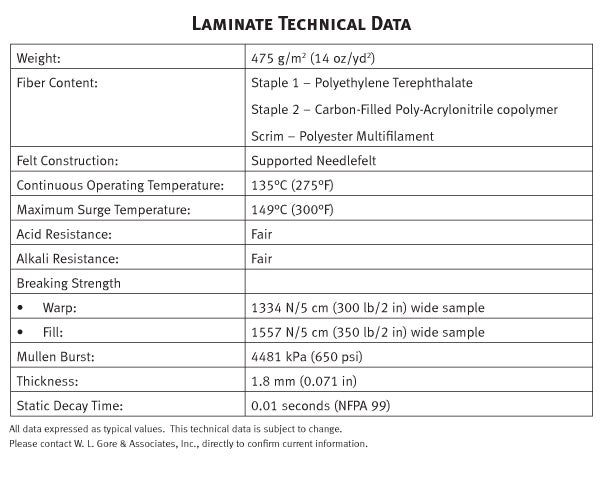

Data Sheet: Polyester Felt, Anti-Static GORE® Filter Bag 475 g/m2 (14 oz/yd2)

Data Sheets, 153.55 KB

A 135°C (275°F) maximum service temperature, anti-static polyester felt filter bag for use in pulse-jet style dust collectors where static dissipation is required.

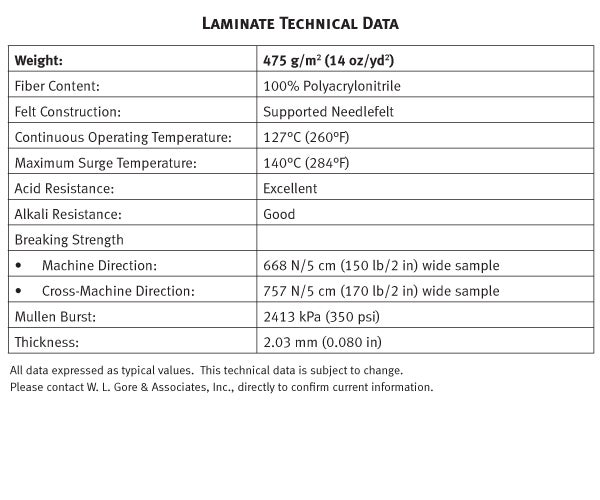

Data Sheet: Acrylic Felt GORE® Filter Bag 475 g/m2 (14 oz/yd2)

Data Sheets, 109.62 KB

A maximum 127°C (260°F) service temperature, acrylic felt filter bag for use in pulse-jet style dust collectors.

Efficiency of LED Luminaires Significantly Increased

Case Studies, 2.36 MB

WE-EF develops, manufactures, and markets high quality lighting for outdoor use. The focus is on innovative optical systems, good heat management, and high IP ratings. Its aim is to design lighting that is extremely durable and efficient despite harsh climatic conditions. This is a particular challenge in the case of the LEDs that WE-EF uses in newer street and area lighting luminaires.

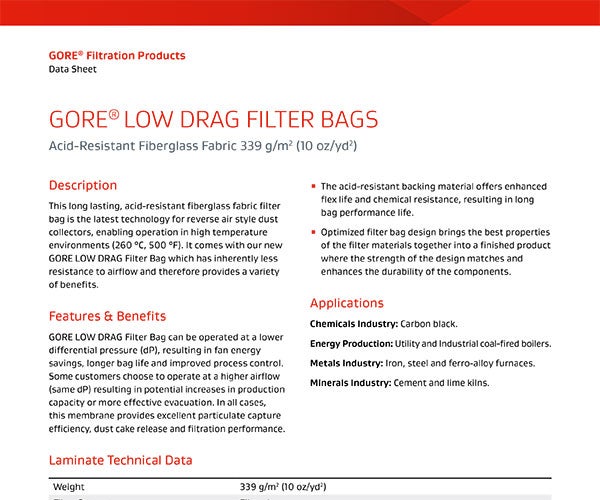

Data Sheet: GORE® LOW DRAG Filter Bags 3170, Fiberglass Fabric, 339 g / m2 (10 oz / yd2)

Data Sheets, 52.44 KB

This long lasting, acid-resistant fiberglass fabric filter bag is the latest technology for reverse air style dust collectors, enabling operation in high temperature environments (260 °C, 500 °F). It comes with our new GORE LOW DRAG Filter Bag which has inherently less resistance to airflow and therefore provides a variety of benefits.

Brochure: GORE® Protective Vents for Heavy Duty Equipment

Brochures, 669.81 KB

How do Your Electronics Survive in Harsh Environments?

Dirt, water, humidity, and high temperatures: Equipment used in heavy-duty industries must be able to reach peak performance even in the harshest conditions.

GORE® Protective Vents - Telecommunication Systems

Brochures, 1.09 MB

High-value telecommunications components can benefit from higher reliability, and lower manufacturing, maintenance and warranty costs, with GORE Protective Vents.

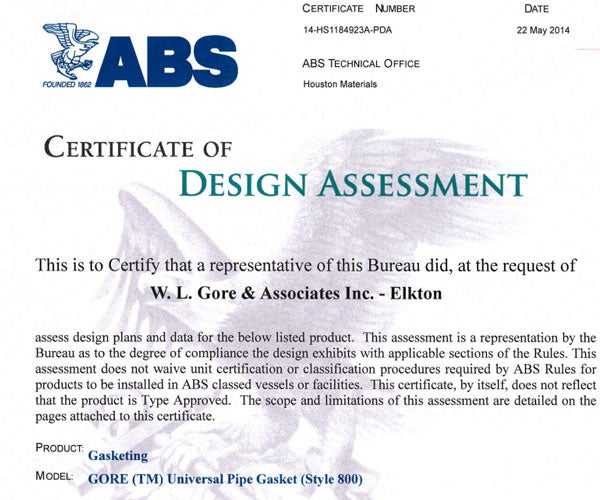

GORE® Universal Pipe Gasket (Style 800): Marine and Offshore Applications Certificate

Certifications, 1.71 MB

GORE® Universal Pipe Gasket (Style 800) has received a PDA (Product Design Assessment) certificate under the ABS Approval Program. The scope and limitations of this assessment are detailed on the pages attached to this certificate.

GORE® Protective Vents - Solar Energy Systems

Brochures, 1.33 MB

GORE® Vents help manufacturers improve the cost-effectiveness, production efficiencies and life expectancy of solar energy systems and components.

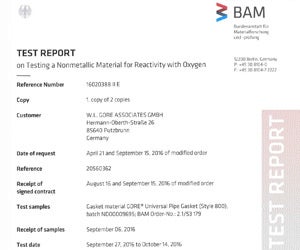

GORE® Universal Pipe Gasket (Style 800): Oxygen Service (BAM) Report

Certifications, 3.08 MB

The Federal Institute for Materials Research and Testing (BAM) tests the sealing material compatibility for use in flanged connections with liquid and gaseous oxygen. Further information on the test procedure and the result can be found in the following test report. Please note that the test was conducted on the version of this product with no printing ink product identification.

CAUTION: Extra care is advised to ensure that the gasket surface is free from particulate contamination that accumulates due to static charge.