GORE® LOW DRAG Filter Bags

A step change in industrial dry filtration: An entirely new class of membranes developed by Gore acts as a true surface filter in fume and fine powder applications.

Contact Us

United States

+1 800 437 5427

Australia

+61 2 9473 6800

Canada

+1 800 437 5427

Central America

+52 81 8288 1281

China

+86 21 51728299

France

+33 (0)1 56 95 65 65

Germany/Austria/Switzerland

+ 49 89 4612 2211

India

+ 91-22-67687000

Italy

+ 39 045 620 9250

Japan

+ 81-3-6746-2572

Korea

+ 82 2 393 3411

Mexico

+52 81 8288 1281

Netherlands

+31 (0) 135 07 47 00

Scandinavia

+ 46 31 706 7800

Singapore

+ 65 6733 2882

Spain

+ 34 93 480 6900

South America

+ 55 11 5502 7800

South Africa

+ 27 11 894 2248

Taiwan

+ 886 2 8771 7799 x28731

United Arab Emirates

+971 2 4437749

United Kingdom

+ 44 1506 460123

Russia

+ 49 89 4612 2211

Overview

The new GORE LOW DRAG Filter Bag — a game changer to the industry!

GORE LOW DRAG Filter Bags — a step change in industrial dry filtration. An entirely new class of membranes developed by Gore acts as a true surface filter in fume and fine powder applications.

The GORE LOW DRAG Filter Bag balances this filter performance through the simultaneous optimization of attributes hugely important to many industries:

- Increased fan energy efficiency

- Increased flow capacity

- Increased bag life due to reduced cleaning

- Improved product capture efficiency

- Reduced emissions

These attributes enable Gore’s solutions to deliver the lowest total cost of ownership available in a filtration system.

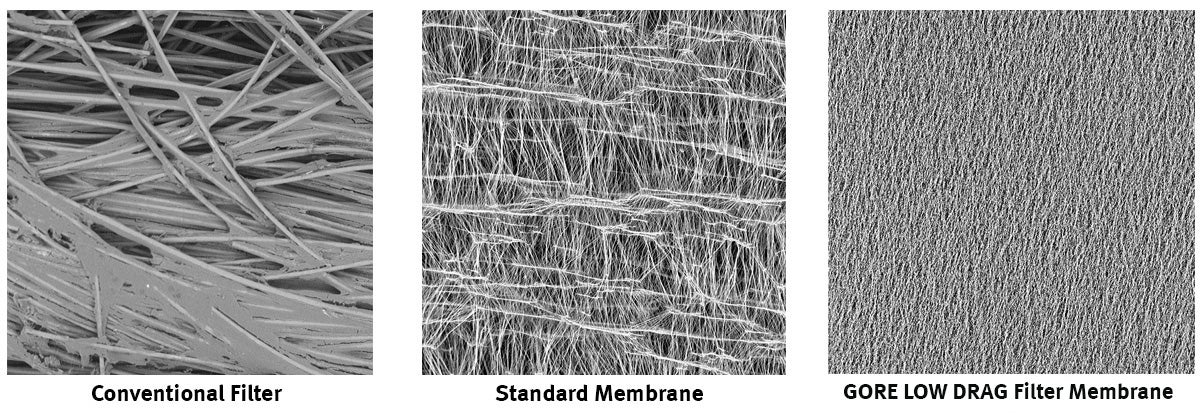

The Science Behind the Solution

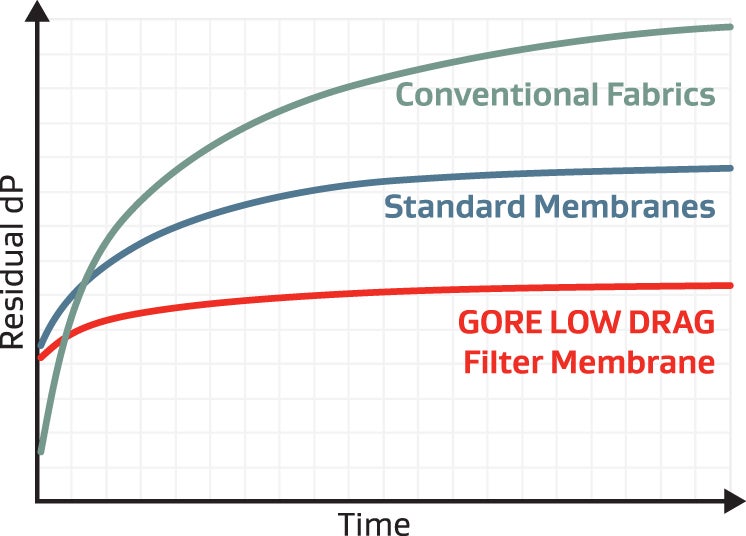

Gore’s new materials are inherently less resistant to airflow and are therefore more efficient with respect to the amount of energy required to drive air through them during filtration. The key is improved cleanability, without sacrificing durability or particle capture efficiency.

