Pressure Equalization for Extended Life: a Five-Year Study of GORE® Protective Vents in Outdoor Enclosures

Technical Information, United States

A five-year study demonstrates that GORE® Protective Vents can extend the service life of sealed outdoor enclosures, reliably protecting the integrity of the sensitive electronics within. The study, developed and conducted by Gore application engineers, measured pressure differentials in both non-vented and vented enclosures. The resulting effects on enclosure and seal integrity are dramatic.

Torsten Eifler,

Global Product Manager PolyVents,

Industrial Product Division

For outdoor electronics to function reliably, it’s essential to maintain the integrity of the sealed enclosure. Electronics often fail due to premature seal failure, which allows leakage, condensation or particulates into the enclosure. Seals typically fail when repeatedly stressed by extreme pressure differentials, due to rapid changes in ambient conditions.

GORE® Protective Vents rapidly equalize pressure differentials, preventing stress on seals and minimizing the chance of premature seal failure that can cascade to product failure.

To demonstrate how GORE® Protective Vents can extend the service life of outdoor electronics, our engineers designed and conducted a five-year study comparing vented and non-vented enclosures.

Study Design

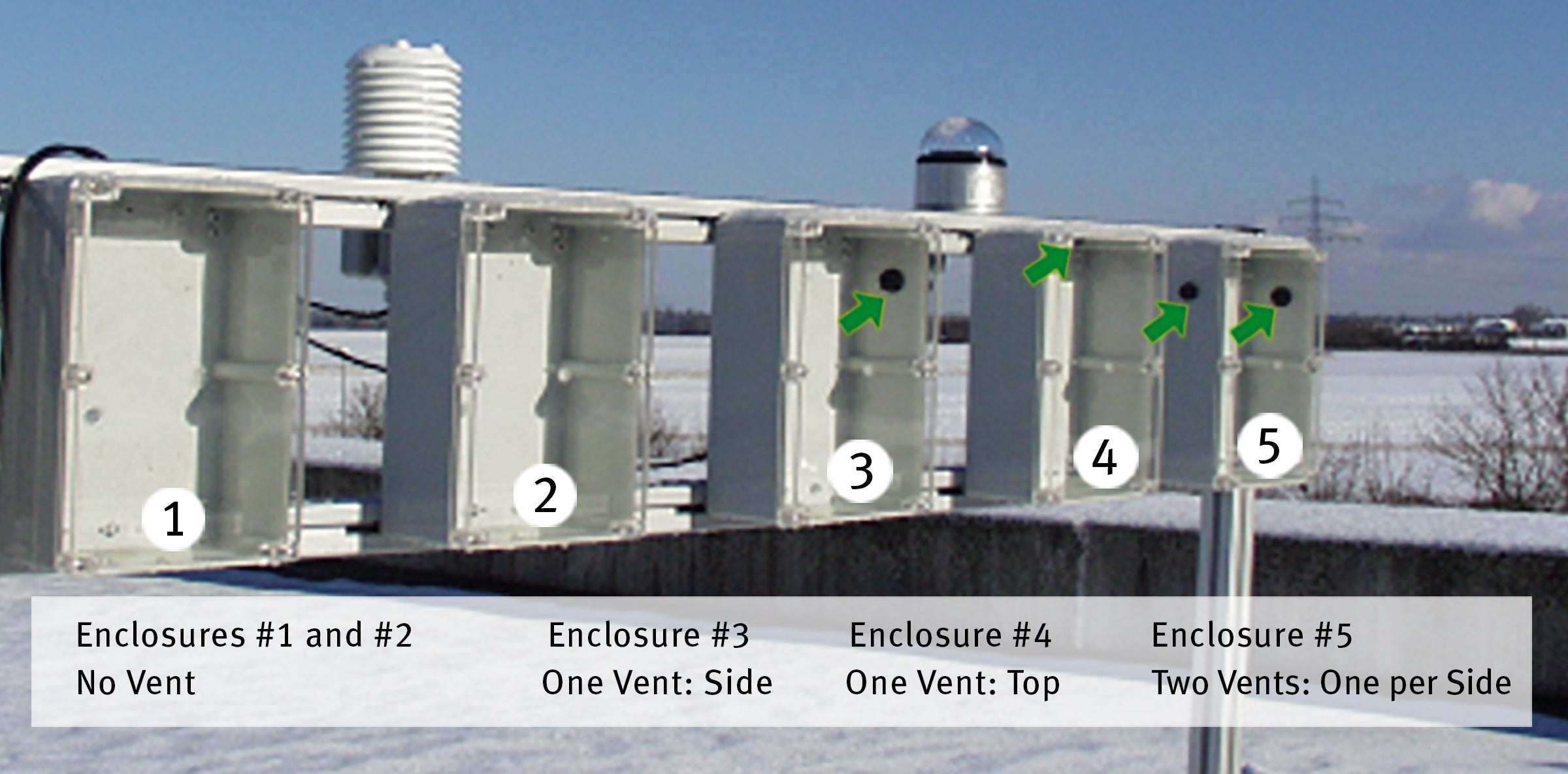

The study was conducted in Putzbrunn, just outside of Munich, Germany, from January, 2002 to August, 2007. It employed five identical polycarbonate outdoor electronic enclosures with Neoprene seals. Each was rated IP 65. Two of the enclosures were used “as-is”… without venting. In the other three enclosures, GORE® Protective Vents were installed in different locations, as shown below:

