GORE® Acoustic Vents

Grounded in a deep understanding of acoustic science and reinforced by years of experience in material sets and capabilities research, GORE® Acoustic Vents provide proven protection against particulate and liquid contamination, and water immersion without compromising acoustic performance.

Contact Us

United States

+1 866 348 4673

Australia

+61 2 9473 6800

Benelux

+49 89 4612 2211

China

+86 21 5172 8299

France

+33 1 5695 6565

Germany

+49 89 4612 2211

India

+91 22 6768 7000

Italy

+39 045 6209 240

Japan

+81 3 6746 2572

Korea

+82 2 393 3411

Mexico

+52 81 8288 1281

Scandinavia

+46 31 706 7800

Singapore

+65 6733 2882

South America

+55 11 5502 7800

Spain

+34 93 480 6900

Taiwan

+886 2 2173 7799

United Kingdom

+44 1506 460123

Overview

Acoustic science is at the heart of Gore’s competitive advantage–with significant investments in new technologies, advanced equipment, unique testing methods, modeling services and a dedicated team of specialists–all geared to deliver products of uncompromising quality that meet our customers’ expectations and are fit for their intended end use.

Our dedication to solutions-driven products, backed by decades of experience in material sets and capabilities research, has put GORE® Acoustic Vents at the forefront of innovation, allowing us to deliver unparalleled liquid and particulate protection while maintaining exceptional levels of acoustic performance and consistency.

Each venting solution is precision engineered to achieve the highest Ingress Protection (IP) standards while balancing the trade-offs of acoustic loss. Our scientists and engineers have even developed additional protocols to better reflect real-world conditions and ensure industry-leading performance, durability and reliability… even after exposure to water.

Applications for Acoustic Vents

With over a decade of experience and designs in thousands of portable electronics devices, Gore is uniquely qualified to provide and develop optimal venting solutions for a variety of applications.

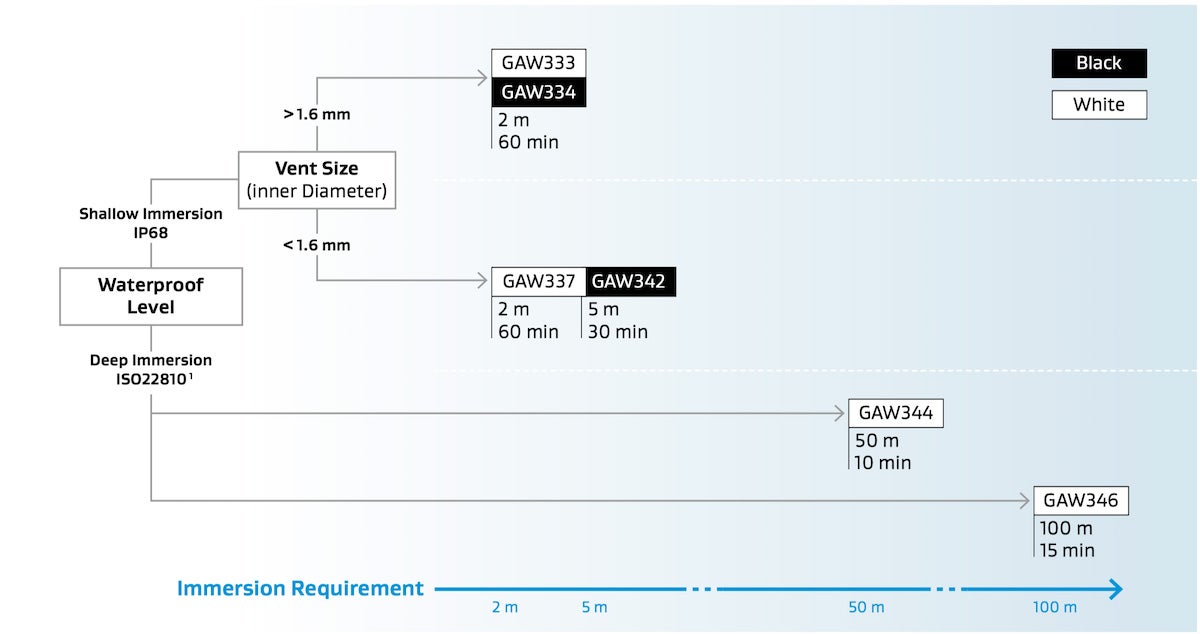

GORE® Acoustic Vents for Immersion Protection

Ideal for portable electronic devices exposed to water challenges, including immersion, that require good sound transparency and acoustic performance.

