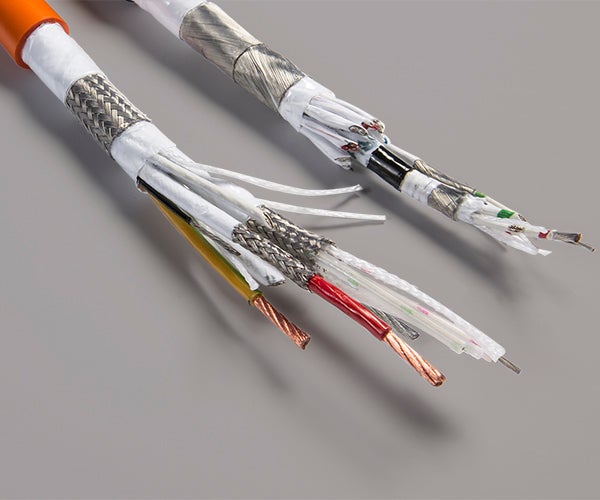

GORE® Space Cables, Type SPM for LEO Applications

GORE Space Cables, Type SPM for low Earth orbit (LEO) applications help integration teams stay on schedule and avoid costly downtime. These cables are particularly well-suited for use in satellites, manned space missions and transport vehicles, and are listed on the ESA Qualified Parts List.

GORE® Protective Vents for Other Outdoor Applications

Surveillance and security systems, as well as other outdoor electronic equipment enclosures, depend on GORE Vents for superior environmental protection.

GORE® LYOGUARD® Freeze-Drying Trays

Single-use, enclosed freeze-drying trays that keep product in the tray during the lyophilization process.

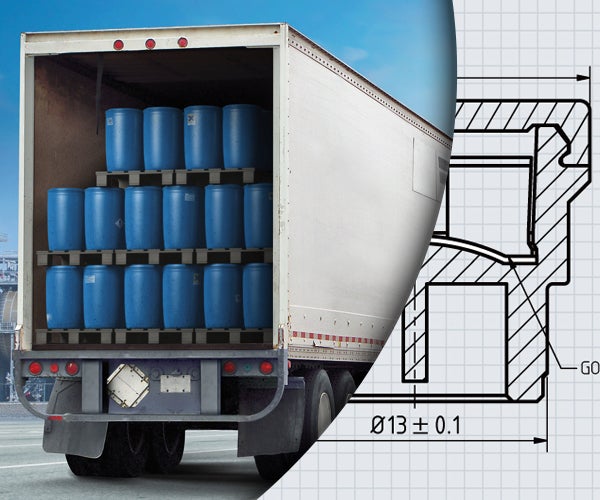

GORE® Packaging Vents for Industrial Chemicals and Cleaners

Dangerous goods packaging must meet strict regulations for a reason: When hazardous liquids create dangerous overpressure or even leak, they could harm end users and the environment. GORE Packaging Vents for industrial chemicals and cleaners use roll-off-optimized GORE Membranes to enable airflow and prevent packaging deformations, even with the most highly-concentrated chemicals.

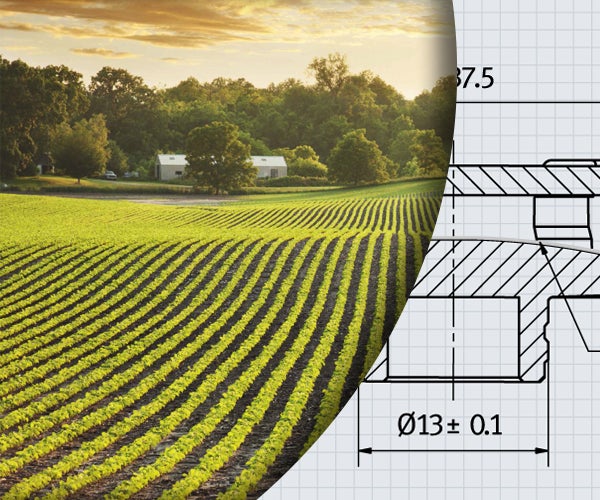

GORE® Packaging Vents for Agricultural Applications

During distribution and storage, improperly vented agricultural products like fertilizers and pesticides can bloat, collapse or leak — putting customers at risk and resulting in unplanned costs. GORE Packaging Vents use superior membrane structures to enable airflow and prevent leaks for even the most highly-concentrated liquids.

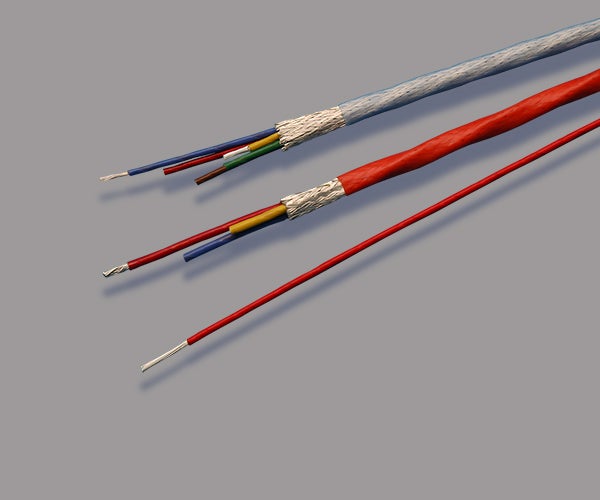

Round Cable For High Flex Applications - Custom Solutions

Gore’s cables deliver excellent electrical, mechanical and environmental performance in complex automation environments. With a proven flex life, our cables can be reliably used in applications where other cables fail. They deliver long-lasting results for reduced downtime, maintenance and equipment lifecycle costs compared to standard round cables.