GORE® Thermal Insulation for Mobile Devices

GORE® Thermal Insulation is an advanced thermal management solution with a conductivity lower than air that enhances heat spreading.

Meet Growing Thermal Challenges in Mobile Devices

GORE Thermal Insulation increases design flexibility and the ability to direct heat through greater control of z-axis thermal conductivity. Improved z-axis control means superior spreading options that enable components to:

- perform at higher levels for longer periods

- accommodate shrinking form factors

- meet surface temperature requirements

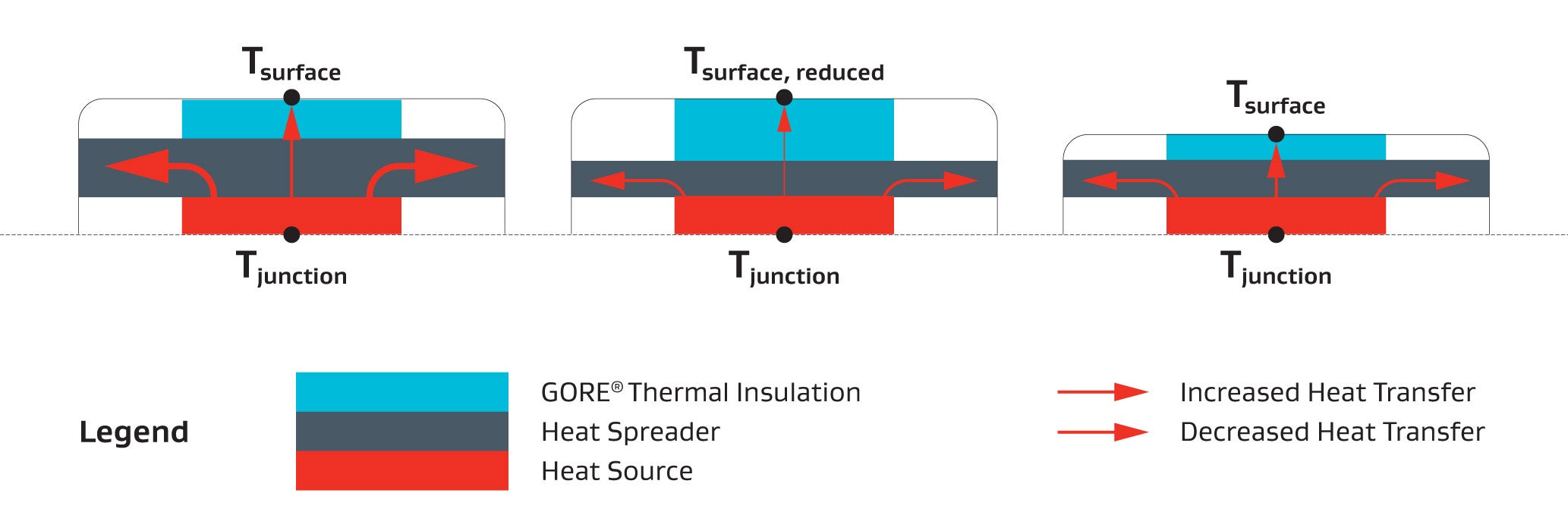

The Effect Insulation Has on Heat Transfer

This video demonstrates the effect insulation has on heat transfer. Watch how rapidly heat melts a crayon with and without GORE® Thermal Insulation.

GORE Thermal Insulation x DELL XPS 13

DELL uses GORE Thermal Insulation to improve performance and slim the design of its laptops.

Technical Information

Material Data*

Characteristic |

|

|

|

|

|

|

|---|---|---|---|---|---|---|

Insulation thickness availablea | 0.10 mm | 0.12 mm | 0.23 mm | 0.28 mm | 0.38 mm | 0.53 mm |

Adhesive encapsulation width (minimum)b | 1 mm | 1 mm | 1 mm | 1 mm | 1 mm | 1.5 mm |

Thermal conductivity (k)c | 0.021 W/m•K |

| 0.020 W/m•K |

|

|

|

Compression @ 100 kPa (14.5 psi) | 13% |

| 8% |

|

|

|

Specific heat capacityd | 1.8 J/g °C |

|

|

|

|

|

Bulk density | 0.37 g/cc |

|

|

|

|

|

Operating temperaturee | -40°C to 100 °C |

|

|

|

|

|

Protective cover film | Black PET |

|

|

|

|

|

Adhesive type | Acrylic |

|

|

|

|

|

RoHSf | Meets threshold requirements |

|

|

|

|

|

Max part size | 100 mm x 200 mm |

|

|

|

|

|

a Nominal thickness based on reported values of thickness of each component of the stack-up.