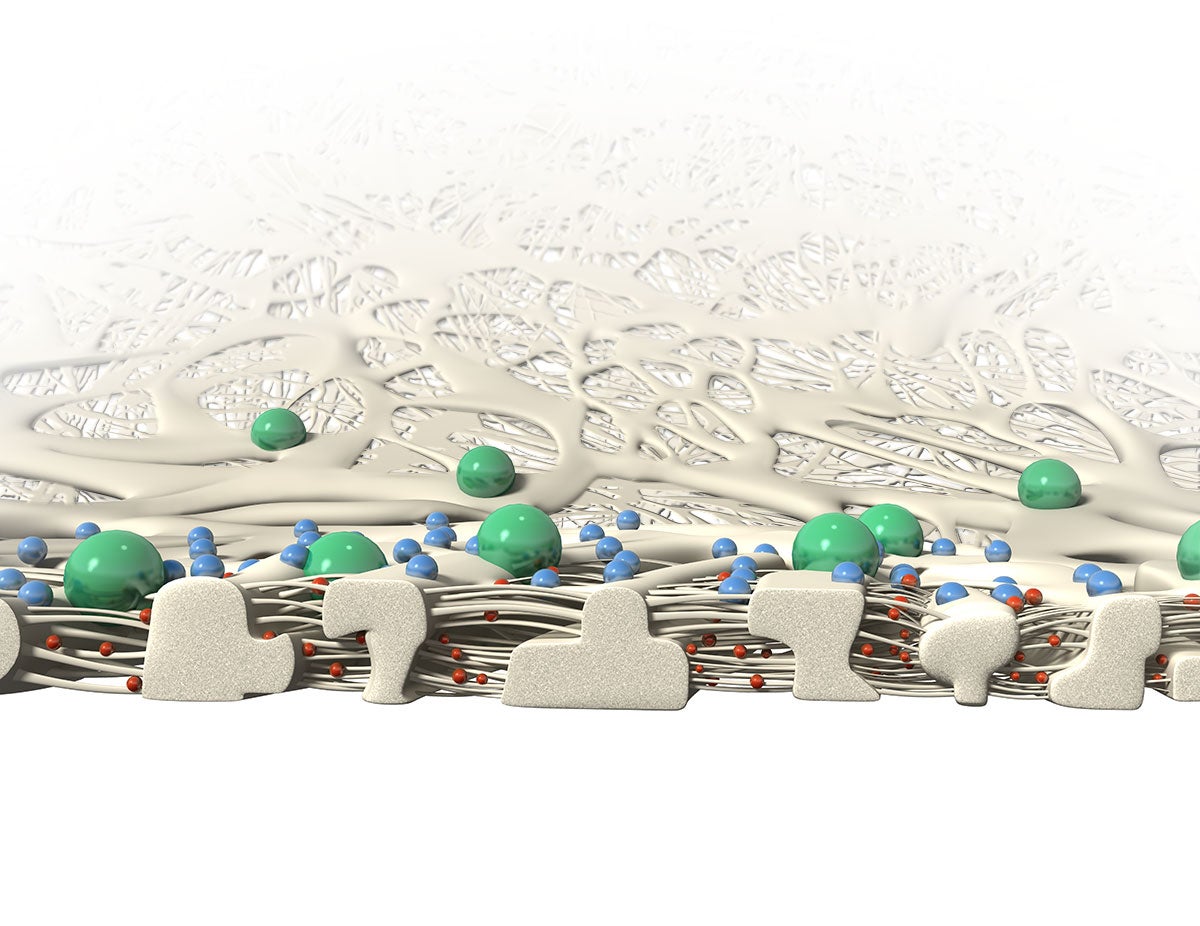

Today's consumers increasingly demand immersion-resistant handsets, wearables and other mobile electronic devices. Normally, reliable water resistance involves a trade-off in audio quality, however, GORE® Acoustic Vents for Immersion Applications facilitate optimal acoustic performance while effectively repelling water, other fluids and particulates.