The GORE® PolyVent (PMF100320) used in the study

A sensor, installed in each enclosure, measured differential pressures every ten minutes, for the duration of the study. The enclosures were not opened until the study concluded.

Study Results

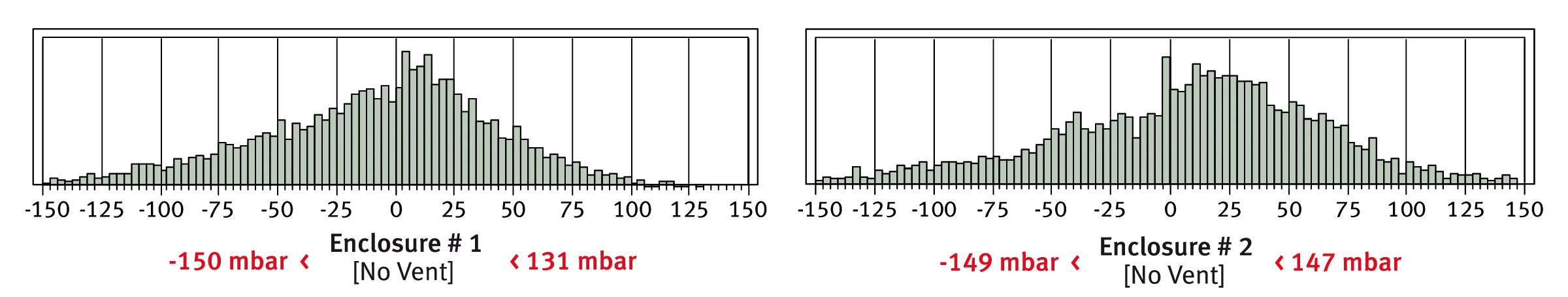

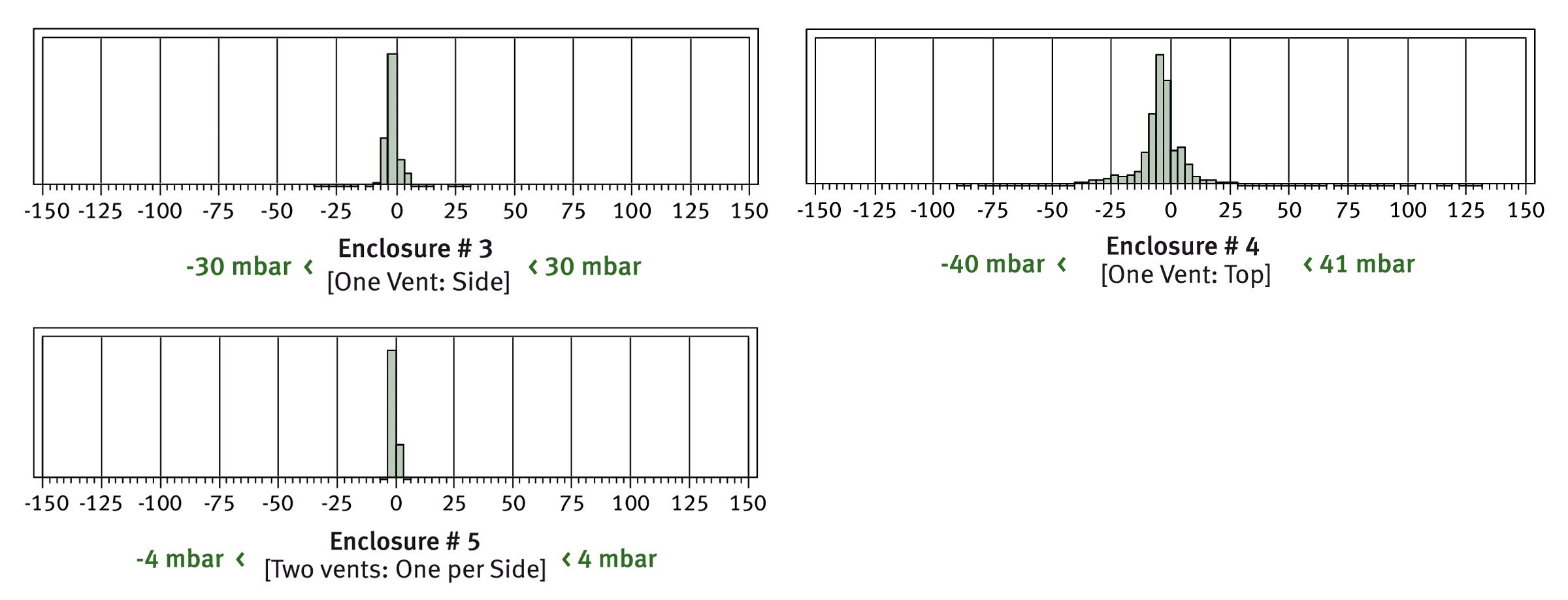

Compiled Data

The compiled data dramatically demonstrates the benefits of venting outdoor enclosures. Within the two non-vented enclosures, the sensors recorded extreme pressure differentials.

By comparison, the three enclosures with GORE® Protective Vents maintained almost atmospheric conditions, with minimal pressure differentials over the five-year period.

