GORE® GFO® Fiber

The right packing for reliability and savings.

Contact Us

United States

+1 800 455 2854

Australia

+61 2 9473 6800

Brazil

+55 11 5502 7800

China

+8621 5172 8299

France

+33 1 56 95 65 65

Germany

+49 89 4612 2215

Hong Kong

+852 2622 9622

India

+91 22 67687000

Italy

+39 045 6 20 92 50

Japan

+81 3 6746 2600

Korea

+82 2 393 3411

Netherlands

+31 13 507 47 00

Poland

+48 22 6 45 15 37

Scandinavia

+46 31 706 78 00

Singapore

+65 6733 2882

South Africa

+27 71 467 7710

Spain

+34 93 4 80 69 00

United Arab Emirates

+971 2 5089444

United Kingdom

+44 1506 46 01 23

Overview

Plant operators often are not aware that similar looking compression packings do not perform the same, leading to significant hidden costs. While procurement has a tight hold on the upfront packing cost, the greater cost takes place in operation.

Packings with 100% GORE GFO Fiber can provide maintenance engineers with consistently high performance general service packing for wide application and use, including sealing shafts on high-speed pumps, mixers, agitators or any other equipment with rotating or reciprocating shafts. They don’t become hard or brittle, are temperature and chemically tolerant and easy to install and remove. Plant operators can be assured that packings with 100% GORE GFO Fiber will consistently deliver the trouble-free performance they need.

What makes the GORE GFO Fiber Unique?