Our venting solutions are engineered to repel water, sweat, cleaning solutions and low surface tension liquids like detergent and oils without sacrificing acoustic performance. Smartphones can be protected from water as deep as 5 meters for as long as 30 minutes and wearables as deep as 100 meters for 15 minutes.

One of Gore’s basic principles is to ensure our products are engineered to meet or exceed the needs of our customers’ specific applications, a concept we refer to as “fitness for use”. All our vents are subjected to rigorous material qualification and testing–including measuring transmission loss, our Extended Water Entry Pressure (eWEP) test and many other protocols that go above and beyond IP standards.

GORE® Acoustic Vents for Dust and Splash Protection

Ideal for portable electronic devices that need to stand up to dust and splash hazards that require good sound transparency and acoustic performance–rated up to IP6x:

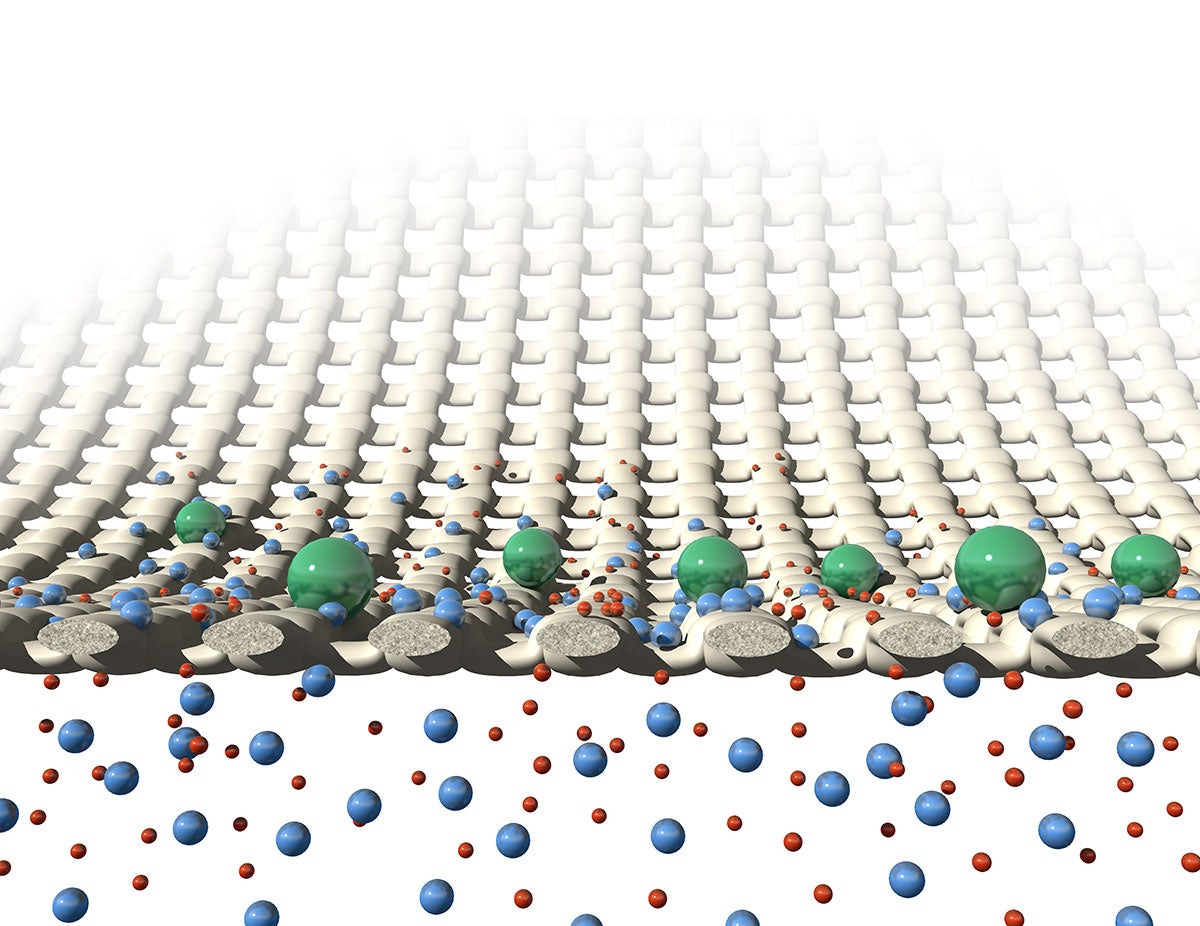

In audio devices with woven vent material, metal particles can be drawn in by, and settle on top of, the speaker magnet. As these particles accumulate, their increasing mass and weight inhibits the diaphragm from producing high levels of sound pressure.

