Press Release

GORE® EXCLUDER® Iliac Branch Endoprosthesis Gains Health Canada Approval

Posted April 28, 2016

W. L. Gore & Associates, Inc. (Gore) announced the Health Canada approval of the GORE® EXCLUDER® Iliac Branch Endoprosthesis (IBE), making it the most recent off-the-shelf aortic branch device approved in Canada for the endovascular treatment of common iliac artery aneurysms or aortoiliac aneurysms.

NEMA Ratings and What They Mean

Technical Information

A critical aspect of vent selection begins with defining the level of protection your application, device or housing requires.

IP ratings cannot be “converted” to NEMA ratings, since NEMA requires additional testing not included in IP. However, there are minimum NEMA ratings that will meet or exceed a given IP code.

What Quality Means, To Us and For You

Technical Information

At Gore, our commitment is to deliver products that meet our customers’ expectations and are fit for their intended end-use. We commit to every customer that “our products will do what we say they will do" — and we stand behind that promise with our worldwide resources, expertise, and quality processes.

PPAP (Production Part Approval Process) Overview

Technical Information

PPAP is integral to the IATF16949:2016 Quality System. It defines generic requirements for production part approval. It ensures that parts manufacturers, like Gore, document our capability to consistently meet your product specifications when manufacturing that product at quoted production levels.

BSS7230, BSS7238, BSS7239 Test Report: GORE® FireWire® Cables for Aircraft

Test Data, 34.58 KB

Test report prepared by Govmark for Gore part number RCN8652. The report outlines Gore's compliance to BSS7230 for Flammability, BSS7238 for Smoke Density, and BSS7239 for Toxicity.

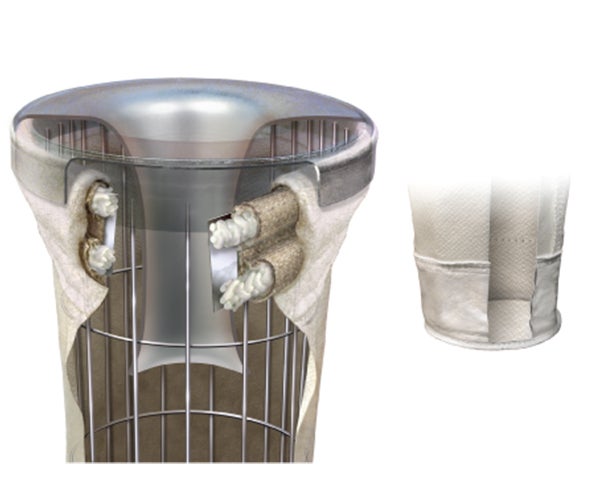

GORE® Industrial Baghouse Filters: Membrane Construction

Technical Information

To keep your system optimized we are constantly improving the performance of our membranes. Each new generation directly leads to increases in productivity. A wide variety of GORE® membranes and specially developed backing materials are available.

Bag life is now between 9 and 18 months, as opposed to the previous 2-4 months. Energy savings due to low DP is about $2,000/year. Emissions are virtually non-detectable with 0% opacity. Improved product recovery provided over $10,000/year of additional salable products. Less downtime and improved airflow equated to a production increase of over 10%.