A sustainable solution

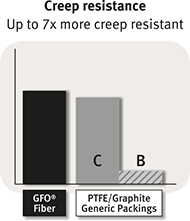

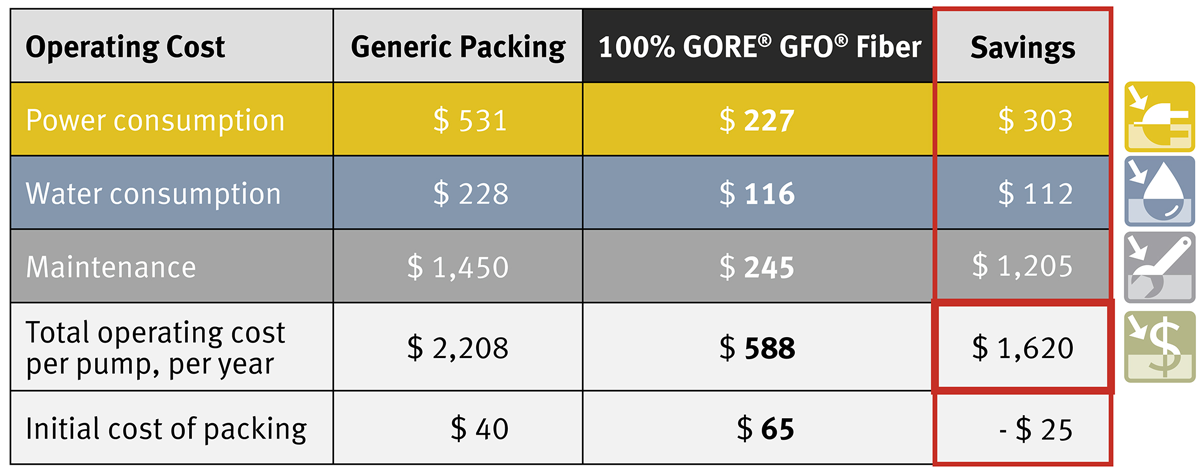

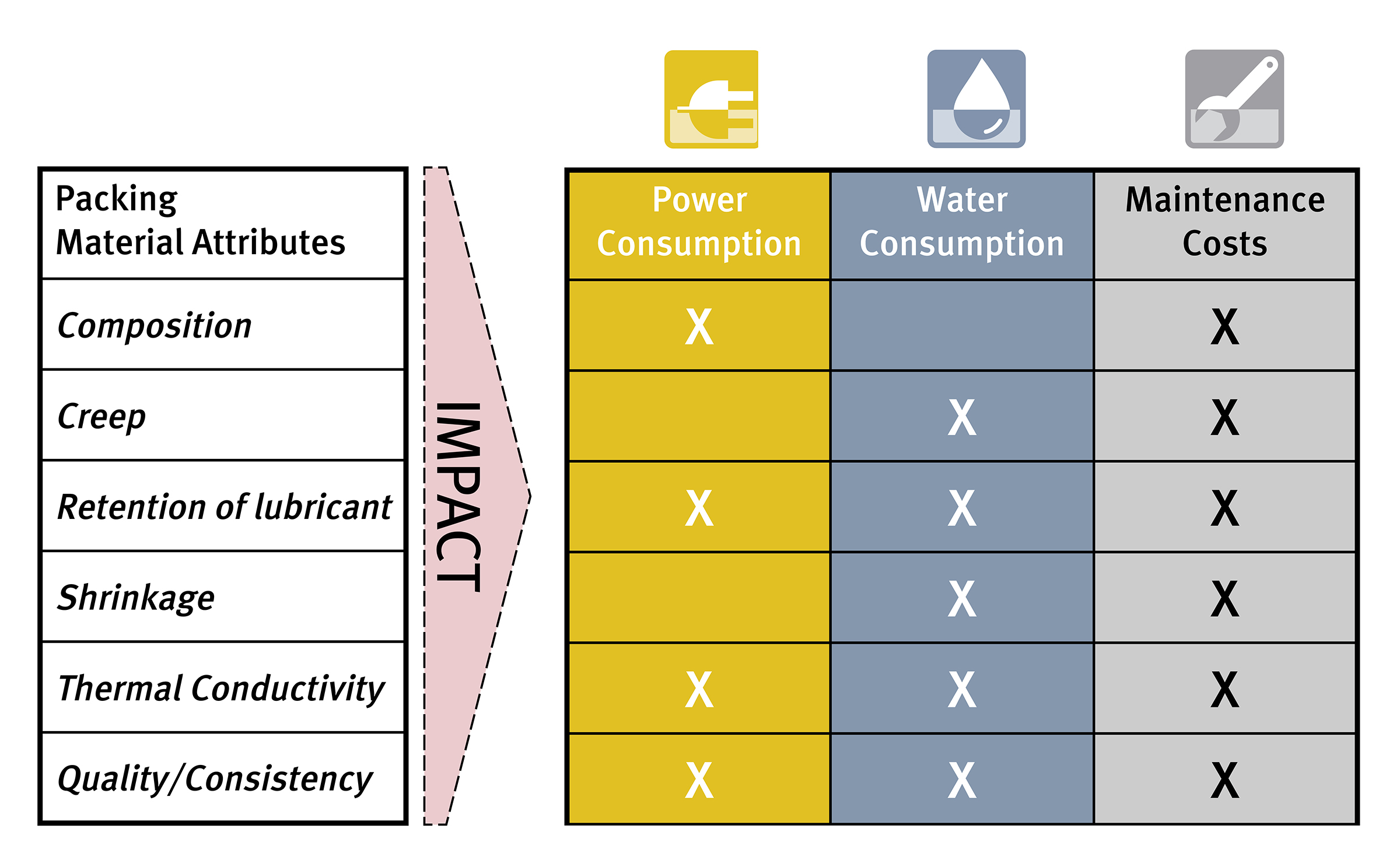

Gore has tested packing made of 100% GORE GFO Fiber alongside generic graphite/PTFE packings.

Packings made of 100% GORE GFO Fiber achieve better results for all attributes. The differences in performance for each generic packing will have an impact on the operational costs. The example below shows an estimate of the savings that can be made by using packing made of 100% GORE GFO Fiber.

Based on calculations for a 100 psi (6.9 bar) pump, 2 inch shaft (50 mm); Drip rate 25,000 gallons (94.6 m3)/ year; Packing = $40; Replacement of packing = 3 times per year; kWh = $0.12

Outperforms generic PTFE/graphite packings

This video clip shows the leakage rate difference between a packing made with 100% GORE GFO Fiber versus a generic PTFE/graphite packing.