GORE® Acoustic Vents for Dust and Splash Applications use non-woven membrane materials with a three-dimensional tortuous path structure. This allows them to effectively capture particles of varied shapes and sizes while protecting against acoustic degradation, enhancing both speaker longevity and device reliability.

For devices designed to have openings near the transducers, our engineers have also developed a rigorous “moving showerhead” test designed to increase the likelihood of water directly splashing on device openings–as would happen under real-world conditions. Using these Gore protocols, we can predict how well devices will be protected against splash hazards with greater accuracy. In addition, they allow us to evaluate potential housing solutions during the development process, before the device has been completed and assembled.

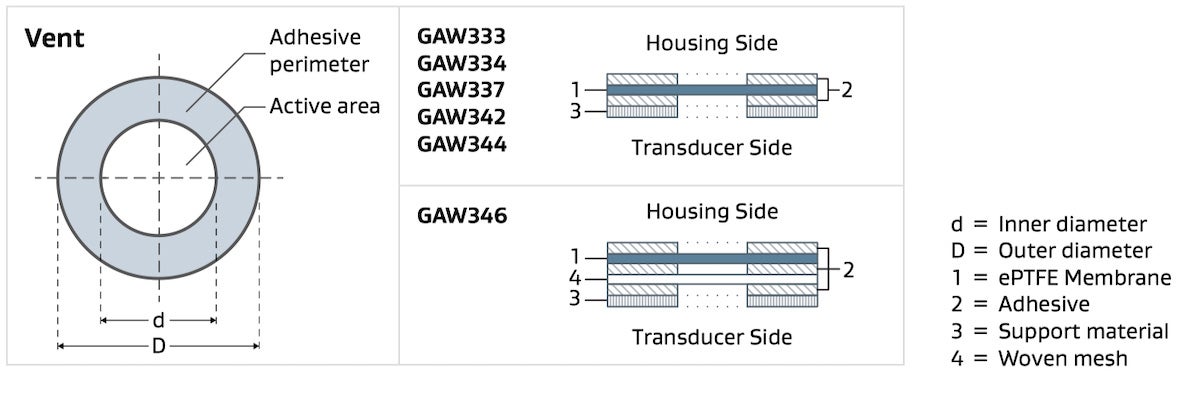

GORE® Acoustic Vents Selection General Guidelines

Gore ensures all aspects of our vents are optimized to meet the specific requirements of each customer application, from water resistance level to acoustic performance to geometries.