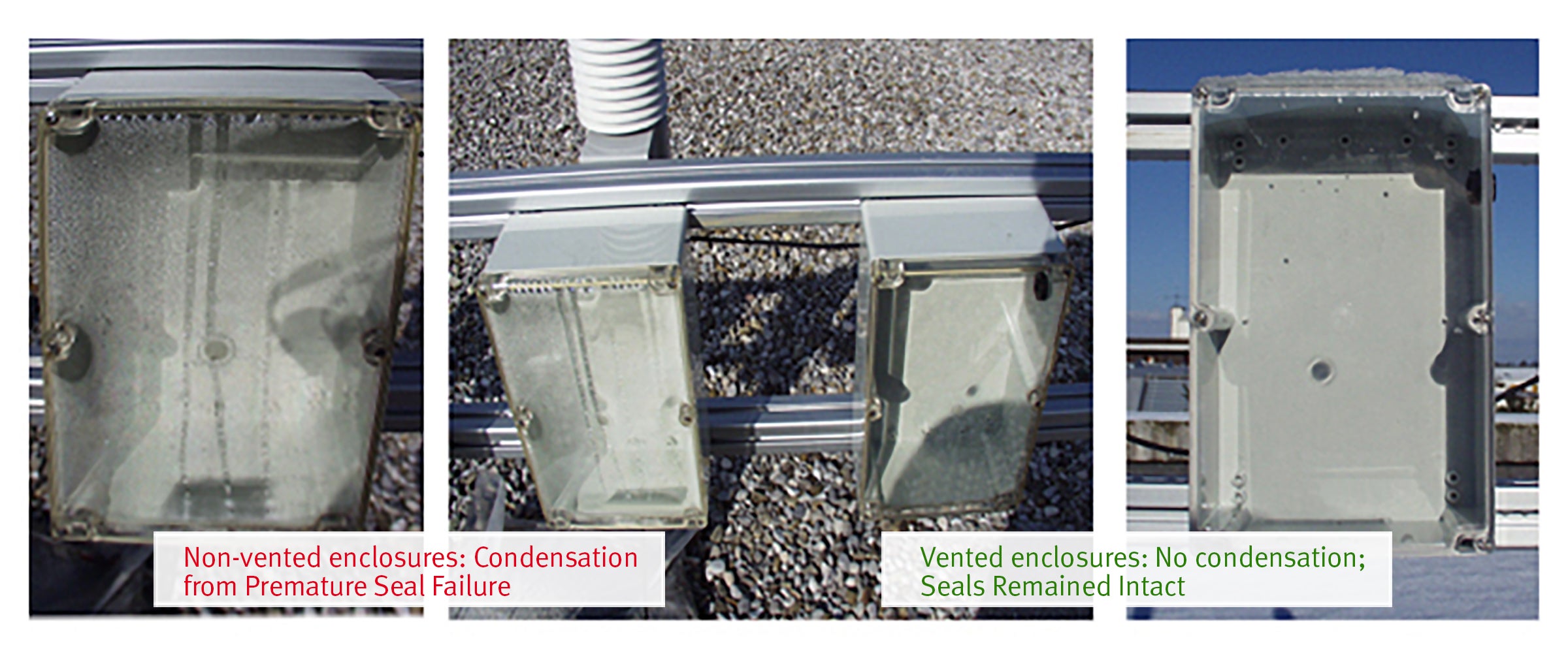

Post-Study Inspection of Enclosures

Because the GORE® Protective Vents rapidly equalized pressure differentials, there was virtually no stress on the seals, which were still intact at the end of the five-year study. Visual inspection confirmed no condensation, and no signs of water or dust ingress at the seals or cable entry.

In the non-vented enclosures, the extreme pressure differentials caused significant and repeated stress on the seals. The heavy condensation buildup shows that the seals failed before the five-year study ended, and allowed allowed water and contaminants to enter the enclosure.

