GORE-FLIGHT® Microwave Assemblies, 6 Series for Civil Aircraft

Gore's flexible airframe assemblies are a fit-and-forget solution proven to deliver the lowest insertion loss before/after installation in commercial aircraft. Our lightweight, yet rugged assemblies improve all aspects of protection and performance in critical avionics for longer system life, reduced downtime and total cost of ownership.

Contact Us

United States

+1 866 271 5954

Germany

+49 9144 6010

+49 9144 6816 (fax)

UK

+44 1382 56 1511

+44 1382 56 1007 (fax)

Italy

+39 045 6209 209

+39 045 6209 165 (fax)

France

+33 1 5695 6565

+33 1 5695 6401 (fax)

Spain

+34 93 480 6900

+34 93 373 7850 (fax)

Sweden

+46 31 7067800

+46 31 864226 (fax)

China (Beijing)

+86 10 5707 4999

+86 10 5707 4900 (fax)

China (Shanghai)

+86 21 5172 8299

+86 21 6247 9199 (fax)

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Japan

+81 3 6746 2582

+81 3 6746 2571 (fax)

Overview

Maintaining signal integrity under difficult aerospace environments is essential to the reliability of sophisticated avionics in commercial aircraft. Starting with installation and continuing through harsh flight conditions, like rapid temperature/pressure changes and potential contamination from fuels, oils, and fluids. At the same time, airframe assemblies must be both lightweight and durable to improve fuel efficiency and reduce operating costs.

In fact, we conducted independent studies and research showing that globally more than 75% of microwave/RF assemblies are frequently replaced because of damage during installation or operation. So, costs can quickly add up with replacing assemblies, extra labor, and more maintenance and downtime!

LIGHTWEIGHT SOLUTION WITH LOWEST INSERTION LOSS

GORE-FLIGHT Microwave Assemblies, 6 Series is proven to deliver the lowest insertion loss and more reliable VSWR before/after installation, providing stable and accurate performance compared to alternative airframe assemblies. Our rugged yet flexible airframe assemblies can easily withstand rigorous routing, maintenance activities, and flight conditions ensuring life-of-aircraft performance. They’re also 17% lighter weight compared to alternative designs, which improves fuel efficiency and increases cargo.

With this high level of performance, our 6 Series reduces costly production delays, field service frequency, and the need for purchasing replacement assemblies.

Commercial aircraft manufacturers no longer have to accept the practice of replacing microwave assemblies because they get damaged during installation. A fit-and-forget philosophy is now a reality because our 6 Series provides the most cost-effective, lightweight solution that ensures avionics performance for flight crews.

