Industrial Fluids Filtration Solutions

GORE Membrane Filter Sock and Tube assemblies provide highly efficient ePTFE membrane filtration for use in tubular backpulse liquid filtration systems.

Contact Us

North America

+1 800 437 5427

Brazil

+55 11 5502 7800

Overview

GORE Membrane Filter Sock and Tube assemblies provide excellent filtration efficiency and economical performance in high flow rate and/or high feed solids applications due to a combination of GORE™ membrane's unique properties and extensive application and manufacturing expertise.

GORE membrane filter socks and GORE® filter tube assemblies are used in Kraft pulp mills, Chlor-Alkali plants and other process or wastewater filtration applications in chemical processing industries. GORE™ membrane filter socks have a unique microporous membrane surface that prevents particles from becoming imbedded inside the membrane structure. The membranes are available in several different micron ratings and are laminated to a polypropylene felt, a polyester felt, or a felt made with Gore fibers depending on the chemical and thermal requirements of the application.

Markets & Applications

Kraft Pulp Mills

GORE membrane filter socks are used in white liquor and lime mud wash tubular pressure filters in the pulp and paper industry.

The membranes, available in several different micron ratings, are laminated to a polypropylene felt support. An all welded construction and special EPDM O-rings are used to greatly reduce the potential for bypassing found in other sock constructions.

Benefits

- Higher throughput

- Less frequent acid washings

- Better upset recoverability

- Longer effective life

Depending on your location, GORE membrane filter socks can be purchased directly, through licensed agents or OEM's. Please contact us for more information.

Chlor-Alkali Processing

GORE® Filter Tube Assemblies and GORE® Membrane Filter Socks (available in both PP and ePTFE felts) are used to purify the brine regardless of source in the Chlor-alkali process. Purifying various process/wastewater streams in 100’s of installations worldwide, we have proven the success of our precoat-free technology in replacing a traditional three step filtration system (clarifier, sand filter, precoat filter) with a one-step filter. Our new GORE® Filter Tube Assemblies offer the additional benefits of higher surface area and improved sealing characteristics providing higher flow rates in a convenient, easy to install format.

Lithium Extraction: Eliminate sluice streams to improve overall output concentration

Gore is working to develop solutions for lithium filtration that ensure efficient lithium extraction to support a sustainable transition. Gore's tubular membrane back-pulse filters operate like a candle filter. Short filtration cycles overcome high solids build-up and sticky metal hydroxide challenges. They deliver submicron filtration for feeds anywhere from 1 ppm to over 12 wt% solid loadings at flow rates from 100 gpm to over 2000 gpm.

| High Solids Separations | Sticky Solids Separations |

|---|---|

| Gore’s surface filtration technology enables producers to replace three steps: clarifier + sand/media filter + polish filter – with just one step. | Gore’s filter microstructure mitigates fine particle penetration of the filter, allowing:

|

The unique microporous structure of Gore’s surface filters, overall geometry, and filter operation expertise offers a highly efficient and cost-effective means of eco-friendly lithium brine filtration.

Want to learn more? Download our lithium separations brochure!

Resources

Data Sheet: High Durability Filter Sock - Polypropylene Felt 441 g/m2 (13 oz/yd2)

Data Sheets, 69.37 KB

Membrane Filter Socks for the Recaust Plant

Brochures, 463.23 KB

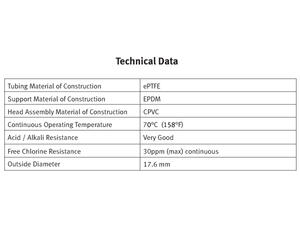

Data Sheet: GORE® Filter Tube Assemblies

Data Sheets, 154.39 KB

View all Resources for GORE Membrane Filter Sock and Tube assemblies

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.