GORE® SKYFLEX® Aerospace Materials

Backed by decades of successful applications, our tapes and gaskets are proven to solve many sealing and surface protection challenges in defense and civil aircraft. Leading OEMs routinely specify our dry, lightweight aircraft sealants and materials because they simplify installation, increase throughput, improve safety and reduce lifecycle costs.

Contact Us

+1 800 224 2670

Overview

Reliable Sealing & Surface Protection

Aviation sealants can significantly impact aircraft availability, maintainability and overall costs. For example, traditional two-component materials, like a liquid polysulfide polymer sealant, involve extra process steps and may weaken and break down from mechanical forces and environmental factors. Standard spray-on aerospace coatings don’t necessarily provide adequate surface protection on airframe structures either. But Gore’s dry, lightweight aerospace materials and material technologies are proven more reliable while also quicker and easier to install.

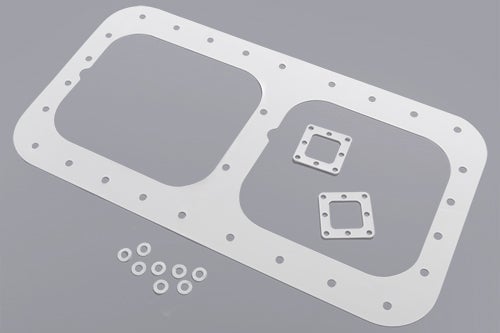

GORE SKYFLEX Aerospace Materials are protective films that effectively seal panels and protect surfaces from mechanical forces and harsh contaminants that can severely damage aircraft and helicopter structures. Unlike traditional light-cure materials for aerospace, our tapes and gaskets don’t require any cure time, which reduces installation steps and simplifies the process.

Why use aircraft sealing that is time-consuming, labor-intensive, delays production and maintenance schedules, and costs more overall? Optimize your aircraft or helicopter production and maintenance using our materials that provide reliable surface and sealing protection, increase availability and throughput, and reduce lifecycle costs.

Tapes & Gaskets

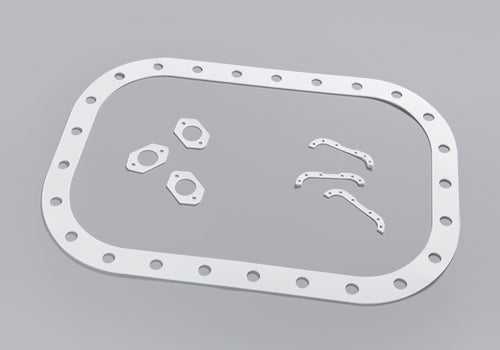

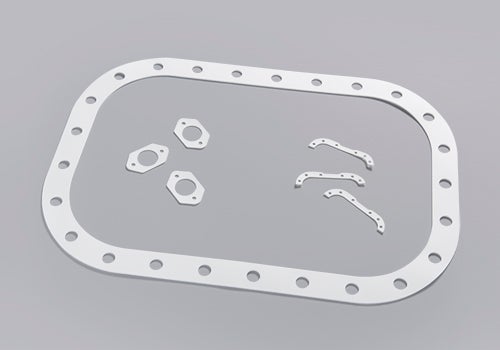

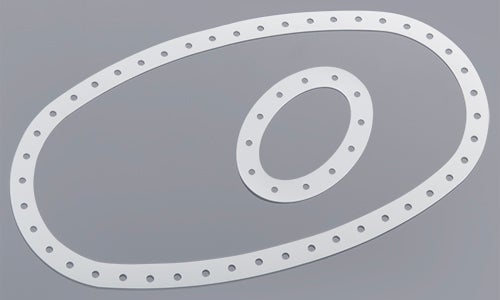

Our aviation-approved materials for multiple defense and commercial aircraft are often used instead of form-in-place (FIP) wet seals. They’re available in a variety of FIP dry tapes and die-cut gaskets in various forms and sizes. Start by reviewing our portfolio below for your particular aircraft sealant application.

Then, download our data sheet for specific widths, thicknesses, gap-filling compensation ranges, operating temperatures and more. If you have any questions or need help selecting the right series of our tapes or gaskets, contact us today.