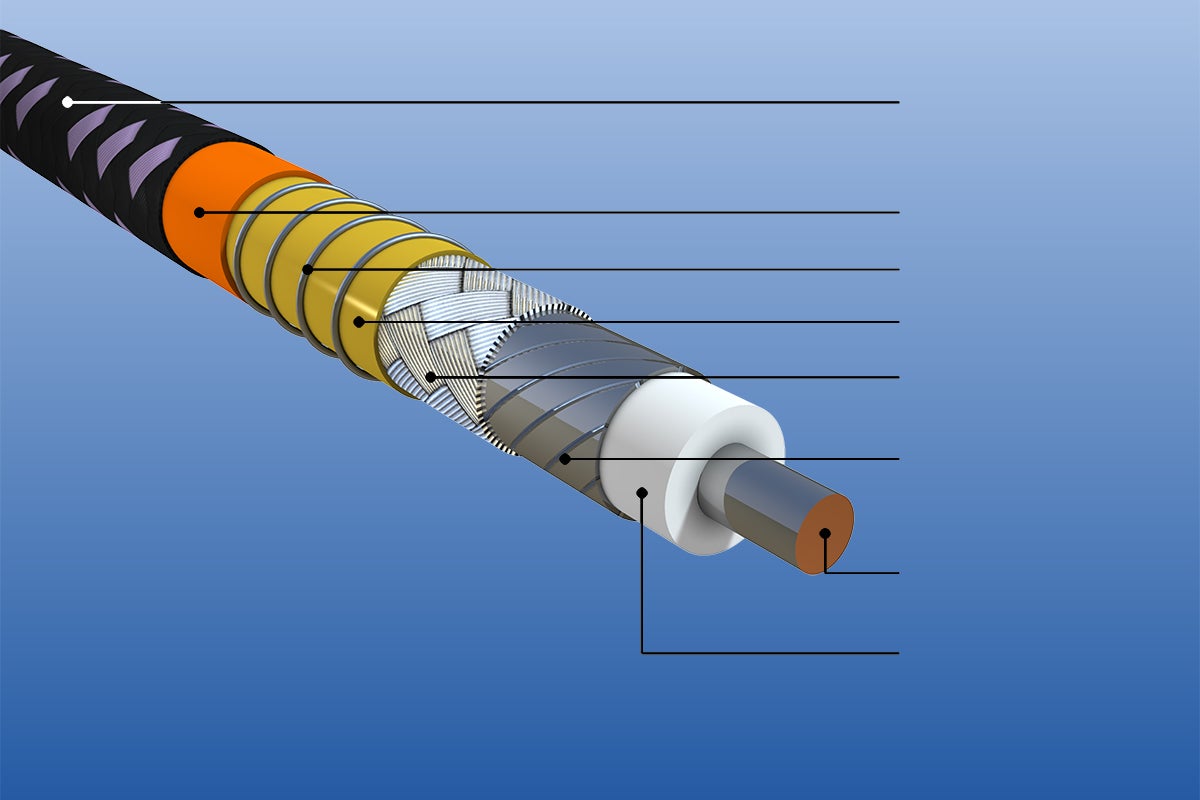

Rugged construction of GORE-FLIGHT Microwave Assemblies, 6 Series

Applications

GORE-FLIGHT Microwave Assemblies, 6 Series is engineered to perform reliably in commercial airborne applications, including:

- Ku-Band SATCOM antennas

- navigation / communications systems

- radar interconnects

If you have any questions or to discuss your specific application needs, please contact a Gore representative.

Benefits

GORE-FLIGHT Microwave Assemblies, 6 Series provides system architects and engineers with many benefits that improve electrical and mechanical performance such as:

- outstanding signal integrity in demanding aerospace environments during use and over time

- lowest insertion loss and more reliable VSWR before/after installation

- less interference among critical systems due to superior shielding effectiveness

- lower installation costs due to fewer failures and reduced aircraft production delays

- longer system life and reduced downtime with mechanically-rugged constructions

- durable vapor sealing prevents ingress of aircraft contaminants

- improved fuel efficiency and increased cargo with lightweight assembly

- increased design flexibility with robust, low-profile connector options

- proven performance with approved aerospace materials through qualification testing

For more information about the benefits of our assemblies, please contact a Gore representative.

Properties

These values demonstrate the electrical, mechanical and environmental performance of GORE-FLIGHT Microwave Assemblies, 6 Series.

Download the catalog/data sheet for more technical information, including qualifications, comparison test data, connector options, and ordering information.

| Electrical Property | Cable Type | |

|---|---|---|

| 6E | 65 | |

| Maximum Frequency Range (GHz) | 18 | |

| Typical VSWR through Max Frequency (Straight Connector) |

1.25:1 |

|

| Guaranteed VSWR through Max Frequency (Straight Connector) |

1.40:1 |

|

| Typical Insertion Loss (dB/m [dB/ft]) | 0.65 (0.20) | 1.12 (0.34) |

| Installed Insertion Loss (dB/m [dB/ft])a | 0.72 (0.22) | 1.16 (0.35) |

| Standard Impendance (Ohms) | 50 ± 1 | |

| Velocity of Propagation (Nominal) (%) | 86 | |

| Time Delay (Nominal) (ns/m [ns/ft]) | 4.0 (0.10) | |

| Capacitance (pF/m [pF/ft]) | 78.7 (24.0) | 75.8 (23.1) |

| Shielding Effectiveness (dB through Max Frequency) | 90 | |

| Dielectric Constant (Nominal) | 1.35 | |

a Based on a 10-foot assembly after 3 cycles through the installation simulator.

| Mechanical / Environemtnal Property | Cable Type | ||

|---|---|---|---|

| 6E | 65 | ||

| Jacket Material | Engineered Fluoropolymer | ||

| Jacket Color | Black and Purple | ||

| Center Conductor | Solid, Silver Plated Copper | ||

| Dielectric Material | ePTFE | ||

| Nominal Outer Diameter (mm [in]) | 8.9 (0.35) | 6.1 (0.24) | |

| Nominal Weight (g/m [lbs/1000 ft]) | 125.0 (84.0) | 60.0 (40.3) | |

| Minimum Bend Radius (mm [in]) | 48.3 (1.9) | 25.4 (1.0) | |

| Concentrated Load per MIL-T-81490, 4.7.18 (lbs) | > 150 | ||

| Temperature Range (°C)a | -55 to +125 | ||

Installation Simulator

Gore has long been a proponent of showing accurately how its products and technologies function in real-world environments before bringing them to market. Because nearly one-third of cable failures occur during installation, this is a crucial risk factor that shouldn't be minimized. Damaged airframe assemblies can lead to compromised signal integrity and failures over time, as well as additional testing, maintenance and replacement costs. With our Cable Installation Simulator, civil and military aircraft manufacturers can be confident they are getting a reliable cable assembly solution that withstands the rigors of installation and reduces the total cost of ownership.

