GORE® STA-PURE® Pump Tubing, Series PFL

Avert tubing failure due to aggressive chemicals with this composite tubing structure that withstands clean-in-place (CIP) / steam-in-place (SIP) and enables consistent flow throughout processing.

Durable Tubing for Reliable Performance in Aggressive Chemical Applications

Challenging pharmaceutical and biopharmaceutical processes demand high performance solutions — including durable peristaltic pump tubing that reliably withstands aggressive chemicals and protects against catastrophic failure.

Silicone pump tubing has limited resistance to chemicals like organic solvents. But the patented composite of GORE STA-PURE Pump Tubing, Series PFL is engineered to resist aggressive chemicals including organic solvents. Series PFL tubing also delivers consistent flow rates at pressures up to 60 psig and is designed to work seamlessly in your existing processes.

Series PFL

Chemically Inert

- Provides better chemical compatibility than silicone or thermoplastic elastomer (TPE) tubing

- Performs reliably with common organic solvents

- Minimizes incidence of premature rupture

Compatible with CIP/SIP and Autoclave Sterilization

- Provides a flexible solution for industry-standard cleaning/sterilization procedures

- Supports sterile fluid processing

Available in Standard Sizes

- Retrofits easily to industry-standard peristaltic pumps. See a complete list of all our standard dimensions.

High Resilience

- Maintains process stability

- Delivers consistent flow rate

Aggressive Chemical Resistance

Series PFL was tested for durability to ensure reliable performance with aggressive chemicals as compared to deionized (DI) water. Twelve (12) samples were tested in a Watson-Marlow 600 Series two-roller peristaltic pump at a discharge pressure of 10 psig and speed of 165 rpm. The samples had a nominal ID of 12.7 mm and nominal WT of 3.2 mm. The samples were subjected to CIP/SIP conditions for 5 cycles (3 before and 2 during testing). Working fluids consisted of DI water (6 samples), and 99% concentrations of acetic acid, acetone, and ethanol (2 samples each). The mean tube life of the samples that underwent pumping of organic solvents was not significantly different from the samples that underwent pumping of DI water.

Technical Specifications

Unlike silicone tubing, Series PFL is manufactured with a patented composite of platinum-cured perfluoroelastomer and expanded polytetrafluoroethylene (ePTFE) for increased reliability with aggressive chemicals in peristaltic pumps.

| Materials and Construction | A patented composite of platinum-cured perfluororelastomer and expanded polytetrafluoroethylene (ePTFE) |

|---|---|

| Fluid Contact Surface | Platinum-cured perfluoroelastomer |

| Performance Testing | Series PFL was tested for durability in peristaltic pumps over a wide range of discharge pressures and working fluids (see table) |

Series PFL was tested in peristaltic pumps over a wide range of discharge pressures and working fluids (see table).

| Discharge Pressure (psig) | Tube Life (hours) |

|---|---|

| 10 | >330b |

| 60 | 85 ± 48c |

a Continuous pumping of room temperature deionized water in Watson-Marlow 500 and 600 Series peristaltic pumps. The 500 Series pumps were used for testing at 60 psig with pump head speed of 220 rpm (two rollers). The 600 Series pumps were used for testing at 10 psig with pump head speed of 165 rpm (two rollers). Samples selected represent the worst-case configuration of pump and tube size based on mechanical stresses imposed by the pump on the tube.

b Tube size = 12.7 mm (ID) x 3.2 mm (WT); When testing was terminated at a minimum of 330 hours, all 6 samples were performing without failure. Failure is defined as rupture, leakage, sustained flow reduction of 25 percent or more, or inability to sustain operating pressure. Tubing was subjected to conditions similar to 5 CIP/SIP cycles (3 before and 2 during testing).

c Tube size = 6.4 mm (ID) x 2.4 mm (WT); 6 samples were tested until failure as defined in (b) above. The operating life until failure is presented as the average and standard deviation for all samples. The minimum observed value was 28 hours. Before testing, tubing was subjected to conditions similar to 1 CIP/SIP cycle.

| Sterilization |

|

|---|---|

| Biocompatibility |

|

| Manufacturing Environment |

|

| Quality Standards |

|

| Inspection |

|

| Storage/Shelf Life |

|

Series PFL products are available in standard sizes through select channel partners. To request a Validation Guide, or to connect with a trusted channel partner to discuss your specific needs, contact us.