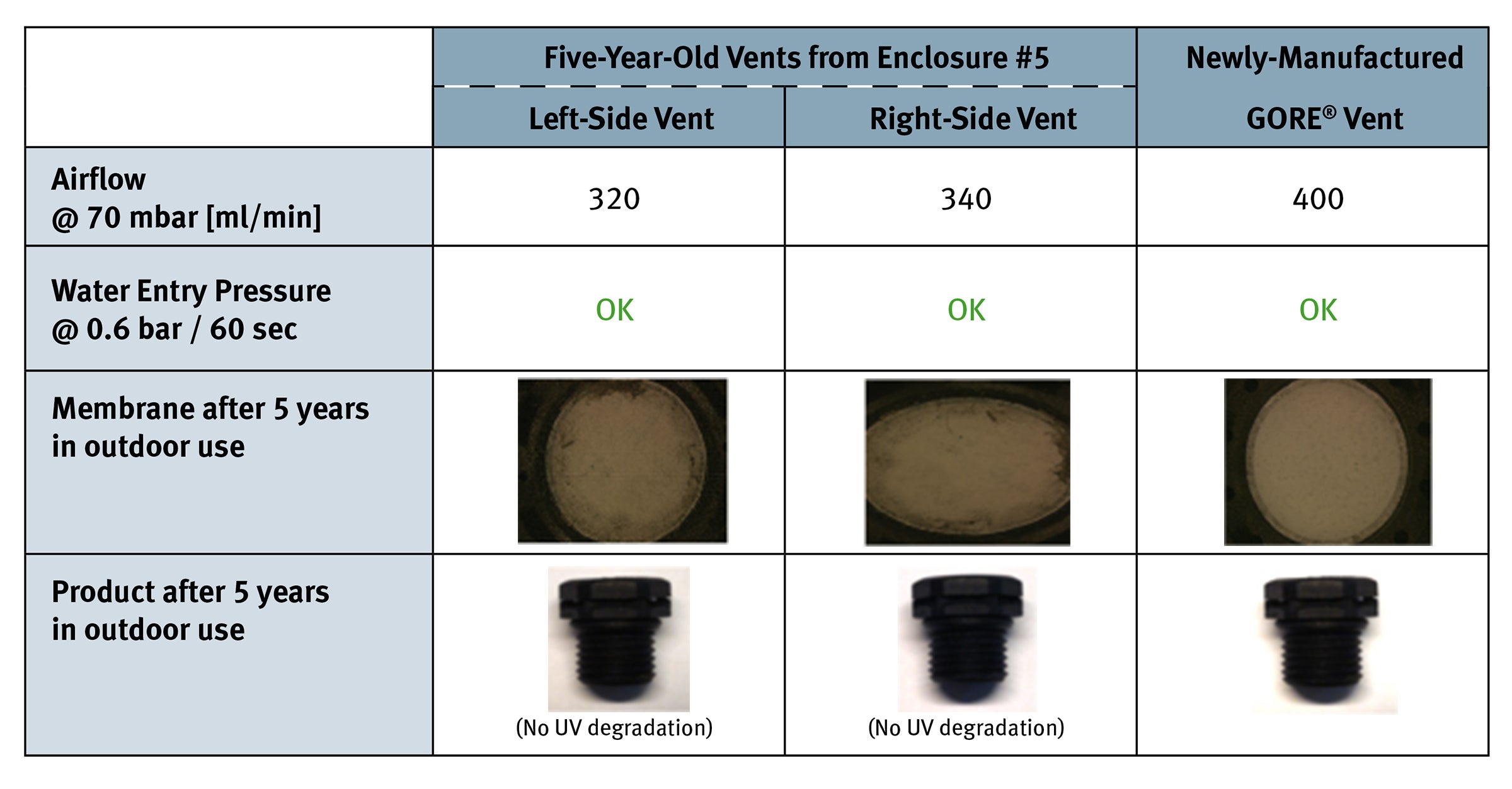

Post-Study Inspection of Vents

After more than five years of continuous outdoor use, the GORE® Vents used in the study were removed from the enclosures and evaluated against a newly-manufactured vent of the same type. The results illustrate the long-term reliability, and extended service life, of these vents.

Conclusions

This landmark five-year study demonstrated the effectiveness of GORE® Protective Vents in rapidly equalizing pressure differentials and eliminating the severe stresses that can cause premature seal failure.

The long-term reliability of GORE® Protective Vents can mean a longer service life for outdoor enclosures, and the sensitive electronics they protect. By preventing premature seal failure that would draw water and dust into the enclosure, GORE® Vents can dramatically reduce the chance that condensation, corrosion or contaminants will damage electronic components.

In the lab, in field studies and in customer applications worldwide, GORE® Protective Vents provide reliable, long-lasting protection for outdoor electronic enclosures.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.