GORE® LOW DRAG Filter Bags for reverse air & pulse-jet baghouses

Technical Information

A cost-effective and reliable choice for dust & particulate matter collection

Whether you are using pulse-jet baghouse technology or reverse air filter bags, you need to be confident that your process meets the regulations around particulate matter compliance testing. GORE® LOW DRAG Filter Bags are available for both pulse-jet and reverse air baghouse systems, bringing the benefits of improved filtration efficiency, low energy use, and long bag life to your industrial process.

Article: Reducing emissions while achieving production goals

Industry Articles, 1.92 MB

Article from Global Cement (July 2022): OYAK Cement is committed to minimizing its environmental impact by investing in the best available technologies. W. L. Gore & Associates offered an opportunity to them to reduce emissions and save energy costs while achieving production goals.

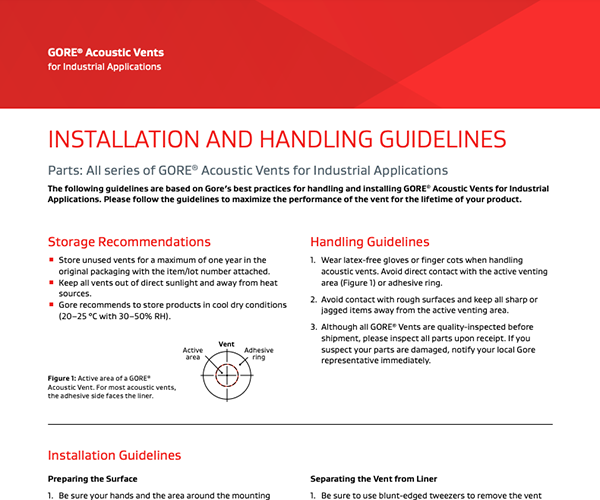

GORE® Acoustic Vents for Industrial Applications - Installation and Handling Guidelines

Installation Guides, 393.78 KB

These guidelines are based on Gore’s best practices for handling and installing GORE® Acoustic Vents for Industrial Applications. Please follow the guidelines to maximize the performance of the vent for the lifetime of your product.

Thank you for your interest in our case study. The link to your document is below. Do not hesitate to contact us for any questions or support needed.

Your Gore Mobile Electronics Team

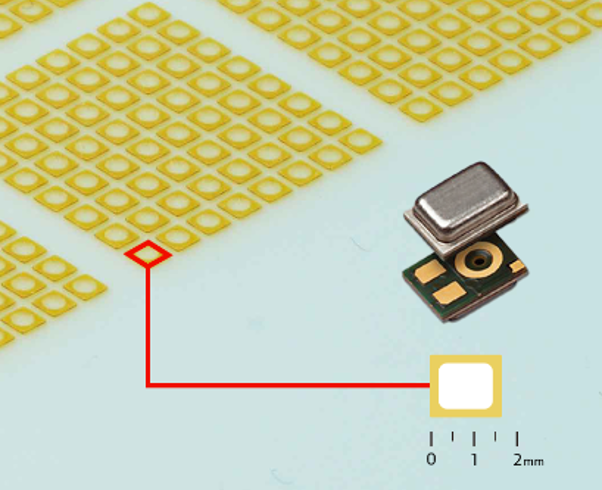

High-speed printed circuit board assembly may compromise the integrity of MEMS microphones. Damage and contamination cause yield loss, performance degradation, and higher production costs.

Brochure: GORE® MEMS Protective Vents – Style 300

Brochures, 203.04 KB

Greater protection. Simpler design.

The GORE® MEMS Protective Vents - Style 300 is installed inside the MEMS microphone during the microphone packaging process to provide component-level IP68 water and dust protection without any special handling during the circuit board assembly process.

Our pioneering venting solution eliminates the need for a separate acoustic vent installed on the housing, reducing complexity and saving space in the acoustic channel of water-protected devices.