GORE® Thermal Insulation for 5G Antennas

Enhance user experience with GORE® Thermal Insulation for 5G mmWave Antennas. Optimize heat management with minimal signal interference.

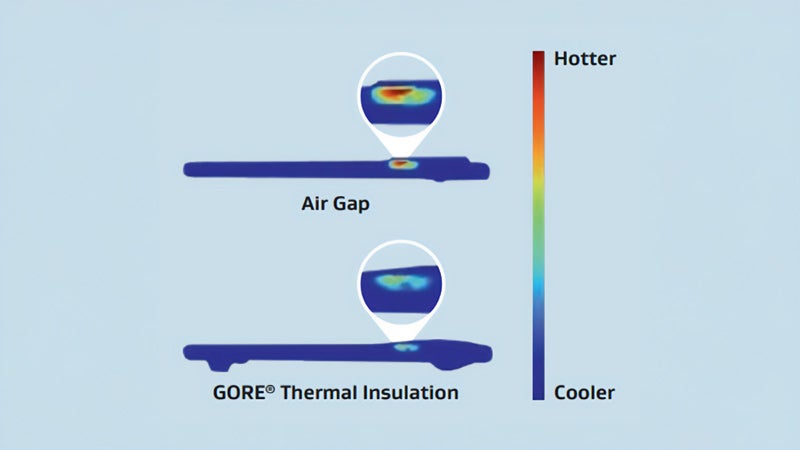

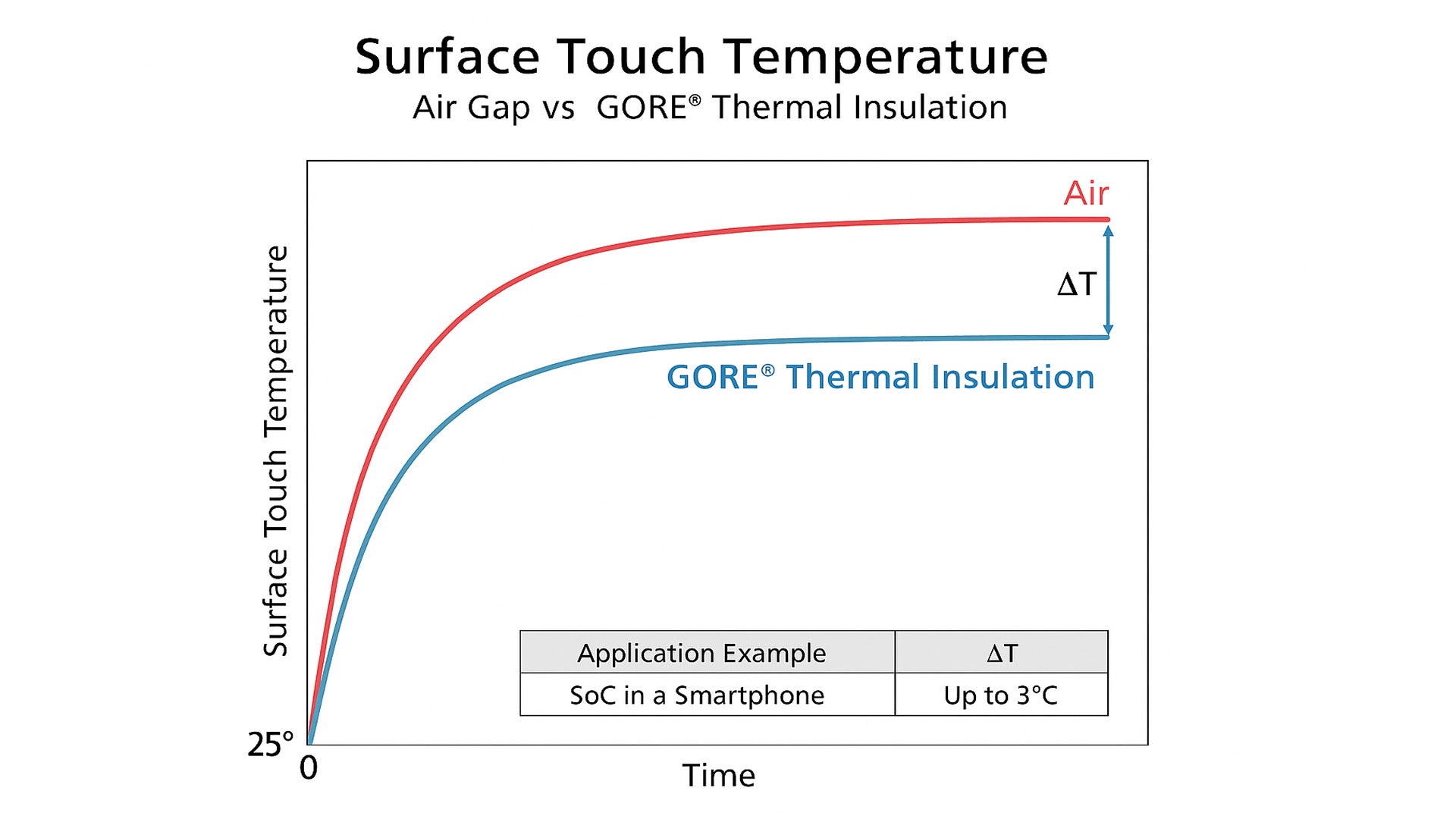

Reduce 5G Antenna Hot Spots with Thermal Management That’s Better Than Air

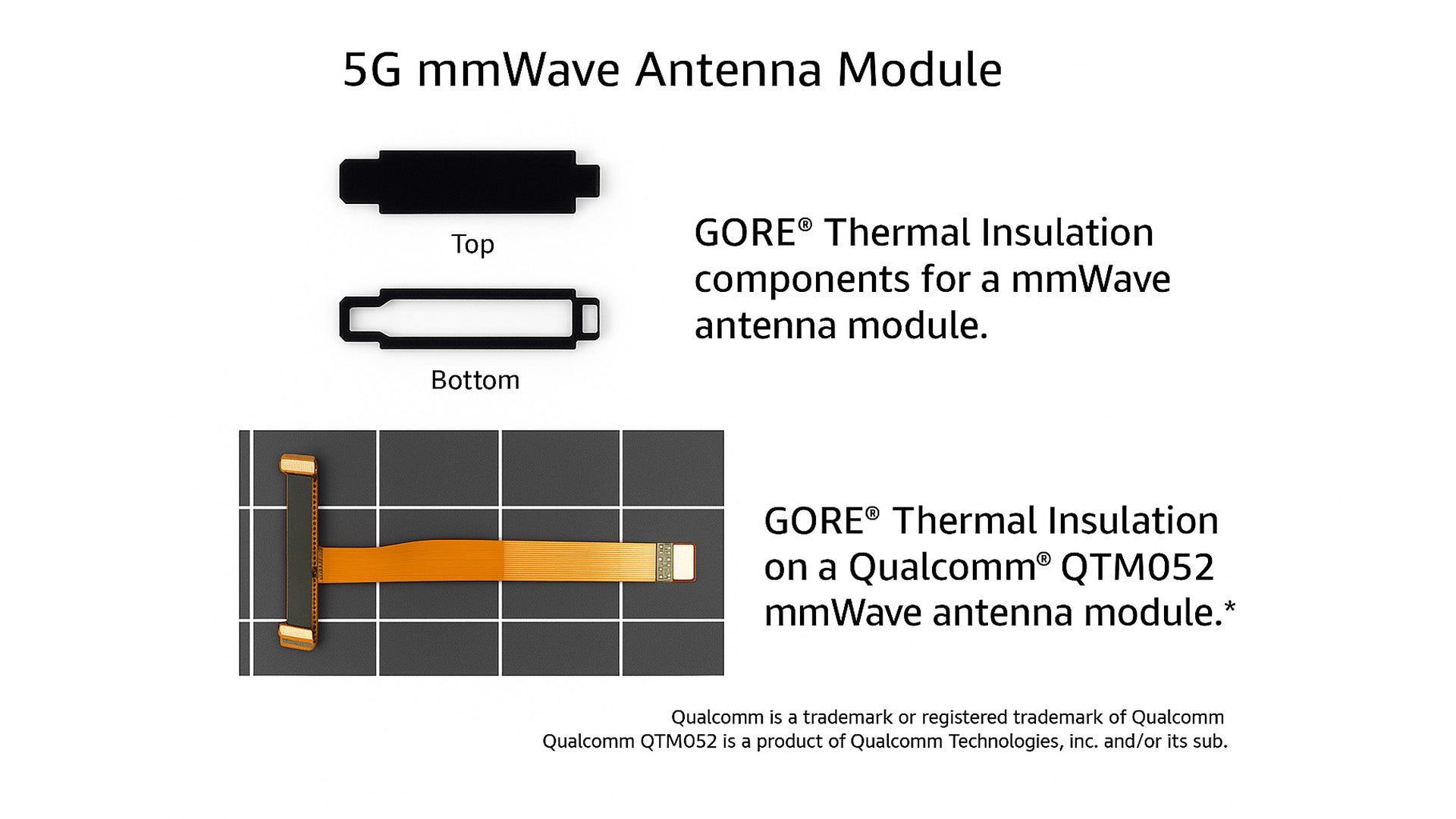

GORE Thermal Insulation for 5G mmWave antennas fits on top of antenna modules to prevent surface hot spots with minimal RF interference. It is compatible with commonly used Qualcomm® modules and custom shapes. This insulation reduces surface temperatures, maintaining 5G signal duration and enhancing the user experience.

*Qualcomm is a trademark of Qualcomm Incorporated.

The Effect Insulation Has on Heat Transfer

This video demonstrates the effect insulation has on heat transfer. Watch how rapidly heat melts a crayon with and without GORE® Thermal Insulation.

Assembling GORE Thermal Insulation for 5G Antennas

It’s easy to install GORE Thermal Insulation atop a 5G mmWave Antenna to maximize performance.