Leakage differences between compression packings for centrifugal pumps

How packing made from 100% GORE GFO Fiber outperforms other packings.

Quality assured

Many PTFE/graphite packings are available in the market. While they may all look the same, it is worth noting that there are huge inconsistencies in the actual product quality and performance of many of the packing solutions offered. The installation of these products can increase operating costs (power, water, maintenance) and risk of premature failure as well as unscheduled shutdowns. Such problems can cost a lot of time and money.

To help overcome these challenges, Gore created the Seal of Assurance Program. Through a global network of authorized braiders, this program ensures that every fiber used to braid the packing is a GORE GFO Fiber. Look for the 100% GFO seal on the box and print right on the packing –— it’s the only packing that is identified this way!

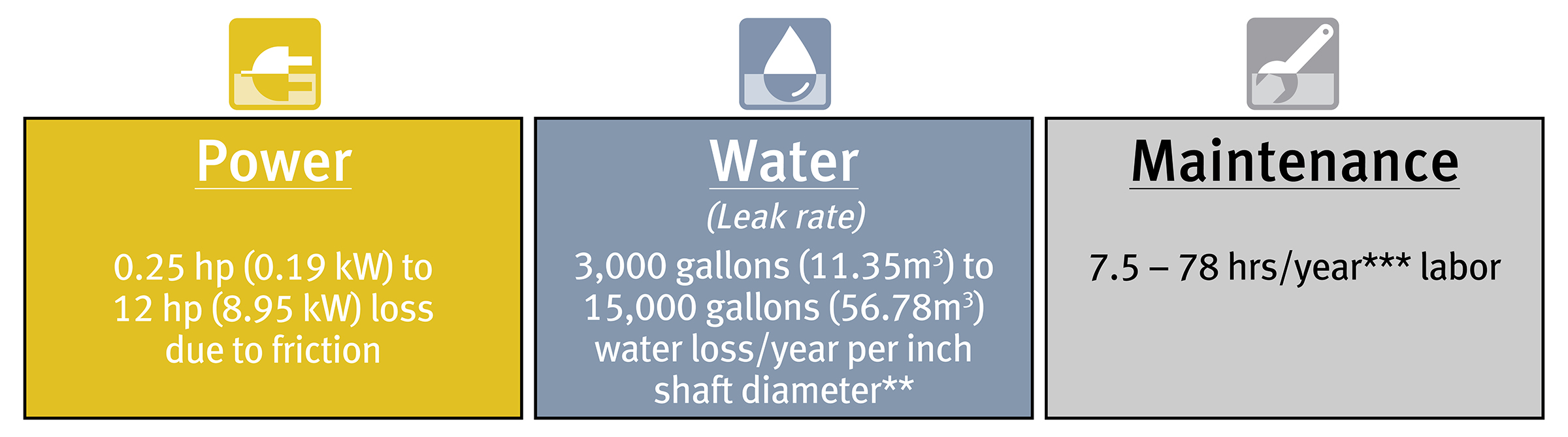

Hidden Costs of Packing

Compression packing — plant experience

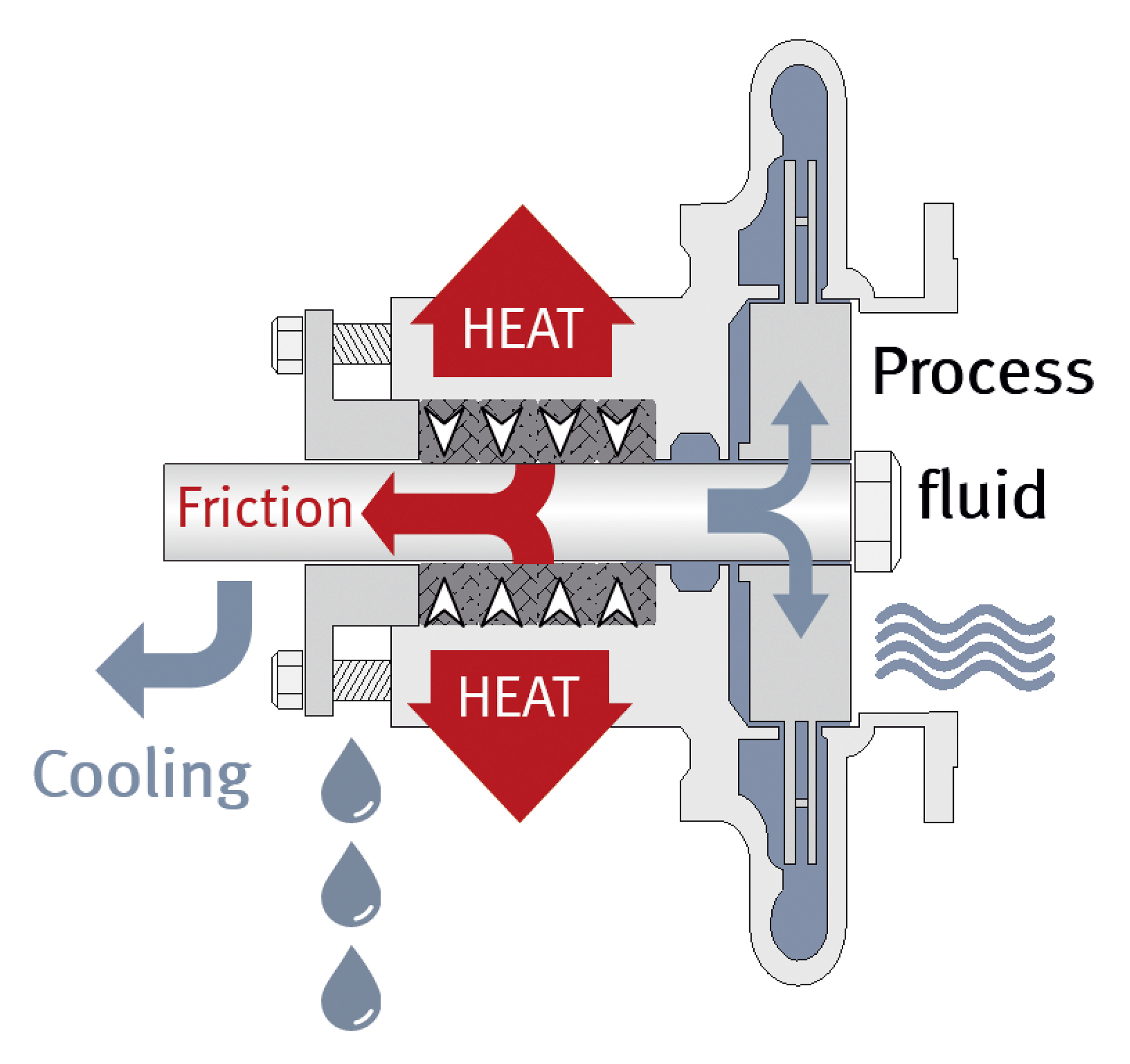

Compression packing has been around since the beginning of the industrial revolution. It is still used extensively today in equipment where plant operators understand the advantages of managing the warning signs of a degrading pump packing versus sudden failure mode of mechanical seals. Experienced operators know to watch out for telltale signs of packing degradation, such as an increase in flush water use, the need for gland follower adjustments, a hot running or even a smoking pump.