GORE SKYFLEX Aerospace Tapes

GORE SKYFLEX Aerospace Gaskets

Dry vs. Wet Sealants

Compare GORE SKYFLEX Aerospace Materials against other dry tapes and wet sealants to better understand how each sealant performs in specific environments.

We also invite you to read our article on improving aircraft availability with alternative FIP sealants.

| Purpose | Gore’s Tapes & Gaskets | Polysulfide Wet Seals | Polyurethane Tapes | Standard PTFE Tapes | Gel Tapes |

|---|---|---|---|---|---|

| Surface Protection | ✅ | ⚠️ | ✅ | ✅ | ⚠️ |

| Environmental Sealing | ✅ | ✅ | 🚫 | 🚫 | ✅ |

| Wide Temperature Range | ✅ | ✅ | 🚫 | ✅ | ✅ |

| Highly Conformable/ Gap Filling |

✅ | ✅ | 🚫 | 🚫 | ✅ |

| Stays under Compression/ No Squeeze Out |

✅ | 🚫 | ✅ | ✅ | 🚫 |

| Non-Curing | ✅ | 🚫 | ✅ | ✅ | ✅ |

| Easier/Faster Installation | ✅ | 🚫 | ✅ | ✅ | ✅ |

| Reusable Seals | ✅ | 🚫 | 🚫 | ⚠️ | 🚫 |

| Non-Hazardous | ✅ | 🚫 | ✅ | ✅ | ✅ |

| Improved Safety | ✅ | 🚫 | ✅ | ✅ | ✅ |

| No Special Equipment/PPE | ✅ | 🚫 | ✅ | ✅ | ✅ |

Features & Benefits

Unlike low-temperature cure materials for aircraft, GORE SKYFLEX Aerospace Materials are manufactured with unique features that make them more durable against challenging environmental factors and aircraft conditions, including:

- chemically inert, non-hazardous materials

- temperature- and abrasion-resistant materials

- dry, lightweight, highly conformable materials

- available in a variety of material sets, forms and sizes

For design engineers, material handling installers or mechanics, our tapes and gaskets provide many benefits that simplify aircraft assembly, increase availability and throughput, and reduce lifecycle costs, like:

- reliable, predictable sealing/surface protection and gap-filling

- proven resistance against mechanical forces, wide temps, chemicals, fuels and more

- easier, quicker installation with fewer process steps and no cure time

- less replacements, rework and lifecycle costs with reusable seals

- no operator certification, training or special material handling required

- low environmental impact and improved safety with non-hazardous materials

Applications & Guides

As one of the industry’s foremost aerospace materials suppliers, we thoroughly test GORE SKYFLEX Aerospace Materials to meet many strict requirements, like SAE AMS3255.

They’re routinely specified by leading aircraft OEMs because of their proven reliable performance for decades in a variety of applications, like:

- access panels (wing, fuel, LE/TE & dry bay)

- floorboards & structures (cargo seal & passenger area seal)

- engine cowlings

- external fuel tank sealer

- fairings

- fuel bladder cavities

- helicopter tail boom covers

- wing D-Noses

- lighting assemblies

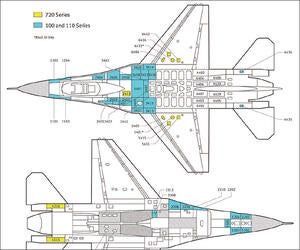

Our materials are approved for use on many fixed-wing and rotary-wing aircraft from OEMs like Airbus, Boeing, Bombardier, Comac and Embraer. Below are Technical Order (T.O.) approvals when using our materials in aircraft as military aerospace seals.

- A-10

- B-1B

- B-52

- C-5

- C-17

- C-130

- E-3

- EA-6B

- E-6

- F-5

- F-15

- F-16

- F-35

- H-53

- KC-135

- T-45

- V-22

Download our application guides providing examples using our tapes and gaskets, specific T.O. approvals, material requirements and locations for installing our materials in military aircraft.

Installation & Maintenance

Wet process installation involves extra time-consuming and labor-intensive steps that can make it difficult to meet production targets, maintenance schedules and budgets. But applying aircraft sealant is much easier and faster using GORE SKYFLEX Aerospace Materials.

