Case Study: PVC - Spray Dryer Dustex Reverse Air Collector Filtering using GORE® Filter Bags

Case Studies

Airflow increased by 10%. Production rated increased. Lower operating DP 1-2". Improved cake release eliminated product discoloration and product contamination. Bags attained 5+ years of service.

Lower operating DP (5"-7" DP) improved cake release, allowing increased airflow through collector. Bleed-through stopped, allowing capture of product. First set of bags lasted more than five years.

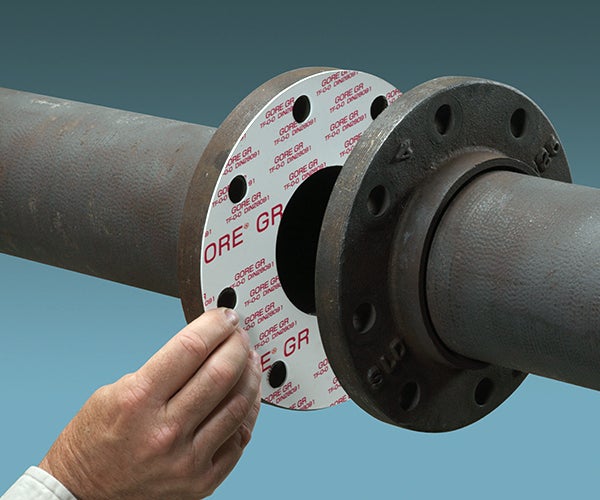

Hoja de especificaciones: Junta de Plancha GORE® GR

Data Sheets, 1.19 MB

Fiabilidad de sellado sin igual. Obtenga los beneficios del sellado PTFE sin los problemas de fluencia en frío. Con una fiabilidad de sellado sin igual, la junta de plancha GR de GORE® proporciona un nivel de resistencia a la alta temperatura y blowout superior a cualquier otra junta de plancha de PTFE.

Modern civil and military aircraft depend on quality microwave assemblies like those produced by W. L. Gore & Associates for reliable performance. Yet the challenges of installation in tight airframe environments can often degrade lower-quality cables, requiring replacement long before the expected end of life. In Gore’s White Paper: Reducing Life Cycle Costs with Reliable Airframe Microwave Assemblies, we take a closer look at how higher-quality cable assemblies deliver lower costs, greater productivity, and a host of additional benefits.

Data Sheet: GORE-FLIGHT® Microwave Assemblies for Aircraft

Data Sheets, 1.69 MB

Extreme aerospace conditions can compromise the performance of airframe cable assemblies. Aside from the challenges of installation, rigorous flight conditions bring rapid temperature and pressure changes, as well as potential contamination from fuels, oils and fluids. Maintaining signal integrity in these tough environments is essential to ensuring the reliability of an aircraft’s sophisticated electronic systems.

GORE-FLIGHT® Microwave Assemblies for Aircraft are lightweight, durable and proven to improve fuel efficiency and increase payload while reducing operating costs.

Selecting Microwave/RF Cable Assemblies for Reliable Performance Over Time

White Papers, 5.48 MB

A recent study showed that users of microwave/RF cable assemblies expect high-quality, long-lasting performance; however, more than 75 percent of these users are replacing their assemblies frequently, with the most common cause of failure identified as damage during installation or operation. Depending on the frequency, the direct cost for replacing cable assemblies on a single piece of equipment can reach $250,000 over the life of the system — and this does not include the indirect costs such as delayed production schedules, bad products, or retesting and calibration.

This design has been superseded by RCN 9047-26

Technical Information: GORE® Performance Fiber for High Performance Ropes

Technical Information

Extended service life and decreased surface temperature are two key features of GORE Performance Fiber for High Performance Ropes.

Production goals met and exceeded without enlarging the baghouse. The bags have performed consistently well for the past 12 years, with scheduled changeouts every 24 months (although bag life has reached 30 months).

The first set of GORE membrane filter bags lasted 50 months and provided more than 48 months of service at maximum production. Over a four-year period, three bag changeouts were averted, saving $43,200 in labor and $32,400 in bags.