GORE® LYOGUARD® Lyophilization Trays

Single-use, enclosed freeze-drying trays that keep product in the tray during the lyophilization process.

Protect Your Operators and Eliminate Tray Cleaning

For over 20 years, manufacturers have trusted GORE Lyoguard Trays to help minimize the risk of exposure to liquid or lyophilized active pharmaceutical ingredient (API) and Highly-Potent APIs, and enable operators to spend less time worrying about product ejection and cleaning.

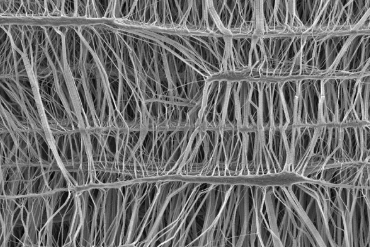

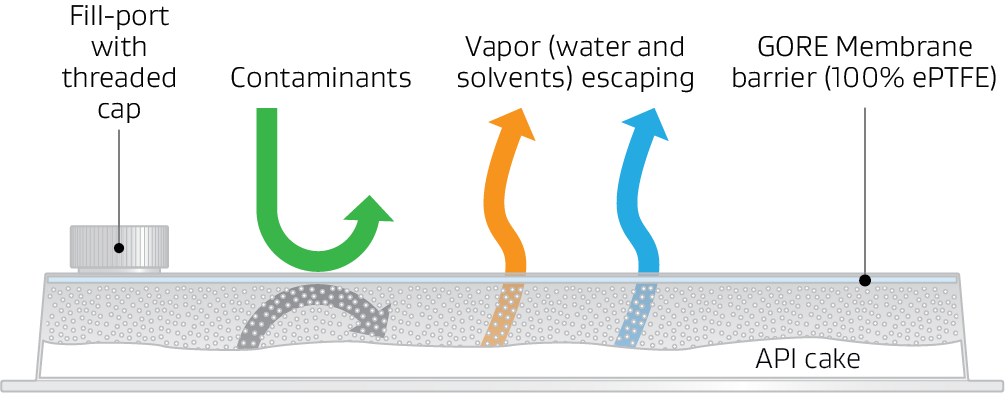

These fully enclosed disposable trays are ideal bulk lyophilization containers, because the GORE Membrane — an integrated 100% ePTFE tray cover — can enable improved process efficiencies and yields, and reduced risk of operator exposure.

GORE LYOGUARD Trays vs Competitors

| GORE LYOGUARD Trays | Tray Covers or Improvised Wraps | |

|---|---|---|

| Handling | Integrated top, no need for separate covers | Require extra handling to install/remove |

| Cleaning | Covered trays are single-use; no cleaning | Require extra labor to clean after use |

| Spills/Fly-Outs | Effectively block contents from escaping | Vulnerable to leaks, spills, fly-outs |

| Contamination | Effectively reduces risk of product contamination | Vulnerable to external contaminants |

| GORE LYOGUARD Trays | Open Stainless-Steel Trays | |

|---|---|---|

| Filling Requirements | The integrated top membrane minimizes splash risk, eliminating the need for special precautions, and allows faster filling for improved productivity | Low speed filling in Class-A environment, close to dryer loading area, required to minimize splashing |

| Tray Handling | The integrated top membrane protects the product, reducing splash and fly-out risks, ensuring flexibility during filling, loading, unloading, and transport. Trays are stackable for transport and post-lyophilization storage | Requires multiple slow and careful manipulations to fill, load, download, and transport open trays without incident. Trays cannot be stacked |

| Impact on Thermal Transfer | Flexible, thin film base provides uniform tray-to-shelf contact, minimizing air gaps and improving thermal transfer | Stainless-steel trays may warp creating inconsistent tray-to-shelf contact, resulting in poor thermal transfer |

| Contamination | Efficient barrier protection effectively reduces risk of contamination | Open stainless-steel trays have no barrier protection to reduce the risk of contamination |

| Fly-Out | Reduced fly-out risk ensures high productivity and yields, with fewer unplanned clean-ups to disrupt workflow | Prone to fly-out, leading to reduced production yields and increased cleanup needs |

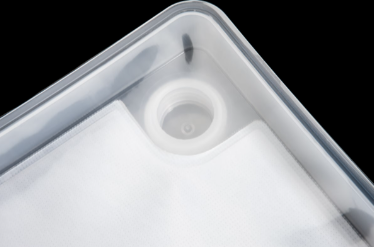

| Product Recovery | Fast, simple recovery process: use integrated fill-port or cut bottom film to recover product | Spatula use requires a slow, careful process |

| Remedial Cleanings | By protecting against spills and fly-outs, the need for additional remedial cleanings or validations is effectively reduced | After spills or fly-out, cleaning of freeze dryer requires additional validation, consuming worker time and resources |

Learn More About GORE LYOGUARD Below

An Innovation for Lyophilization

Open stainless-steel trays are the norm for lyophilization, but that doesn’t mean they’re ideal. Introduce yourself to the only single-use, self-contained tray on the market. GORE LYOGUARD Freeze-Drying Trays offer a number of benefits for the synthesis of peptides and oligonucleotides.

Contain Product and Costs

In traditional freeze-drying processes using open trays, drug product can escape the tray into the lyophilization chamber. GORE LYOGUARD Freeze-Drying Trays help prevent product ejection for less mess and less product loss.

Easier Filling, Less Spilling

Filling open trays can leads to product spills, which creates messes, wastes product and exposes workers to potentially hazardous APIs. GORE LYOGUARD Freeze-Drying Trays feature an innovative top membrane and spout that makes tray filling easier and safer.

Get a Handle on Handling

Stainless-steel trays are challenging to handle because drug product can spill, exposing operators to active pharmaceutical ingredients. GORE LYOGUARD Freeze-Drying Trays enclose liquids completely, preventing spills and making tray handling more efficient.

Never Clean Another Tray

Single-use lyophilization trays don’t need to be cleaned, which saves pharmaceutical companies and drug manufacturers time and money. GORE LYOGUARD Freeze-Drying Trays are the only single-use, self-contained tray on the market.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 328 4623

Have questions or unique requirements?

Our experts are here to guide you.