Mechanical Engineering Magazine: Letting Surfers Vent

Industry Articles, 481.1 KB

DECEMBER 2009 // Author Harry Hutchinson interviews engineer and lifelong surfer Peter Casica about his innovative use of GORE® Protective Vents to prevent damage to surfboards. Casica knew temperature extremes created pressure differentials within the board, causing deformation, delaminations and leaks. See how a GORE® PolyVent solved the problem.

Electronics Protection Magazine: The Unknown Problem with Airtight Enclosures

Industry Articles, 1.99 MB

SEPTEMBER 2012 // Product Specialist Jason Zambotti discusses the pitfalls in using robust airtight and watertight enclosures to meet stringent IP or Electrical standards for use in rugged outdoor environments. Along with examining the reasons why pressure differentials cause airtight housings to leak, the article offers an in-depth discussion of the relative benefits and flaws of several solutions.

LEDs Magazine: Equalize Pressure to Ensure Reliable LED-Based Outdoor Luminaires

Industry Articles, 1.87 MB

MARCH 2013 // Applications Engineer Gary Chan examines the hidden design challenge of managing pressure differentials in outdoor LED lighting systems, and discusses how proper venting can extend product reliability and durability by protecting housing seals, joints and connections from stress and premature failure. The role of venting in protecting against condensation, thermal shock, water ingress and contaminants is also considered.

Results showed no visible emissions, excellent and consistent product yield, and secondary filter blinding significantly reduced. No bag failures since installation.

OSP Magazine: Under Pressure — Stress-Reducing Tactic for Enclosures

Industry Articles, 1.49 MB

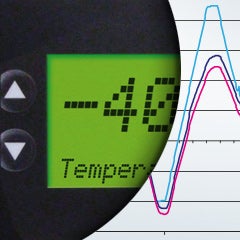

September 2013 // Applications Engineer Gary Chan explains how a non-vented sealed enclosure can pass the IEC 60068-2-1 cold temperature test protocol. However, by monitoring pressure throughout testing, the sudden temperature changes cause the internal pressure to reach levels that result in compromised seals.

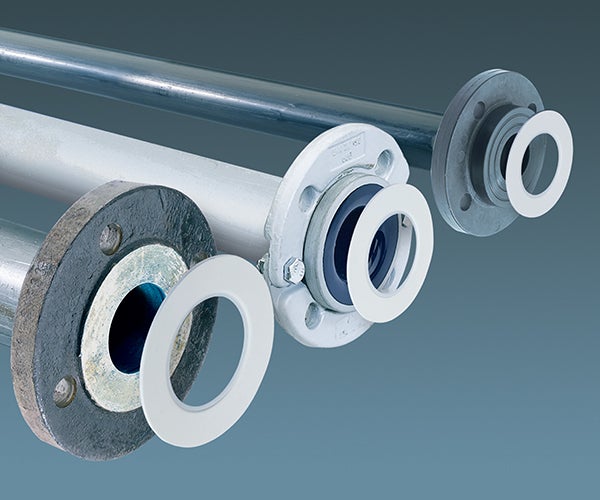

Hoja de especificaciones: Las juntas universales GORE® (Style 800)

Data Sheets, 960.88 KB

Las juntas universales GORE® (Style 800) se utilizan para sellar todos los tipos de bridas en las tuberías de procesos químicos. Diseñadas para satisfacer las necesidades de muchos materiales de tuberías distintos, son ideales para material de junta estándares para sistemas de acero, acero revestido de vidrio, y sistemas FRP, siempre que se puede usar una junta no metálica.

Reliability Testing of GORE® Protective Vents in LED Luminaires

White Papers, 1.35 MB

JANUARY 2013 // This 12-month test evaluates the effects of changes in temperature, pressure and humidity on two IP66-rated outdoor LED luminaires – one with a GORE® Vent, one sealed. Results show that venting, to equalize internal pressures, improves luminaire reliability.

Reliability Testing of GORE® Protective Vents in Telecommunication Enclosures

White Papers, 659.05 KB,

MAY 2013 // Both vented and non-vented IP67 telecommunications enclosures were tested for reliability after exposure to real-world challenges: sudden temperature changes, temperature changes with concurrent water exposure, and repeated cycles of hot/cold and wet/dry conditions.

Hoja de especificaciones: Junta de estanqueidad GORE®

Data Sheets, 284.17 KB

Junta para bridas de grandes diámetros. El cordón sellante GORE®, la junta original automoldeable, está maquinada para el sellado confiable de bridas grandes, complejas o dañadas.

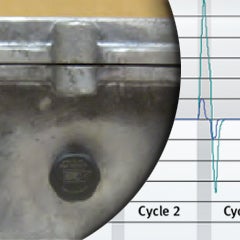

Temperature Cycling Tests to Evaluate Product Life

White Papers, 1005 KB

JULY 2014 // These tests of vented and non-vented IP66-rated junction boxes demonstrate that GORE® Vents can help lengthen solar equipment service life, because they preserve seal integrity, block liquids and contaminants, and effectively diffuse water vapor to minimize condensation.