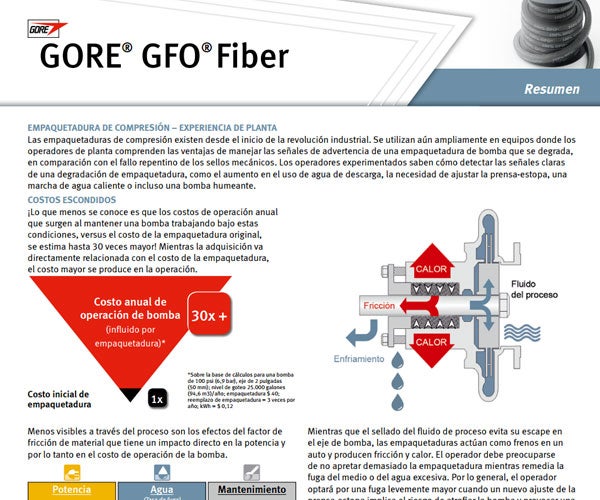

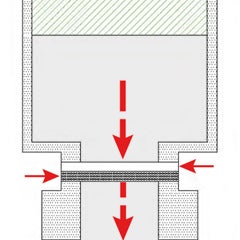

Materials Technology: Water Entry Pressure Testing

Technical Information, 161.8 KB

Description of standard test used to measure a membrane's ability to stop aqueous flow, and diagram of the apparatus used for water entry pressure testing.

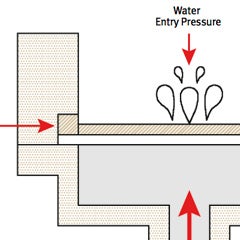

Materials Technology: Sealing GORE™ Membranes to Plastic Parts

Technical Information, 128.63 KB

A variety of methods can be used to seal GORE™ Membranes to plastic parts. This document describes two common methods: heat sealing, and ultrasonic welding.

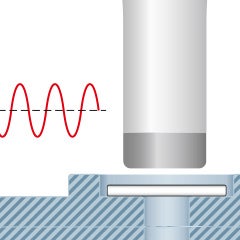

Materials Technology: Resistance Testing

Technical Information, 143.84 KB

Description of standard test used to measure resistance of high flowing media, and diagram of the apparatus used for resistance testing.

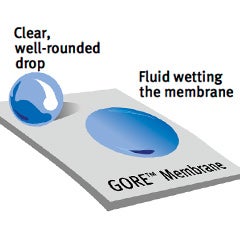

Materials Technology: Oil Repellency

Technical Information, 210.82 KB

Description of GORE™ Oleophobic Membranes, oil repellancy testing, oil ratings, and surface tensions of typical fluids.

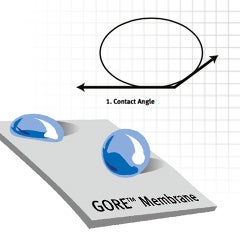

Materials Technology: Venting With Hydrophobic vs. Oleophobic Membranes

Technical Information, 254.66 KB

The key to choosing the appropriate membrane technology for a given application is understanding the environmental conditions and the surface tension of the fluids that the vent will encounter.

Materials Technology: Gurley Airflow Testing

Technical Information, 177.98 KB

Description of standard test used to measure airflow of low flowing media, and diagram of the apparatus used for Gurley airflow testing.

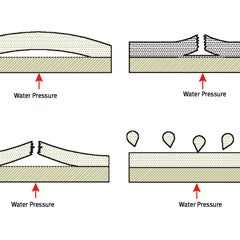

Materials Technology: Bond Strength Testing

Technical Information, 185.79 KB

Description of standard test used to measure the force required to separate the layers of a laminate, with diagrams of possible outcomes when water entry pressure has been exceeded.

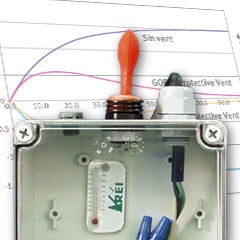

The Impact of Temperature Cycling on Sealed Enclosures

Technical Information, 370.15 KB

Fluctuations in temperature create failures in electronic devices due to pressure differentials. Gore application engineers simulated a rapid heating and cooling cycle to understand the effects of pressure differentials. This document describes the test procedures and results.

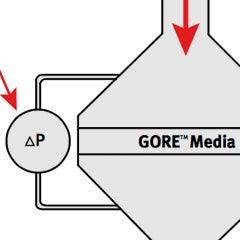

Programa de Sello de Calidad: GORE® GFO® Fibers

Technical Information, 177.97 KB

Calidad asegurada con el “Programa de Sello de Calidad” de Gore. En el mercado se ofrecen muchas empaquetaduras de PTFE/grafito. Mientras todas se vean iguales, vale la pena constatar que existen diferencias enormes en la calidad y el rendimiento actual del producto de muchas soluciones de empaquetadura ofrecidas.