Energy savings and emission control in the Metals Industry

For years, filter resistance has been the biggest impediment to efficient meltshop evacuation in metal smelting plants resulting in negative effects on operating costs, maintenance and environmental compliance. Our fabric filter bags offer a solution that delivers increased performance and a low total cost of ownership. That’s because GORE LOW DRAG Filter Bags decrease filter resistance while achieving best in class durability, life and emissions.

Reducing Total Cost of Ownership in Steel Production

Steel plants are looking to reduce the costs associated with their air pollution control systems, while maintaining compliance in a reliable, predictable manner. With the new laminate, robust filter bag design and complete application and system optimization, steel plant operators can achieve extremely reliable and low cost of operation, maintenance and compliance.

Watch the video to learn how GORE LOW DRAG Filter Bags improve your overall operation of air pollution control systems in metallurgical processing operations. Find out how improvements such as increased airflow and efficient energy utilization allow for maximum compliant flexibility in operations such as smelting, refining, recycling and recovery.

Maximizing System performance in Ferroalloy production

Ferroalloys producers constantly look to improve their furnace operations without making major financial investments or changes to air pollution control systems. That can be a tall order for a filtration solution: Increase productivity. Increase emissions control. Don’t increase costs. GORE LOW DRAG Filter Bags achieve those requirements while lowering overall costs — making them a game-changer that only requires you to change your filters.

With GORE LOW DRAG Filter Bags’ industry leading cleanability, ferroalloys producers experience reduced pressure drop and 10–15% greater airflow — leading to greater emissions control, longer bag life and an all-around more reliable filtration solution with the lowest cost of ownership in the industry.

GORE LOW DRAG Filter Bags help you to

- maximize furnace evacuation (10 - 15% greater airflow)

- reduce operation costs (15 - 20% lower fan energy costs)

- lower emissions (80% reduction in <PM 0.5 emissions)

- achieve longer bag life (10 - 20%)

Watch this video to learn more about the benefits GORE LOW DRAG Filter Bags bring to the Ferroalloy industry.

Learn more about Gore’s filtration products for the Metals Industry.

Emission Control and increased airflow in the Cement Industry

Cement plant fabric filter baghouses can benefit from Gore’s latest innovation — GORE LOW DRAG Filter Bags — in multiple ways. Check out these scenarios:

| Scenario 1: |

Production is limited by airflow constraints through the kiln? Increase airflow and use this additional airflow for higher clinker production rates. |

| Scenario 2: |

Burning alternative fuels and limited by the amount of fuel burnt due to a shortage of available O2? Increase airflow and utilize this airflow to increase alternative fuel utilization. |

| Scenario 3: |

Can’t utilize additional airflow for production increases or alternative fuel increases? Reap the benefit of significant fan energy savings. |

| Scenario 4: |

Problem spots in the baghouse due to localized failures or abrasion? Permanently remove filter bags from these areas of the baghouse, while increasing performance. |

See how GORE LOW DRAG Filter Bags help increase your airflow and productivity while saving costs and reducing emissions. Our membrane-based filter technology ensures continuous compliance with increasing environmental regulations

Learn more about Gore’s filtration products for the Cement Industry.

Increased productivity for the Chemicals Industry

Producing as much product as possible is the primary goal of many chemical manufacturers. While all GORE® Filter Bags provide excellent product capture, GORE LOW DRAG Filter Bags can potentially increase your throughput. How?

Instead of the “seasoning” effect which causes an increase in filter resistance during the life of other dry filtration materials, GORE LOW DRAG Filter Bags maintain high airflow levels (or low baghouse differential pressure) well into their useful life. For a chemical manufacturer whose productivity is limited by the amount of airflow, which can be achieved in the baghouse, this means increased throughput.

In fact, GORE LOW DRAG Filter Bags can be utilized in a variety of ways for the benefit of chemical manufacturers. The most common benefits are

- Longer Bag Life

- Lower Emissions

- Higher Airflow (Higher Productivity)

- Lower and More Stable dP

GORE LOW DRAG Filter Bags can be optimized to reduce your total cost of ownership by decreasing the amount of energy needed to push the required air through your baghouse; or, the bags can be optimized to increase the life of your filter bags.

Learn more about Gore’s filtration products for the Chemicals Industry.

Whichever application you are interested in, be sure to give our specialists a call. We can advise the best solution for you, taking into consideration your specific requirements and our wide range of customizable solutions .

Contact our filtration experts to learn more.

Resources

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.