b Nominal minimum width.

c Nominal conductivity value based on a modified version of ASTM C518.

d Nominal heat capacity measured according to ASTM E2716 Method B at 75 °C.

e Alternate adhesives required to exceed 100 °C.

f To the best of our knowledge, the product listed above does not have any restricted substances above the maximum concentration values listed in RoHS Directive 2011/65/EU and meets the substance restrictions of Article 4 of RoHS Recast including Commission Delegated Directive 2015/863.

*All values are based on nominal characteristics and do not represent the specification and tolerance.

Also known as “Anisotropic Ratio,” this ratio characterizes heat dissipation:

KxyKz | kxy - Thermal conductivity in-plane divided by kz - Thermal conductivity through-plane |

Common heat spreader materials have an intrinsically high anisotropic ratio, which promotes heat to spread and move in-plane.

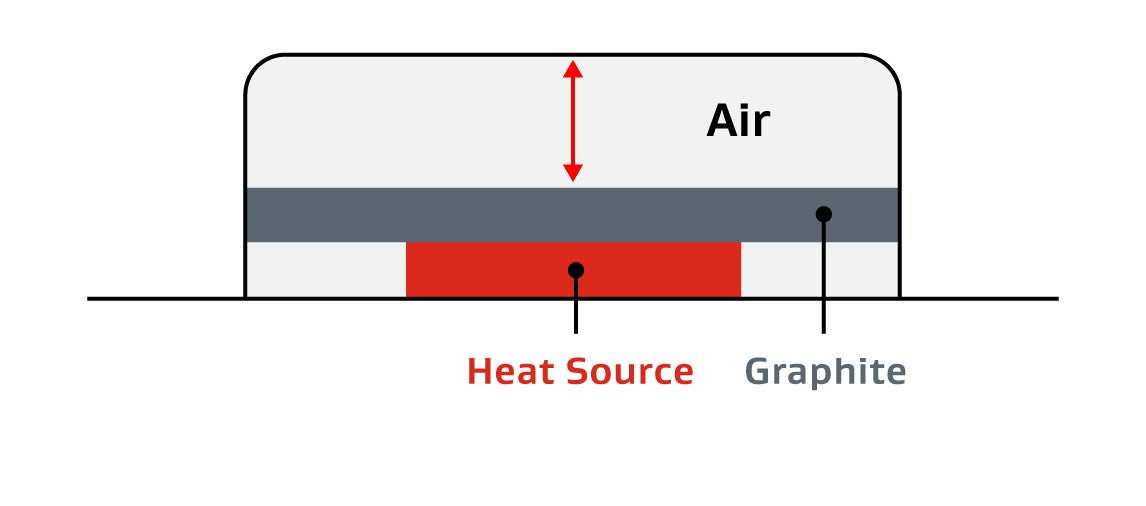

However, compared to insulators, these materials have a very high Kz , which allows heat to move through-plane and reach device surfaces. To compensate for spreaders' high Kz , thermal engineers often design air gaps (with low Kz) above spreaders.

