Data Sheet: GORE® FireWire® Cables for Aircraft

Data Sheets, United States

A premier solution for copper-based IEEE 1394b FireWire data links, W. L. Gore & Associates offers a version of quadrax cables called GORE FireWire Cables for defense and commercial aircraft. Designed to withstand extreme aircraft conditions without damage over the life of the system, our durable cables transmit uninterrupted, high-fidelity signals with flexure for interconnect solutions up to 30 m (100 ft.) at S400 data transfer rates. They also feature smaller diameters that save weight in aircraft.

Cable Performance & Specifications

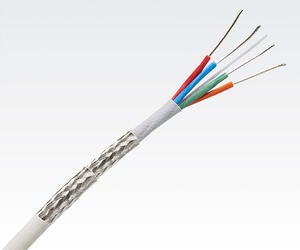

Gore's highly flexible yet durable materials provide a protective barrier that allows GORE FireWire Cables for Aircraft to withstand challenging routing, maintenance and airborne environments for long-term product life. The robust construction of our aviation cables includes the following layers:

- Outer jacket made from Gore’s engineered fluoropolymers

- Double-braided shield

- Expanded polytetrafluoroethylene (ePTFE) binder

- Color-coded composite dielectric

- Silver-plated copper or SPC alloy conductors

- Fluorinated ethylene propylene (FEP) filler

Their rugged qualities are complemented by several other advantages compared to alternative cable designs, including:

Compact, Lightweight Design

Gore's high data rate quadrax design is approximately 40% smaller than dual twisted pair constructions, making for easy routing in complex, tight systems. They’re also proven to save as much as 5.2 kg (11.5 lb.) per aircraft, delivering weight savings hard to find elsewhere.

Signal Integrity with Flexure

Using a diamond-shaped eye mask test with minimum receiver sensitivity as specified by IEEE 1394b, the eye pattern of a 15-m (50-ft.) cable transmitting 500 Mb of data was evaluated before and during flexure. Results indicated that Gore's high-speed FireWire cables passed with a margin, meaning greater transmission length is possible. The test was repeated with Gore's cable wrapped 20 times around a 12.7-mm (0.5-in.) radius mandrel with no substantial degradation in signal quality observed with flexure.

Qualified to Strict Industry Standards across Aircraft Applications

GORE FireWire Cables for Aircraft are tested and pre-qualified to ensure that they transmit uninterrupted, high-fidelity signals with flexure for interconnect solutions up to 30 m (100 ft.) at S400 data transfer rates. They meet the following industry standards:

- ABD0031 (AITM 2.0005); BSS7230; FAR Part 25, Appendix F, Part I: Flammability

- ABD0031 (AITM 3.0005); BSS7239: Toxicity

- ABD0031 (AITM 3.0008B); BSS7238; FAR Part 25, Appendix F, Part V: Smoke Density

- ANSI/NEMA WC 27500: Environmental Testing, Jacket and Marking

- SAE AS4373™: Test Methods for Insulated Electric Wire (Contact Gore for available data)

- SAE AS5643™: IEEE-1394b Interface Requirements for Military and Aerospace Vehicle Applications

- SAE AS5643™/2: S200 Copper Media Interface Characteristics Over Extended Distances

- SAE AS5643™/3: IEEE-1394 Beta PHY Enhancements

- SAE AS5657A™: Test Plan/Procedure for AS5643 IEEE-1394b Interface Requirements for Military and Aerospace Vehicle Applications (Contact Gore for available data)

Their reliability and compliance make them an optimal solution for current and next-gen avionics digital networks, flight control, high-definition streaming camera and video systems, as well as mission systems.

What's more, GORE FireWire Cables for Aircraft are designed to fit a variety of high-speed connector systems and backshells, including ARINC and MIL-STD-38999 with size 8 and 22D contacts. For exact part numbers, tooling information and termination instructions, contact the specific manufacturer, such as Amphenol® and Glenair®.

How to Order GORE FireWire Cables for Aircraft

Available in standard sizes, our FireWire cables for military and civil aircraft are available for purchase through Gore’s trusted distributors. To learn more or discuss the specifications for your exact application, contact a Gore representative today.

You can also request tested, pre-qualified, complimentary samples, which are available with short lead times based on in-stock availability and include the following part numbers:

- RCN8645

- RCN8647

- RCB8652

- RCN9204

- RCN9205

- RCN9206

Amphenol is a registered trademark of Amphenol Corporation.

FireWire is a registered trademark of Apple, Inc.

Glenair is a registered trademark of Glenair, Inc.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.