GORE® Automotive Vents for High-Voltage Applications

As various types of EVs become more popular, the internal structure of the vehicles is becoming increasingly high voltage. This higher voltage requires regular maintenance of parts, cleanliness control to prevent short circuits, and higher levels of quality control.

GORE® Automotive Vents Super High Airflow Series

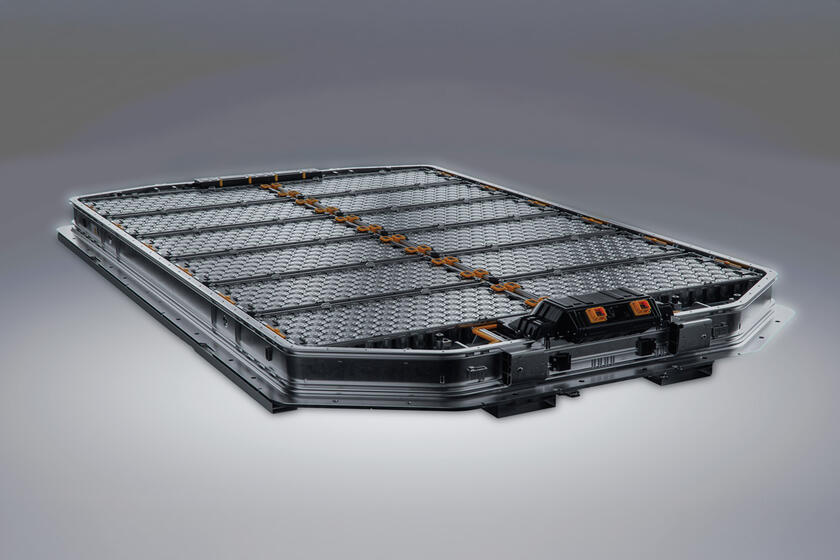

Increase safety of Li-ion batteries for EVs and lower total cost

Feature

- 3x the minimum airflow of our High Airflow PolyVent AMF300070

- Same compact dimensions

- Uncompromising water protection (IPX7)

Application

GORE® Automotive Vents for High-Severity Application

Preventing vent-related failures in high-severity applications for electric vehicles.

Feature

- Designed for safety-critical applications with DFMEA severity level 9 or 10, including battery packs and ADAS.

- IATF 16949 quality management and support the IATF safe launch standard.

- Compliant with ISO 26262, they are vital for meeting automotive safety standards in high-severity applications for electric vehicles.

Application

GORE® Automotive Vents Screw-in Series

Screw-in structure contributes to greater design freedom

Feature

- Can be removed for component maintenance

- UL94 V-0 rated housing and o-ring

- IPx9k rating — no protective wall needed

- For 3.0 mm housing walls with a counter nut, or 5.0 mm walls without a counter nut.

Application

GORE® Automotive Vents Clean Protected Series

New way to achieve and assure part cleanliness for EV high-voltage electronics and ADAS applications.

Feature

- Independent third-party Cleanliness Certificate

- Traceability and laser marking

- UL Flammability safety rating

Application

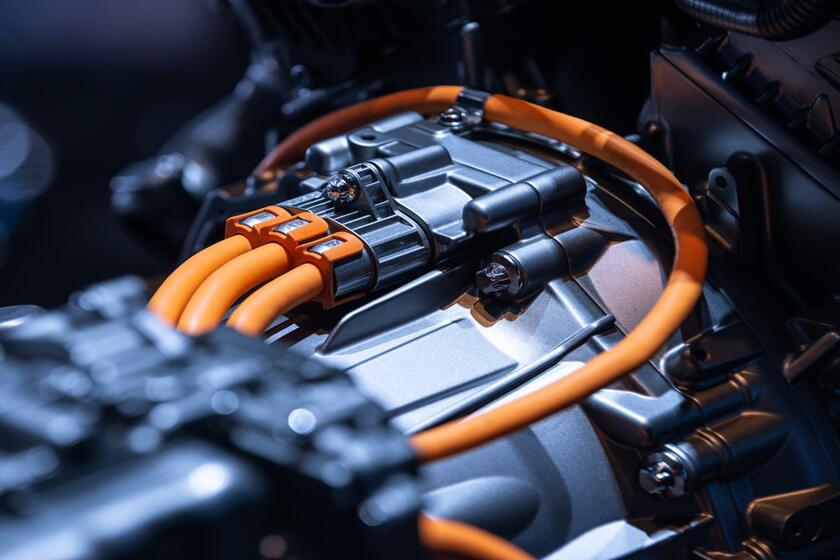

GORE® Automotive Vents for Power Train

Protects e-drivetrain components from damaging contaminants

Feature

Common

- Suitable for applications involving exposure to oil aerosols, where traditional vents fail.

- Compact, low-profile construction enables more design options, especially for space-constrained e-drivetrain and e-motor applications.

Direct-fit

- Direct-fit (vent mounted directly into component housing) can streamline sourcing, supply and assembly efforts.

- Easy snap-fit integration to housing.

Tube-mount

- Tube-mount “distances” vent from potential exposure to high temperatures or lubricants.

- Tube format enables more flexibility in routing, especially for traditional powertrain components.

- Easy integration into existing applications; vent replacement, if required, is easy.