1 In compliance with ISO22810:2010(E) test method 4.3.2 Water resistance to overpressure.

GORE® Acoustic Vents for Immersion

|

Characteristics/ |

Series |

Series |

Series |

Series |

Series |

Series |

|---|---|---|---|---|---|---|

|

Application |

Shallow Immersion |

Deep Immersion |

||||

|

IP Rating |

IP68 ( 2m water @ 1 hr ) |

IP68 ( 5m water @ 30 min ) |

- |

|||

|

ISO Rating6 |

N/A |

50m water |

100m water |

|||

|

Insertion Loss |

< 1.3 dB (I.D. 1.6 mm) |

< 1.3 dB (I.D. 1.6 mm) |

< 1.8 dB (I.D. 1.6 mm) |

< 1.3 dB (I.D. 1.6 mm) |

< 4 dB (I.D. 1.6 mm) |

< 4 dB (I.D. 2.0 mm) |

|

Membrane Characteristic |

Hydrophobic |

Oleophobic |

||||

|

Membrane Color |

White |

Black |

White |

|||

|

Membrane Type |

ePTFE |

|||||

|

Support Material |

PET |

|||||

|

Adhesive Type |

Acrylic |

|||||

|

RoHS5 |

meets threshold requirements |

|||||

1 IP ratings for assembled devices depend on the design of the product housing.

2 Part I.D. 1.6 mm / O.D. 3.8 mm with back pressure on captive ring.

3 Part I.D. 2.0mm/O.D. 4.2mm with back pressure on captive ring.

4 Average value tested using a typical MEMS microphone system. Design of the device will affect final performance.

5 To the best of our knowledge, the parts listed above do not have any restricted substances above the maximum concentration values listed in RoHS Directive 2011/65/EU.

6 In compliance with ISO22810:2010(E) test method 4.3.2 Water resistance to overpressure. This information is based on our current level of knowledge and does not constitute a representation or warranty beyond those contained in our standard terms and conditions.

GORE® Acoustic Vents for Dust and Splash

We offer a range of standard vents for you to choose from:

|

Characteristics/ Performance |

||

|

Series GAW 111 |

Series GAW 112 |

|

|

IP rating (IED 529, 2nd)a |

IP4x |

IP4x, IP6x |

|

Comparative water spray efficiencyb |

60% |

75% |

|

Average acoustic impedance |

45 rayls MKS |

105 rayls MKS |

|

Maximum transmission loss |

< 1 dB |

< 2 dB |

|

Material type & color |

Cellulose/PET-Nonwoven & dark gray |

|

|

Membrane characteristic |

Oleophobic |

|

|

Reference thicknessc |

0.18 mm |

0.24 mm |

|

Recommended part orientation |

Mount on interior of housing |

|

|

Adhesive temperature range |

-40 °C to 70 °C |

|

|

Adhesive type |

Acrylic |

|

|

RoHSd |

Meets threshold requirements |

|

a IP ratings depend on the design of the product housing.

b Per Gore Water Spray-001: Direct stream at 70ml/min at 10psi; 0% efficiency represents open condition.

c Nominal aggregate thickness of adhesive and PET nonwoven layers. Actual thickness may vary due to the compressibility of materials.

d To the best of our knowledge, the parts listed above do not have any restricted substances above the maximum concentration values listed in RoHS Directive 2011/65/EU. This information is based on our current level of knowledge and does not constitute a representation or warranty beyond those contained in our standard terms and conditions.

Standard Parts

Transducer Type: Microphone

Dimension (mm) | Part Number | |||||||

|---|---|---|---|---|---|---|---|---|

Inner | Outer | Reference | Series | Series | Series | Series | Series | Series |

1.4 | 3.0 | 0.36 | - | - | GAW3371.43.0 | GAW3421.43.0 | - | - |

1.6 | 3.2 | 0.31 | GAW3331.63.2 | GAW3341.63.2 | - | GAW3421.63.2 | - | - |

1.6 | 3.8 | 0.31 | - | - | - | - | GAW3441.63.8 | - |

1.6 | 4.2 | 0.28 | - | - | - | - | - | - |

2.0 | 3.6 | 0.31 | GAW3332.03.6 | GAW3342.03.6 | - | GAW3422.03.6 | - | - |

2.0 | 4.2 | 0.31 | - | - | - | - | GAW3442.04.2 | - |

2.0 | 4.2 | 0.40 | - | - | - | - | - | GAW3462.04.2 |

2.4 | 5.0 | 0.31 | - | GAW3342.45.0 | - | - | - | - |

3.0 | 6.0 | 0.31 | - | GAW3343.06.0 | - | - | - | - |

4.0 | 8.0 | 0.31 | - | GAW3344.08.0 | - | - | - | - |

5.0 | 9.4 | 0.31 | - | GAW3345.09.4 | - | - | - | - |

2x2 | 4x4 | 0.31 | - | GAW3342.04.0R | - | - | - | - |

* Nominal aggregate thickness of all layers (adhesive/membrane/support material) of finished part. Actual thickness may vary due to construction of finished part and compressibility of materials.

Design Considerations

Predicting the conditions your product will encounter can be difficult, so our application engineers are on hand to assist in selecting the right solution for your specific application requirements–ensuring the selected solution meets the protection requirement while still providing the best acoustic performance.