Technical Information

| Characteristic | ||||||

|---|---|---|---|---|---|---|

| Dielectric constanta | 1.46 | |||||

| Loss tangenta | 0.017 | |||||

| Typical signal loss with 350µm part | < 0.3 dB | |||||

| Insulation thickness availableb | 0.10 mm | 0.12 mm | 0.23 mm | 0.28 mm | 0.38 mm | 0.53 mm |

| Adhesive encapsulation width (minimum)c | 1 mm | 1 mm | 1 mm | 1 mm | 1 mm | 1.5 mm |

| Thermal conductivity (k)d | 0.021 W/m•K | 0.020 W/m•K | ||||

| Compression @ 100 kPa (14.5 psi) | 13% | 8% | ||||

| Specific heat capacitye | 1.8 J/g °C | |||||

| Bulk density | 0.37 g/cc | |||||

| Operating temperaturef | -40 °C to 100 °C | |||||

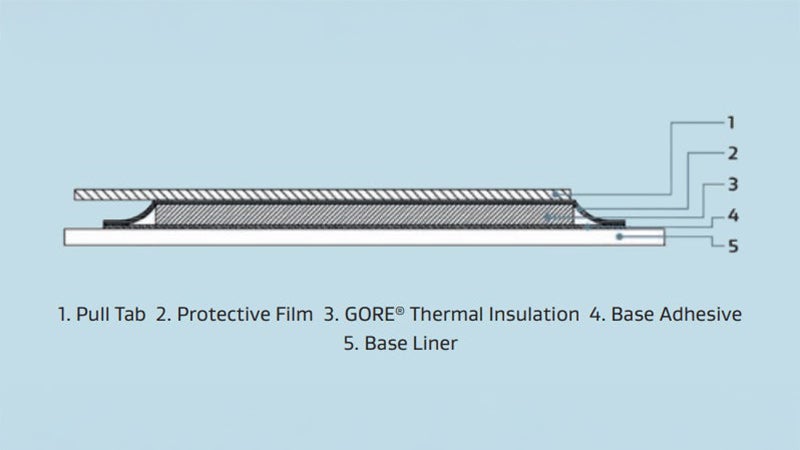

| Protective cover film | Black PET | |||||

| Adhesive type | Acrylic | |||||

| RoHSg | Meets threshold requirements | |||||

| Max part size | 100 mm × 200 mm | |||||

aNominal values representative of frequency range from 6 GHz to 70 GHz.

bNominal thickness based on reported values of thickness of each component of the stack-up.

cNominal minimum width.

dNominal conductivity value based on a modified version of ASTM C518.

eNominal heat capacity measured according to ASTM E2716 Method B at 75 °C.

fAlternate adhesives required to exceed 100 °C.

gTo the best of our knowledge, the product listed above does not have any restricted substances above the maximum concentration values listed in RoHS Directive 2011/65/EU and meets the substance restrictions of Article 4 of RoHS Recast including Commission Delegated Directive 2015/863.

*All values based on nominal characteristic and do not represent the specification and tolerance.

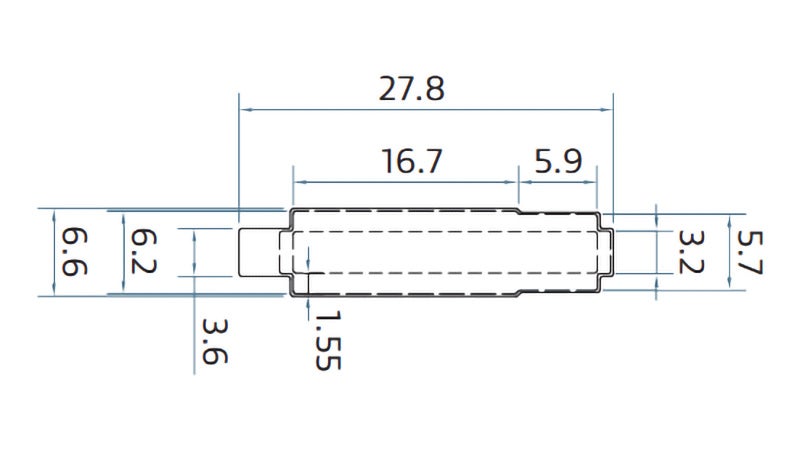

| Nominal thicknessa | 0.28 mm |

|---|---|

| Adhesive encapsulation width (minimum)b | 1 mm |

| Dimensions | Image  |

aNominal thickness based on reported values of thickness of each component of the stack-up.

bNominal minimum width.

**Could fit a Qualcomm® QTM545 module, product of Qualcomm Technologies Inc. and/or its subsidiaries.

With ultra-low thermal conductivity and dielectric constant, GORE Thermal Insulation prevents throttling of 5G data rates by reducing surface temperatures and minimizing 5G signal interference.

Case Studies

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 410 506 7812

Have questions or unique requirements?

Our experts are here to guide you.