Reliability in Network Infrastructure

White Papers, United States

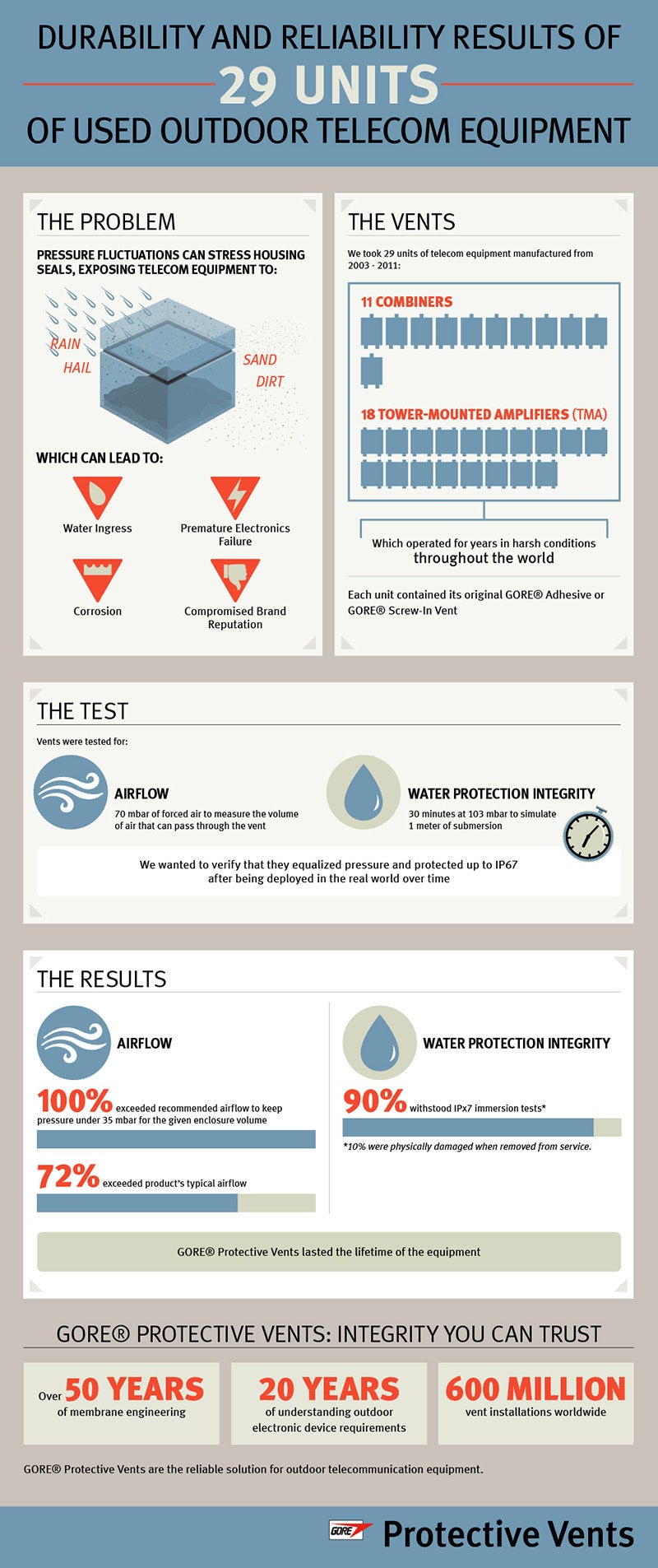

FEBRUARY 2014 // After up to 11 years in the field, 29 tower-mounted amplifiers and combiners with GORE® Vents were inspected and integrity-tested. 100% of the units exceeded recommended airflow and 90% passed the IPX7 immersion test, demonstrating the vents’ exceptional reliability.

Internal pressure fluctuations in telecommunications equipment put significant stress on the housing seals, which over time can result in compromising the seals and the equipment’s reliability. These fluctuations are most frequently caused by sudden weather and temperature changes in the outdoor environments in which the equipment must operate. Once the seals fail, contaminants such as rain, dust, and dirt can enter the housing and cause premature failure of the electronics.

GORE® Protective Vents are engineered to eliminate stress and damage on seals by allowing air to flow freely in and out of electronic housings. Based on their research on the impact of pressure differentials on sealed enclosures, W. L. Gore & Associates recommends maintaining internal pressure at or below 35 millibars (mbar). Gore’s engineering team bases its vent recommendations for each application on such variables as volume of enclosure, amount of internal free space, level of water and contaminant protection required, enclosure materials of construction, and environmental conditions in which the device will be used. By evaluating these variables, Gore is able to specify the best venting solution to reduce the impact of pressure differentials and increase the lifetime performance of telecommunication equipment.

To evaluate the performance of GORE Protective Vents after extended exposure to real-world conditions, Gore decided to test vents that had been in telecommunication equipment operating throughout the world for several years. Each vent was evaluated for water protection integrity and airflow.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.