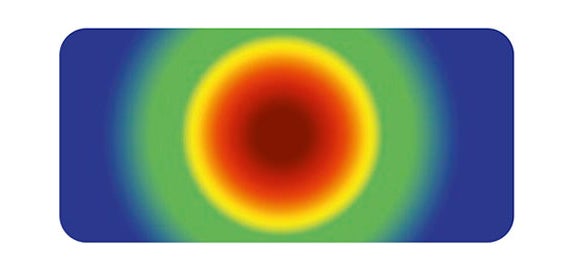

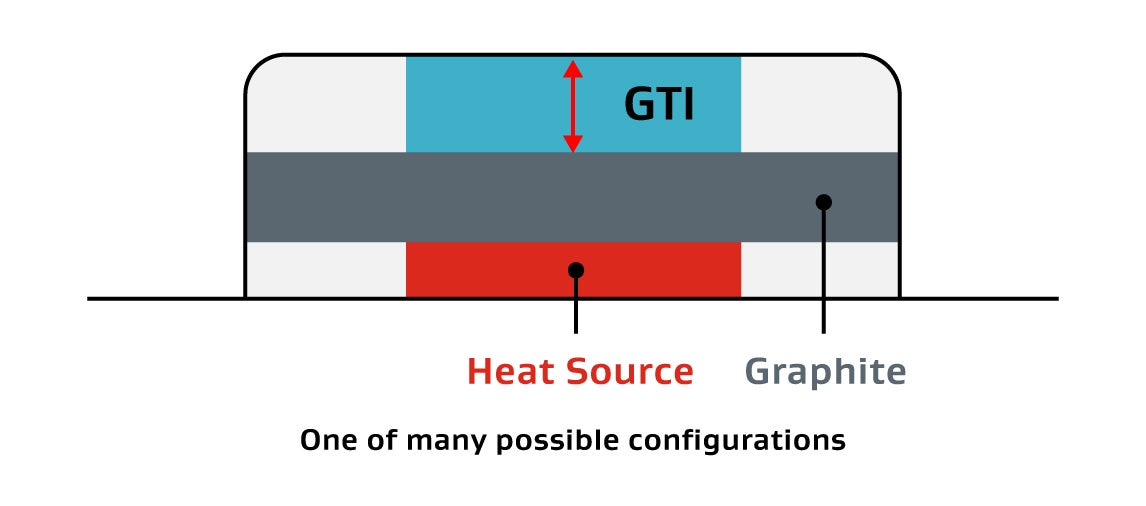

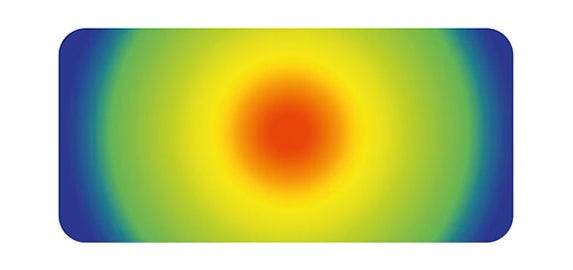

Comparison: Effectiveness of Thermal Spreading with and without GORE Thermal Insulation

GORE Thermal Insulation increases the designer’s ability to direct heat by enabling greater control of z-axis thermal conductivity. More control means superior spreading options and more design flexibility.

Combining GORE Thermal Insulation with graphite for example — one of many possible configurations — allows for more graphite to be included, as a thinner amount of insulation can be used to provide the same thermal resistance as a thicker air gap.

Added graphite capacity in the system allows for components to be utilized at higher power outputs, as the additional generated heat can be directed away from the component.

Basic Spreading

Graphite & Air

Side View - Thermal Solution

Top View - Hotspot

Enhanced Spreading

Graphite & GORE® Thermal Insulation (GTI)

Side View - Thermal Solution

Top View - Hotspot

Heat spreading effectiveness of a basic thermal design using graphite and air (left) compared to a thermal design using graphite and GORE Thermal Insulation (right). The basic thermal design fails to reduce hot spots because, while the heat is conducted through graphite in the xy-direction, it is also conducted in the z-direction of graphite, resulting in a hot spot.

Using GORE Thermal Insulation instead of an air gap reduces z-axis conductivity, increases the spreading ratio and reduces hot spots.

GORE Thermal Insulation contains aerogel particles suspended in a PTFE matrix to deliver conductivity lower than that of air. This thermal insulation material for electronics can be used to reduce hot spots by replacing air gaps. It can also be paired with graphite to enhance thermal spreading in-plane without increasing thermal transfer through-plane.

GORE Thermal Insulation is a compressible thermal insulation. With compression levels up to 13% under a 100 kPa load, it can be used for tolerance take-up or to assist with impact resistance. It also has the ability to adhere to curved or stepped surfaces without negatively affecting performance.

GORE Thermal Insulation is a thermal and electrical insulator. With thermal conductivity lower than that of air, this insulation is also an effective electrical insulator, with a volume resistivity > 10^15 ohm-cm.

The typical thermal conductivity of electrical insulators is low, in the range of 0.05 – 0.8 W/m-K 0.03-0.8 W/m·K. However,

GORE Thermal Insulation is far better, with conductivity as low as 0.020 W/m·K, while also delivering good electrical insulation.