Standard size ranges

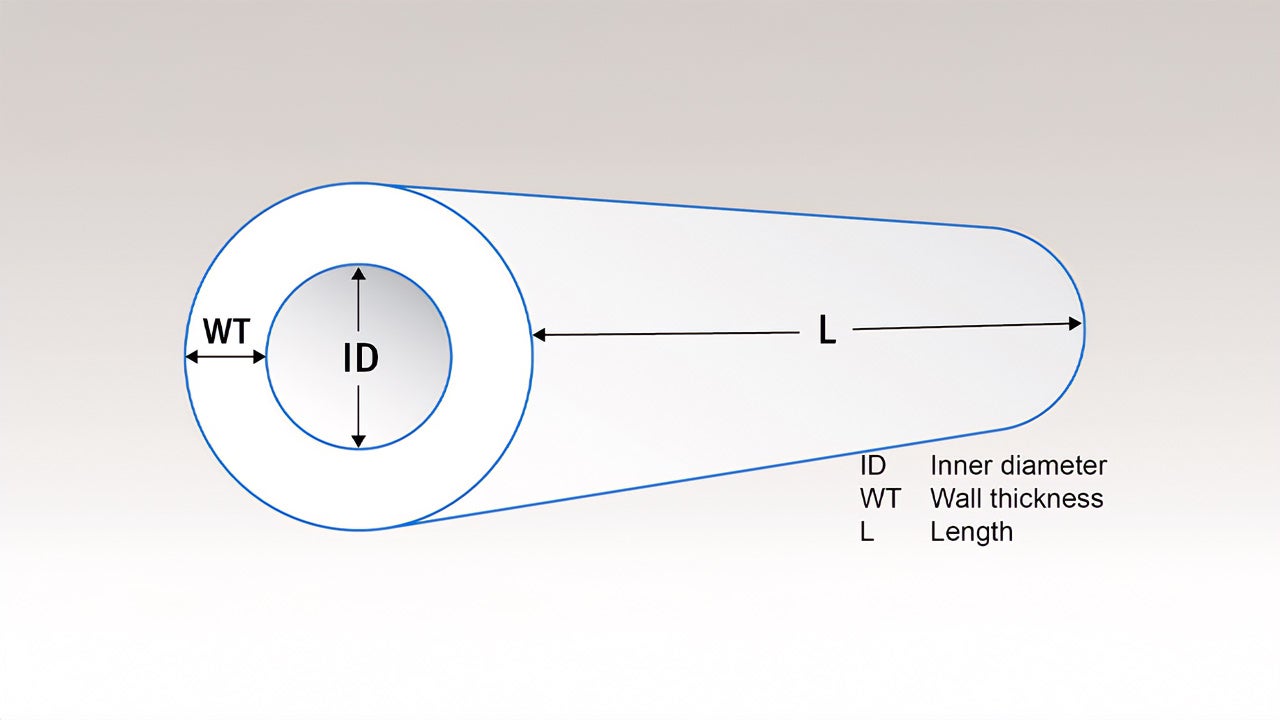

| Example | Z | A | 12 | FE |

|---|---|---|---|---|

| Attribute | Inner Diameter (ID) | Wall thickness (WT) | Length (L) | Series PFL |

| Nominal Range | 1.6 - 25.4mm (0.063 - 1.0 in) | 0.8 - 4.8 mm (0.031 - 0.19 in) | 304.8 - 609.6 mm (12.0 - 24.0 in) | FE |

Example: ZA12FE is a Series PFL tube with a nominal ID of 3.2 mm (0.13 in), WT of 1.6 mm (0.063 in), and L of 304.8mm (12 in).

