Gore’s Microwave/RF Solutions Surpass U.S. Army Flight Qualifications for Critical Aircraft Survivability Equipment (ASE)

LANDENBERG, Pa (April 25, 2017) - W. L. Gore & Associates, Inc. (Gore) announced today that GORE-FLIGHT™ Microwave Assemblies and GORE® Microwave/RF Assemblies for military aerospace applications have successfully passed stringent U.S. Army flight qualifications on the MH-47 Rotorcraft. Gore provided a complex harness that included more than 100 of their rugged assemblies for the ALQ-211 SIRFC — a critical aircraft survivability system used by the 160th SOAR (Special Operations Aviation Regiment). Gore also provided a similar microwave/RF solution for ASE on the MH-60 Rotorcraft that is expected to pass U.S. Army flight qualifications in the next several months.

GORE-FLIGHT™ Microwave Assemblies are a lightweight, fit-and-forget solution that delivers the lowest insertion loss before and after installation, guaranteeing reliable performance for the life of your system.

Steve Blasey, Director of the Aviation Maintenance Support Office, said, "These guys jumped in and supported us when we were having some serious maintenance issues with these cables. We are impressed that we have yet to have a failure on a cable set that was routinely failing us. ASE is a mission requirement, and improved reliability equates to improved availability."

"It has been a great honor working with these elite warfighters," said Renee Burba, Product Line Manager for Gore's Microwave Assemblies. "My team and I are pleased that our solutions not only met but surpassed the high standards set forth by the U.S. Army for all of their products. We are also happy that our products met the Army's expectations and helped solve the issue with the alternative cables frequently failing in their ASE system."

Gore is also working with the U.S. Army to provide high-speed data interconnects for future APR-39 D(V) 2 Radar Warning Receivers on the Apache D model. Brian Tallman, Product Manager for Gore's North American Aerospace Team, said, "Future systems will require higher data rates that are more sensitive to signal integrity issues during routing and installation. The Army recognizes that providing electrical margins and installed performance requires new technologies to avoid solutions that add weight."

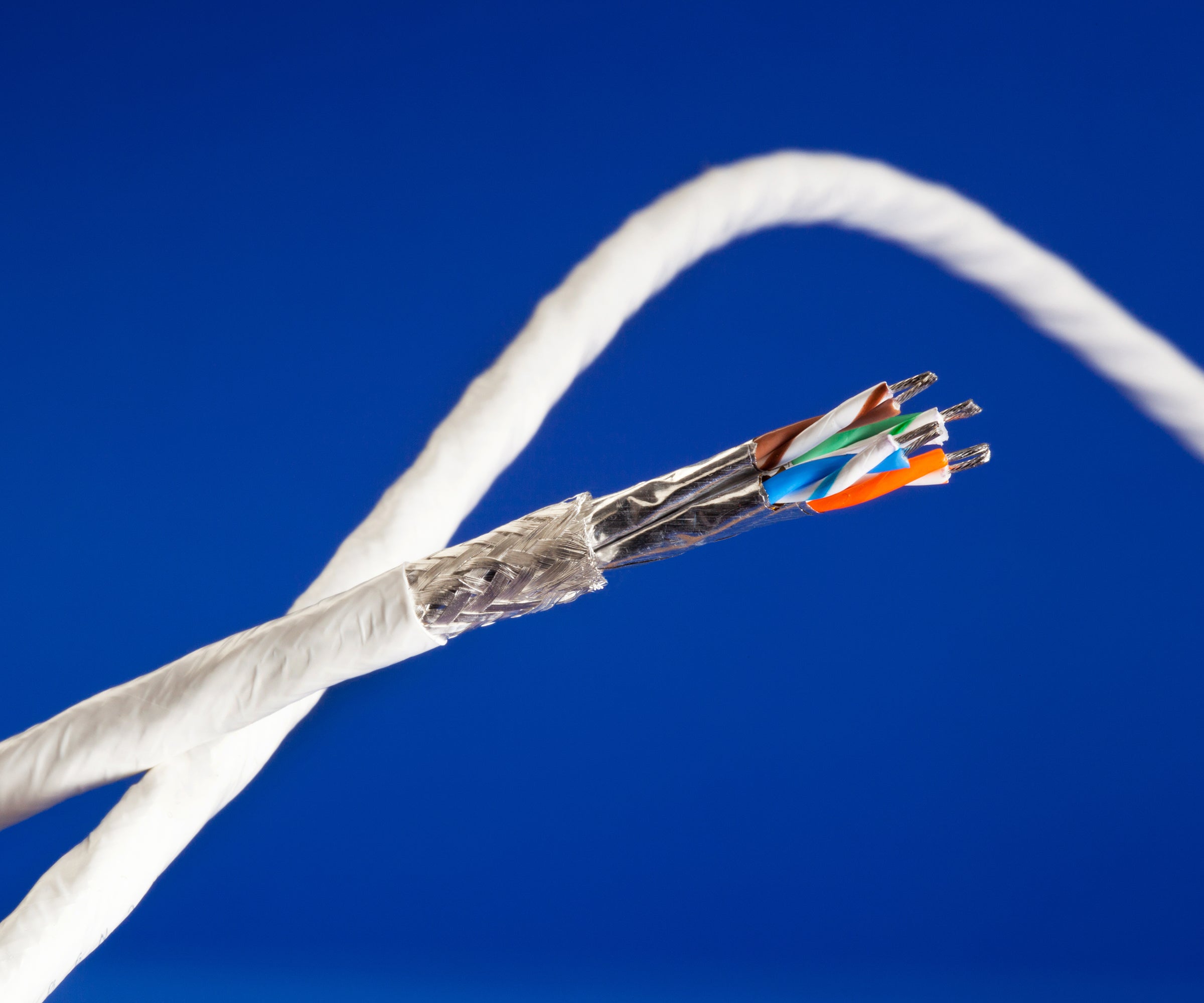

GORE® Aerospace Ethernet Cables deliver excellent electrical and mechanical performance in a small, lightweight, flexible and routable package that exceeds Cat6a requirements.

The 6 Series of GORE-FLIGHT™ Microwave Assemblies recently earned the highest recognition with a platinum award for product innovation by the Military & Aerospace Electronics 2016 Innovators Awards Program. Gore offers an extensive portfolio of advanced cables, cable assemblies, and materials designed specifically for the harsh conditions military personnel routinely encounter during critical missions. Products include microwave/RF assemblies, high data rate cables, high power delivery cables, aircraft sealants, and shielding materials that are significantly smaller and lighter weight yet more durable for long-lasting performance.

For more information about Gore’s entire line of products for military applications, visit gore.com or contact a Gore applications specialist at electronics.usa@wlgore.com.

About W. L. Gore & Associates, Inc.

Gore is a technology-driven company focused on discovery and product innovation. Well known for waterproof, breathable GORE-TEX® fabric, the company’s portfolio includes everything from high-performance fabrics and implantable medical devices to industrial manufacturing components and aerospace electronics. Founded in 1958 and headquartered in Newark, Delaware, Gore employs more than 10,000 associates with manufacturing facilities in the United States, Germany, the United Kingdom, Japan and China, and sales offices around the world. Gore is one of a select few companies to appear on all of the U.S. “100 Best Companies to Work For” lists since the rankings debuted in 1984. The company also appears regularly on similar lists around the world.

Media Contact

Gail Smith-Berry

+44 (0) 1382 569245

Contact by email