Technology Expertise in Thermal Management for Mobile Devices

- High loading of aerogel to obtain low conductivity

- Consistent distribution of aerogel enables consistent conductivity

Consistent thickness across a range of thicknesses from 100-530 μm

All data points are from finished good parts of Gore and competitor (insulation + adhesives + cover films)

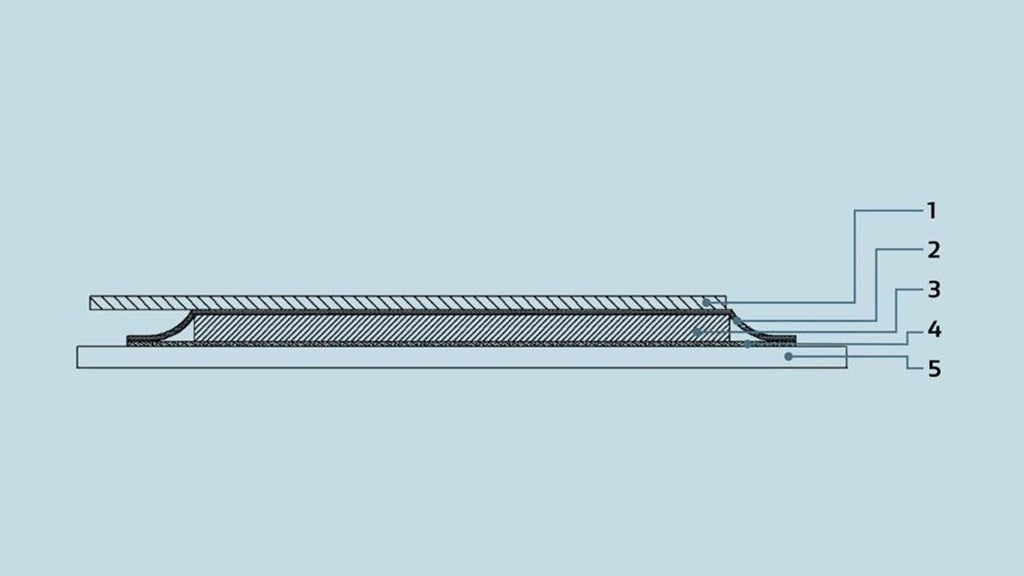

Gore Thermal Insulation cross section

- Pull Tab

- Protective Film

- GORE® Thermal Insulation

- Base Adhesive

- Base Liner

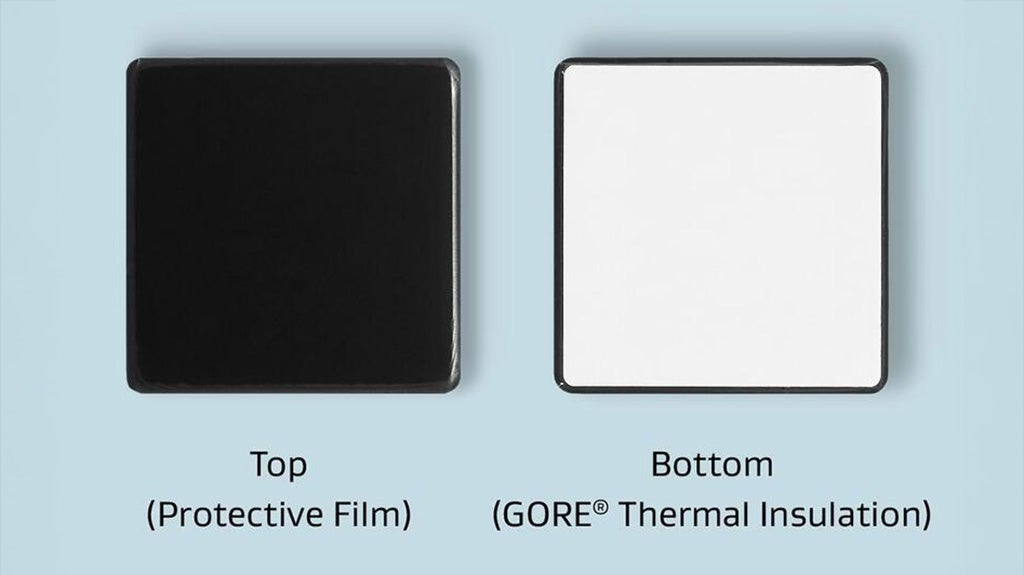

Gore Thermal Insulation surface images

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 410 506 7812

Have questions or unique requirements?

Our experts are here to guide you.