Factors that might be considered include:

- What is the minimum requirement for acoustic consistency?

- What is the maximum level of transmission loss allowable?

- How will the product be used?

- What is the required frequency range?

- What are the required liquid, particulate and contaminant protection levels?

- Will your device need protection against water immersion?

- What shape, size and thickness of the vent is required?

- How much space is available within your device enclosure? Will there be an open cavity?

- What surface will the vent be mounted on and what type of adhesive is required?

- What are the minimum and maximum temperatures your device may face?

- Will vents be mounted by hand or by pick and place machine?

RELIABLE INSTALLATION

Integrating portable vents with your products can be a technical nightmare since all the requirements make installation costly and time consuming. Gore drives down development time with easy and reliable vent installation all backed by the fact we currently support over 1 billion installations globally. Please see below for our product installation manuals and videos:

Installation and Handling Guidelines for Portable Electronic Vents

Installation Guides,

Why Choose GORE® Portable Electronic Vents for Your Electronic Devices?

Leading OEMs have purchased over 10 billion of GORE® Portable Electronic Vents because they know our products and services can help accelerate their development of innovative and differentiated devices in fast-paced, highly competitive markets.

Product & Application Leadership

Grounded in a deep understanding of material science and acoustics, Gore can provide the optimum venting solution. We balance trade-offs between diverse problems such as adverse operating environments, immersion events and acoustic performance.

Reliable Performance

To ensure products are “fit for use”, every Gore product must adhere to the highest standards of quality, performance and reliability. Through a comprehensive understanding of end-use applications and requirements, our products do what they say they will do.

Fast Development

The mobile electronics industry develops and releases new products quickly. Our fast response to customer requests during the development process sets us apart. Gore supports this need for quickness with designs and prototypes to ensure engineering teams can meet their project timelines and their application requirements.

Supply Security

Leading OEMS specify Gore because we have consistently proven our ability to quickly ramp up to supply vents for projects of over 10 million devices per year and to continue to supply high quality products on-time without disruption.

Material Science

Gore is a global materials science company dedicated to transforming industries and improving lives. Gore develops materials with microporous structures that provide desirable attributes and performance characteristics to engineer vents and other products used in a variety of markets and industries.

Global Support

Our global teams of sales associates, application engineers, manufacturing engineers, and research personnel enable us to provide agile and robust support to customers around the world.

Case Studies

Read about how the GORE® Portable Electronic Vents team of engineers and scientists are working with customers to ensure delivery of the best possible venting, production and customized solutions:

Resource Library

Get all the media and documentation available for GORE® Portable Electronic Vents:

Designing an Acoustic System with GORE® Acoustic Vents

Technical Information

How to Select an Acoustic Vent?

Product Selection Guides,

Extended Water Entry Pressure Test Guideline

Technical Information,

Recent News

Gore launches two breakthrough products that enable smartwatch users to dive down to 100 meters. Read all about our advanced GORE® Acoustic Vent and GORE® Pressure Vent in our 10 ATM flyer or learn more on this website.

Event

Discover the world of Gore at IEEE SENSORS 2023 in Vienna, Austria!

October 29, 2023 - November 1, 2023

Join us at IEEE SENSORS 2023, a renowned event in the field of sensor technology and innovation. We are excited to announce that W. L. Gore & Associates GmbH will be unveiling cutting-edge solutions at booth #14 during the conference, taking place in Vienna, Austria from October 29 to November 01, 2023.

Event

Visit Gore at MEMS & Imaging Sensors Summit in Grenoble (France)

September 19, 2023 - September 21, 2023

Join us at the highly anticipated MEMS & Imaging Sensors Summit, a premier event in field of sensor technology and innovation. We are excited to announce that our company will be showcasing our latest cutting-edge solutions at booth #19 during the summit, held in the picturesque city of Grenoble, France from September 19 to 21, 2023.

As one of the event sponsors we invite you to stop by any time to meet with our team at the MEMS & Sensor Technical Congress in Massachusetts, from May 23 to 24, 2023.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Contact Us

Follow Gore Vents

Related Products

Venting