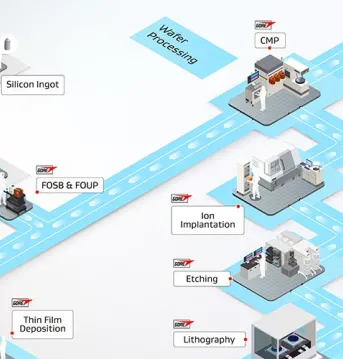

GORE® Trackless High Flex Cables for Semiconductor Production Equipment

Our light, self-supporting cables offer increased positioning accuracy at faster speeds, improved durability, easy install and cleaner operation in semiconductor production equipment.

Increase Throughput with a Simpler Trackless Cable Management System

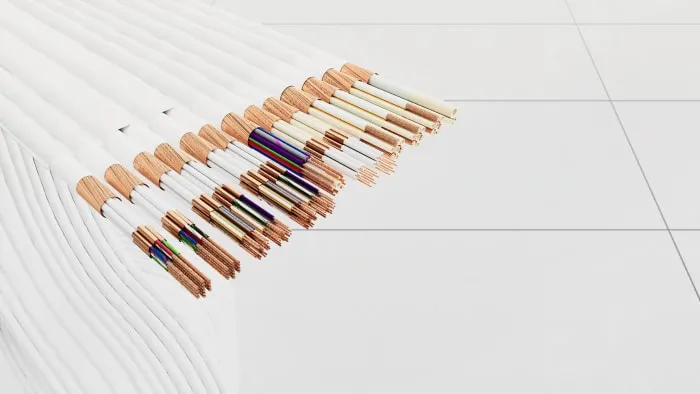

Offered with a standard or anti-static jacket, GORE® Trackless High Flex Cables help reduce overall system footprint, increase throughput and yield, decrease maintenance and reduce total costs. Our durable cables reduce particulation and prevent electrostatic discharge (ESD) events.

Technical Information

These values demonstrate the electrical, mechanical and environmental performance of GORE Trackless High Flex Cables for semiconductor production equipment in cleanroom and ESD-sensitive environments.

Elec. / Mech. / Environ. Property | Standard Version | Anti-Static Version |

|---|---|---|

| Maximum Acceleration g (m/sec2) | 4.0 (40) | 4.0 (40) |

| Speed m/sec | 4.0 | 4.0 |

| Surface Resistance Ohms (ASTM-D257) 45%, rH, 23°C | — | </= 2 x 109 |

| Typical Charge Decaya msec (DIN-EN 1149-5; 2008-04) 45% rH, 23°C | — | ≤ 4 |

| Voltage Buildupa V (PLFWI-2730 up to 1000 Cycles) | — | << 100 |

| Operating Relative Humidity rH % | 45 ± 15 | 45 ± 15 |

| Jacket Material | Expanded PTFE Composite | Expanded PTFE Composite with Non-Carbon-Based Dissipative Material Treatmentb |

| Jacket Color | White | White |

| Core Types | Signal, Power, Fiber Optic, Pneumatics | Signal, Power, Fiber Optic, Pneumatics |

| Maximum Self-Supporting Stroke Lengthc mm (in) | 1500 (60) | 1500 (60) |

| Overall Widthd mm (in) | Up to 105 (4.1) | Up to 105 (4.1) |

| Minimum Bend Radiusd mm (in) | 50 (2) | 50 (2) |

| Flex Life Cycles (BR. 50 mm up to 4G Accelerations) | > 10 million | > 10 million |

| Temperature Range °C | -40 to +80 | -40 to +80 |

| Cleanliness Classe (ISO14664-1) | 1 | 1 (Up to 1 Mio Flex Cycle) |

| Certificationsf | UL, CE | — |

| Particulationg % (ISO14664-1 / VDI Guideline 2083) | < 0.1 | < 0.1 |

a. Results may vary under different conditions. Test method details available upon request.

b. Details of Gore’s patent available at patents.justia.com/patent/9534159.

c. Baseplate required.

d. Standard configuration only. MBR can vary with specific configurations.

e. Based on Anti-ESD Trackless Cable, GKT-FTFH-01-A, Serial Number 14111802. Qualification report available upon request.

f. UL Style 21090: 80°C, pneumatic tubes are not UL recognized.

g. Details of the Fraunhofer Institute’s study available at gore.com/particulation.

The Fraunhofer Institute in Germany determined that GORE High Flex Flat Cables have < 0.1% probability of emitting particulates. They maintain the lowest particulation levels for repeated flexing in cleanroom environments.

Featured Content

Explore More

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Prefer to Call?

Have questions or unique requirements?

Our experts are here to guide you.

+1 800 626 7708

Have questions or unique requirements?

Our experts are here to guide you.