Data Sheet: GORE® VNA Microwave/RF Test Assemblies

Data Sheets, 596.46 KB

Constant and/or highly repetitive cable movement can compromise the measurement precision of high-performance vector network analyzers (VNAs). With the most precise measurements, GORE VNA Microwave/RF Test Assemblies from W. L. Gore & Associates set the industry standard for VNAs through 70 GHz. They’re specifically engineered for metrology and critical test and measurement applications. Leading manufacturers choose our test assemblies because of the improved performance they see in their equipment.

When it comes to long-length microwave coaxial assemblies, their phase/loss stability and repeatability, as well as shielding effectiveness, have historically not been well documented. This is largely due to the low demand for these types of assemblies and lack of standardized testing procedures. Published by W. L. Gore & Associates, White Paper: Phase Stability, Loss Stability and Shielding Effectiveness of Long Length provides some much-needed insights into this type of equipment to help operators, engineers and manufacturers find the right extended-length solutions.

Secondary after-filter blinding was eliminated. GORE membrane filter bags were cost justified in less than one month. Bag life was expected to approach two years. Customer quickly converted all SAN and ABS dryer systems to GORE membrane filter bags. Customer increased profits substantially in these areas.

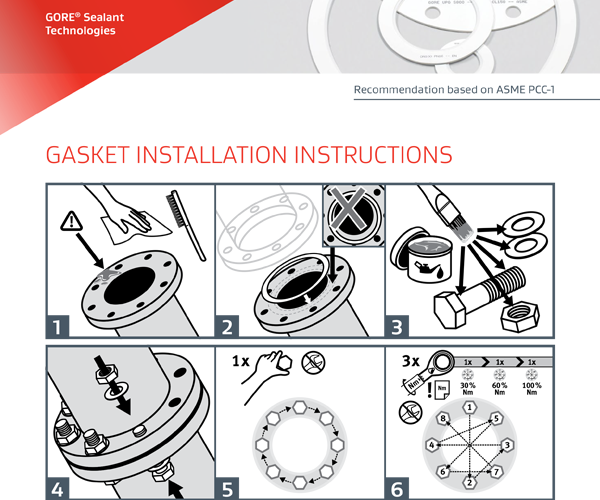

Installation Guide: Bolted Flange Assembly Instructions

Installation Guides, 135.05 KB

Visual step by step instructions for proper bolted flange assembly.

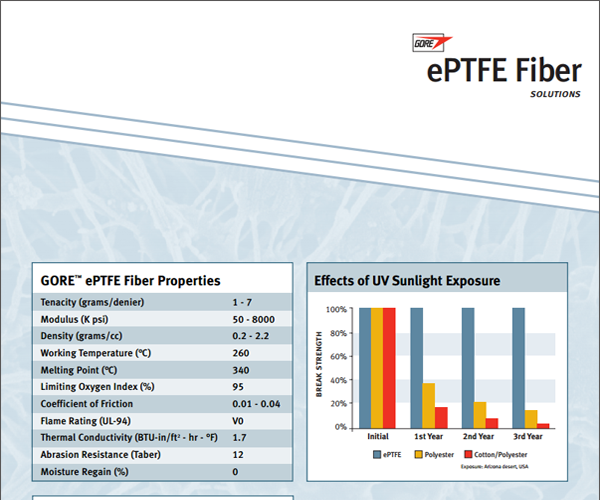

Data Sheet: Gore ePTFE Fiber Solutions

Data Sheets, 2.71 MB

Gore fiber is composed of proprietary ePTFE – a uniquely designed fluoropolymer fiber – with a microporous structure and specific engineered physical qualities that transform products from the ordinary to the extraordinary.

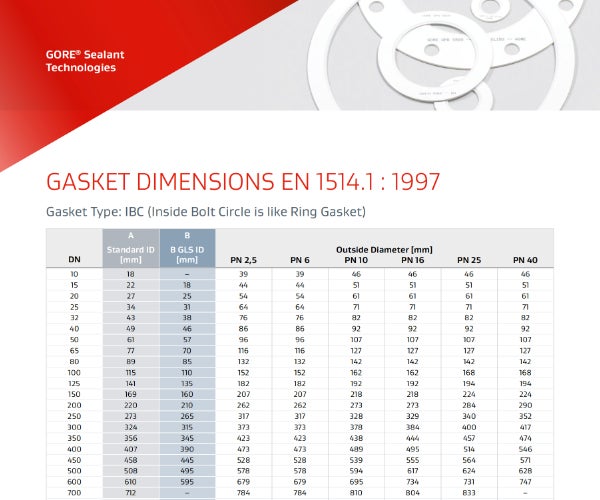

Gasket Dimensions according to EN 1514-1: 1997

Installation Guides, 142 KB

Dimensions applicable to flanges according to EN1092-1 among others.

The filter bags provided over 12 months of less than 6" DP service and allowed continuous production. At the design rate of 2,080 lb/hr failure occurred because of wear at the snap band cuff due to cage movement.

A Comparison of Measurement Uncertainty in Vector Network Analyzers and Time Domain Reflectometers

White Papers, 2.69 MB

Measurement uncertainty has a direct impact on the reliability of test instruments. To determine if there is a quantifiable difference in measurement uncertainty between the TDR and VNA, W. L. Gore & Associates performed a series of experiments, initially testing six cable assemblies in controlled conditions on each instrument.

GORE® Protective Vents - Weldable Membrane Series - Data Sheet & Installation Guide

Data Sheets, Installation Guides, 165.07 KB

Low-profile, 100% ePTFE vents are designed for automated installation which incorporate heat or ultrasonic welding processes. Ideal for solar energy systems, they provide a robust mechanical bond in conjunction with rapid equalization of pressures.

GORE® Protective Vents - Adhesive Series - Quality Assurance Testing

Technical Information, 151.92 KB

Multiple testing processes ensure the quality and reliability of Adhesive vents: membrane tests for air flow and water entry pressure, lot testing of finished product dimensions and adhesive bond, and a manual, visual inspection of every part.