Data Sheet: GORE® High Performance Wires for Defense Land Systems

Data Sheets, 1.54 MB

Ground forces are contemplating vehicle electrification to simplify maintenance and reduce logistical problems with fossil fuels. But electrification means increasing voltages to avoid weight gain in wiring systems. These higher voltages put more stress on wires and risk damage. W. L. Gore & Associates is on duty with an optimal solution to these challenges.

Get Complimentary Samples for Prototyping & Evaluation

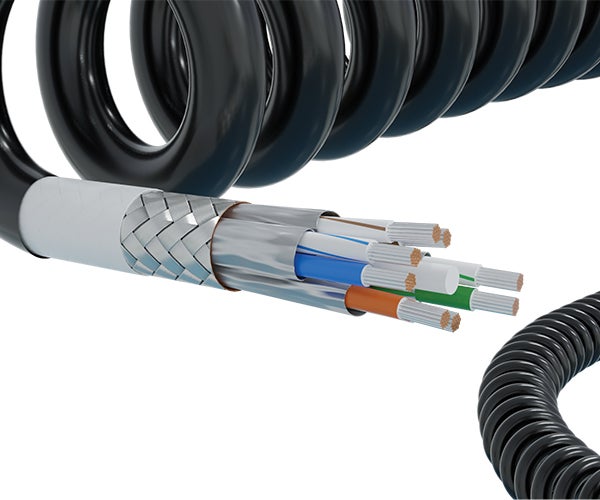

Data Sheet: GORE® Coiled Cables (High-Speed Data/Video) for Defense Land Systems

Data Sheets, 819.67 KB

Modern vectronics and carry-on equipment rely on cables to deliver fast, accurate Intel and uphold communication to ensure operational readiness, success and safety. As a trusted partner to ground forces, W. L. Gore & Associates offers a compact, durable custom cable for high-speed data and video transfer that repeatedly outperforms conventional substitutes.

Looking Beyond the Spec Sheet: Understanding the cold durability performance of fluoropolymer bags

Industry Articles, 409.67 KB

When comparing containment systems for cold chain use, it is critical to understand all the factors that can affect performance. Although polymer bags are an excellent choice for this application, not all polymer films perform the same way, even if their specifications rate them for use at low temperatures. A full suite of application testing is necessary to determine whether a bag will hold up to all the rigors of handling and shipping at extremely cold temperatures.

Data Sheet: GORE® Coiled Cables (Radio Communications) for Defense Land Systems

Data Sheets, 535.03 KB

Soldiers rely on radios to communicate real-time situational awareness for a competitive edge during defense ground missions. Backed by decades of proven reliability, durability and comfort, the military has relied on tailored-made coiled cables from W. L. Gore & Associates in thousands of radio systems.

Heerlen

Eisterweg 4

6422 PN Heerlen

The Netherlands

Netherlands (Sales Office)

+31 / 13 / 5074700

Event

It’s that time of the year again! Come visit us at AISTech and see Gore Filtration Solutions in person.

May 16, 2022 - May 19, 2022

Visit Gore at the AISTech, the Iron & Steel Technology Conference and Exposition in Pittsburgh, Pennsylvania (Booth 1952). Learn more about our innovative GORE® LOW DRAG Filter Bags, with our improved airflow and meltshop draft which can support the steel industry by meeting the environmental challenges while realizing lower operating costs.

Learn more: https://www.aist.org/conference-expositions/aistech