| Nominal Dimensions | Specifications | ||||

|---|---|---|---|---|---|

| Gore Part Number | Inner Diameter (mm) | Wall Thickness (mm) | Inner Diameter (mm) | Wall Thickness (mm) | Length (mm) |

| XZ14FE | 2.8 | 0.8 | 2.80 ± 0.20 | 0.90 ± 0.10 | 355.6 ± 3.0 |

| YA12FE | 1.6 | 1.6 | 1.60 ± 0.20 | 1.70 ± 0.20 | 304.8 ± 3.0 |

| YA14FE | 1.6 | 1.6 | 1.60 ± 0.20 | 1.70 ± 0.20 | 355.6 ± 3.0 |

| ZA12FE | 3.2 | 1.6 | 3.20 ± 0.25 | 1.70 ± 0.20 | 304.8 ± 3.0 |

| ZA14FE | 3.2 | 1.6 | 3.20 ± 0.25 | 1.70 ± 0.20 | 355.6 ± 3.0 |

| AA12FE | 4.8 | 1.6 | 4.70 ± 0.25 | 1.70 ± 0.20 | 304.8 ± 3.0 |

| AA14FE | 4.8 | 1.6 | 4.70 ± 0.25 | 1.70 ± 0.20 | 355.6 ± 3.0 |

| BA12FE | 6.4 | 1.6 | 6.30 ± 0.25 | 1.70 ± 0.20 | 304.8 ± 3.0 |

| BA14FE | 6.4 | 1.6 | 6.30 ± 0.25 | 1.70 ± 0.20 | 355.6 ± 3.0 |

| CA12FE | 8.0 | 1.6 | 7.90 ± 0.25 | 1.70 ± 0.20 | 304.8 ± 3.0 |

| CA14FE | 8.0 | 1.6 | 7.90 ± 0.25 | 1.70 ± 0.20 | 355.6 ± 3.0 |

| YB14FE | 1.6 | 2.4 | 1.60 ± 0.20 | 2.50 ± 0.20 | 355.6 ± 3.0 |

| ZB14FE | 3.2 | 2.4 | 3.20 ± 0.25 | 2.50 ± 0.20 | 355.6 ± 3.0 |

| AB14FE | 4.8 | 2.4 | 4.70 ± 0.25 | 2.50 ± 0.20 | 355.6 ± 3.0 |

| BB14FE | 6.4 | 2.4 | 6.30 ± 0.25 | 2.50 ± 0.20 | 355.6 ± 3.0 |

| CB14FE | 8.0 | 2.4 | 7.90 ± 0.25 | 2.50 ± 0.20 | 355.6 ± 3.0 |

| DB24FE | 9.5 | 2.4 | 9.40 ± 0.25 | 2.50 ± 0.20 | 609.6 ± 3.0 |

| BC24FE | 6.4 | 3.2 | 6.30 ± 0.25 | 3.30 ± 0.20 | 609.6 ± 3.0 |

| DC24FE | 9.5 | 3.2 | 9.40 ± 0.25 | 3.30 ± 0.20 | 609.6 ± 3.0 |

| EC24FE | 12.7 | 3.2 | 12.50 ± 0.25 | 3.30 ± 0.20 | 609.6 ± 3.0 |

| FC24FE | 15.9 | 3.2 | 15.70 ± 0.50 | 3.30 ± 0.20 | 609.6 ± 3.0 |

| LH15FE | 12.0 | 4.0 | 11.80 ± 0.25 | 4.20 ± 0.40 | 381.0 ± 3.0 |

| NH15FE | 17.0 | 4.0 | 16.80 ± 0.50 | 4.20 ± 0.40 | 381.0 ± 3.0 |

| ED24FE | 12.7 | 4.8 | 12.50 ± 0.25 | 5.00 ± 0.40 | 609.6 ± 3.0 |

| FD24FE | 15.9 | 4.8 | 15.70 ± 0.50 | 5.00 ± 0.40 | 609.6 ± 3.0 |

| GD24FE | 19.1 | 4.8 | 18.80 ± 0.50 | 5.00 ± 0.40 | 609.6 ± 3.0 |

| HD24FE | 25.4 | 4.8 | 25.00 ± 0.50 | 5.00 ± 0.40 | 609.6 ± 3.0 |

Explore Related Content

/ Press Release

04/2023

W. L. Gore & Associates, Inc. (“Gore”), a global materials science company, continues to build...

/ Press Release

04/2022

W.L. Gore & Associates, Inc. continues to build on its growing portfolio of protein capture...

/ Event

07/2024

We are thrilled to announce our participation in this year’s ADLM Conference in Chicago. This is...

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 328 4623

Have questions or unique requirements?

Our experts are here to guide you.