Our tapes and gaskets eliminate process steps because there’s no mixing, masking, curing or re-assembling panels. There’s also no special handling required, cleanup after installation or hazardous waste disposal. They’re reusable and compliant over multiple open/close cycles, meaning you can easily remove aircraft panels during inspection without replacing or reworking our materials — unlike an epoxy polysulfide sealant.

Download our step-by-step aircraft sealant and gasket installation guides. You can also watch videos for installing, removing or repairing our materials based on our aircraft sealing methods.

Installation Guides

Instructional Videos

| Application/Purpose | Environmental Sealing | Special Environmental Sealing | Surface Protection |

|---|---|---|---|

| Straight/Curved | Video | Video | — |

| Corners/Joints | Video | Video | — |

| Floorboards | Video | — | — |

| Anti-Chafe/Galvanic Isolator | — | — | Video |

| Fuel Sealing | Video | — | — |

| Gaskets | Video | — | — |

| Compilation | Video | — | — |

| Complete Installation | — | Video | — |

| Repairs/Clean Up | Video | — | — |

Our videos are available in multiple languages on YouTube. Or, call if you have any questions about installing aircraft sealants from Gore in your specific application.

Safety Information

GORE SKYFLEX Aerospace Materials are non-hazardous, improving environmental and operator safety. Our tapes and gaskets comply with global environmental regulations set forth by the Canadian Environmental Protection Act (CEPA), the European Chemicals Agency (ECHA) and the U.S. Occupational Safety and Health Administration (OSHA).

Before using our types of aircraft sealant in your application, carefully review our recommended standard practices below to reduce exposure to decomposition by-products.

How to Buy

For several decades, our materials have reliably protected defense and civil aircraft structures, which is why leading OEMs continue to specify them. They’re approved for use on many aircraft that use polymers in aerospace applications. We offer an assortment of dry, lightweight tapes and die-cut gaskets in various forms and sizes to accommodate many applications.

If you’re ready to buy our materials, contact us or an authorized distributor today. For military aircraft, view our part numbers with corresponding National Stock Numbers (NSNs) that can also be ordered through U.S. Defense Logistics Agency channels.

Alternatively, we can work closely with you to evaluate the parameters of your application and recommend the appropriate tape or gasket series.

Purchase our materials through an authorized distributor.

Look up our part numbers for defense fixed-wing NSN.

Look up our part numbers for defense helicopter NSN.

Talk with a Gore representative today about your application.

Resources

Data Sheet: GORE® SKYFLEX® Aerospace Materials

Data Sheets, 1.45 MB

NSN List for Defense Aircraft: GORE® SKYFLEX® Aerospace Materials

Part Number Information, 167.07 KB

Article: Form-in-Place Seals — Improving Aircraft Availability with Alternative Sealants

Industry Articles, 491.62 KB

NSN List for Defense Helicopters: GORE® SKYFLEX® Aerospace Materials

Part Number Information, 134.81 KB

Recent News

Press Release

Gore Showcases Latest Lightweight Aerospace & Defense Solutions at Paris International Air Show

Posted June 16, 2025

W. L. Gore & Associates, a global leader providing solution-oriented innovations that include future materials for aerospace, is proud to showcase its latest lightweight innovations at the Paris International Air Show, held from 16 – 22 June at Le Bourget, France.

Event

Visit Gore at AAAA to enhance mission success, survivability & safety

May 14, 2025 - May 16, 2025

Visit us at Booth 900 to experience our live demonstrations and discover how GORE® Cables and Materials enhance Army airframe and aviation systems. Reserve time now with a Gore specialist to discuss how we can help deliver solutions that support mission success, survivability and safety.

Come by to see us in Hall 1, Booth 1120G, at this year’s airshow in Farnborough, UK, from July 22-26 to discover how GORE® Cables and Materials can help propel aerospace and defense into the future. See demos to witness firsthand how our solutions outperform many alternatives. Reserve time at the airshow now to meet with a Gore specialist and discuss your latest issues and requirements.

Visit Gore at the UK Pavilion in Hall 2, Booth FG168, to experience live demos and explore our durable cables and materials engineered for reliability in the most challenging conditions.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Follow GORE® SKYFLEX® Aerospace Materials