Jim Foreman, Product Specialist

"Aircraft manufacturers need reliable solutions that can be installed deep within an aircraft and left there for the life of the platform. Therefore, we want to create 'fit-and-forget' solutions that will survive the demanding environments within an aircraft," said Jim Foreman, Product Manager at Gore. "We're committed to designing next-generation products that solve key challenges, and mitigate risk for aircraft," said Paul Pino, Lead Principal Design Engineer at Gore. "To do this, we test and simulate real-world conditions to ensure that our products do what we say they will do, consistently and reliably even in harsh conditions."

For more information about our Installation Simulator, download the white paper,

Proving Installed Performance of Airframe Microwave Assemblies.

Also, download the white paper, Reducing Life Cycle Costs with Reliable Airframe Microwave Assemblies.

Videos

Watch this video and more on YouTube of Gore engineers demonstrating the benefits of GORE Microwave/RF Assemblies.

Online Tools

Easy to Use, Fast Results

Gore’s online resources are designed specifically to make it easy for you to select the right microwave/RF assembly for your specific application requirements.

NEW Microwave/RF Cable Assembly Builder allows you to design a Microwave/RF Cable Assembly with ease from your desktop, tablet or mobile phone. Whether you are working in Test & Measurement, Spaceflight, Aerospace or Defense you can design an RF cable assembly to meet your specific needs. Once you design your assemblies you’ll be able to download custom datasheets for your builds within minutes, and you can also submit the builds for a quote. A Gore specialist will then review your designs and application requirements.

Microwave/RF Cable Assembly Calculator allows you to calculate insertion loss, VSWR and other parameters of Gore’s assemblies for different cable types. Select and compare up to 3 cables at a time.

If you have questions about our assemblies and want to discuss your specific application needs, please contact a Gore representative.

Resources

Catalog & Data Sheets: GORE® Microwave/RF Assemblies for Civil Aircraft

Data Sheets, 2.19 MB

Brochure: GORE® Aerospace Cables and Materials for Civil Aircraft

Brochures, 1.06 MB

View all resources for GORE-FLIGHT Microwave Assemblies, 6 Series for Civil Aircraft

Recent News

Press Release

Gore Showcases Latest Lightweight Aerospace & Defense Solutions at Paris International Air Show

Posted June 16, 2025

W. L. Gore & Associates, a global leader providing solution-oriented innovations that include future materials for aerospace, is proud to showcase its latest lightweight innovations at the Paris International Air Show, held from 16 – 22 June at Le Bourget, France.

Event

Visit Gore at AAAA to enhance mission success, survivability & safety

May 14, 2025 - May 16, 2025

Visit us at Booth 900 to experience our live demonstrations and discover how GORE® Cables and Materials enhance Army airframe and aviation systems. Reserve time now with a Gore specialist to discuss how we can help deliver solutions that support mission success, survivability and safety.

Press Release

Bae Systems Honors W. L. Gore & Associates With a ‘partner 2 Win’ Supplier of the Year Award

Posted April 25, 2025

NEWARK, Del./USA — W. L. Gore & Associates today announced it received a Supplier of the Year award from BAE Systems’ Partner 2 Win program. Gore was selected from a pool of suppliers that delivered exceptional performance and contributions to support supply chain success for BAE Systems’ Electronic Systems sector in 2024.

Press Release

W. L. Gore & Associates Recognized by Northrop Grumman with Supplier Excellence Award

Posted April 14, 2025

NEWARK, Del./USA — Northrop Grumman Corporation (NYSE:NOC) has recognized W. L. Gore & Associates as one of its top supplier partners during the company’s Supplier Excellence Awards.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Contact Us

Related Products

Cables & Cable Assemblies

- Microwave/RF Assemblies for Civil Aircraft

- Microwave/RF Assemblies, 7 Series for Civil Aircraft

- Ethernet Cables for Civil Aircraft

- Shielded Twisted Pair Cables for Civil Aircraft

- Fiber Optic Cables for Civil Aircraft

- USB Cables for Civil Aircraft

- HDMI Cables for Civil Aircraft

- Quad Cables for Civil Aircraft

- Fibre Channel Cables for Civil Aircraft

Sealants

Follow GORE-FLIGHT® Microwave Assemblies, 6 Series for Civil Aircraft