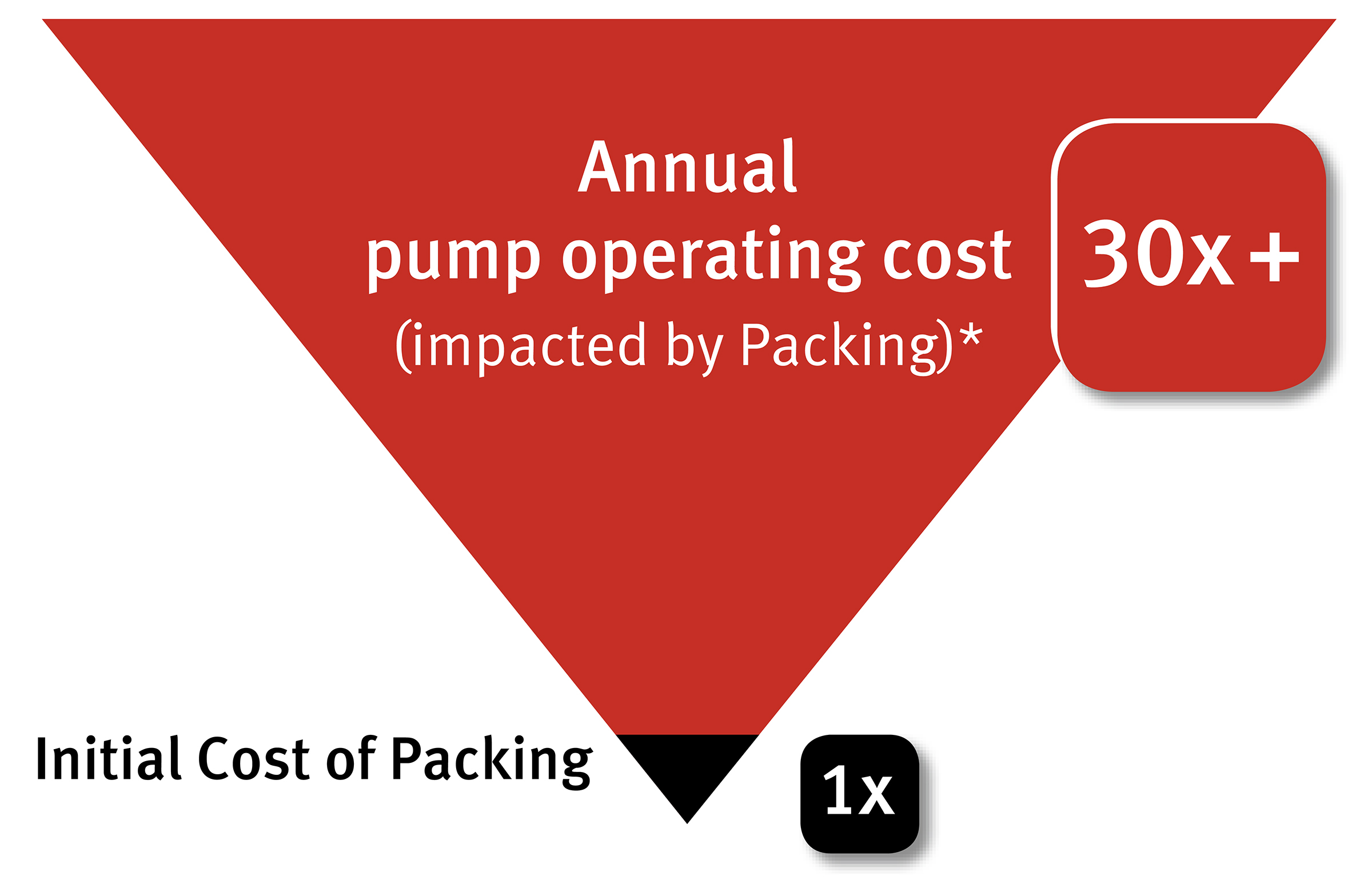

Hidden Costs

What is less known is that the operational costs of keeping a pump running through these conditions versus the original packing cost is estimated to be 30 times greater!* While procurement has a tight hold on the upfront packing cost, the real cost takes place in operation.

*Based on calculations for a 100 psi (6.9 bar) pump, 2 inch shaft (50 mm); Drip rate 25,000 gallons (94.6 m3) / year; Packing = $40; Replacement of packing = 3 times per year; kWh = $0.12

While sealing off the process fluid from escaping along the pump shaft, packing acts like a brake in a car producing friction and heat. An operator must take care to avoid overtightening the packing while disallowing media or excessive flush water leakage. Usually an operator will opt for a bit more leakage when one more gland adjustment risks seizing up the pump and shutdown. But if early warning signs are missed on a degrading packing then increased maintenance is inevitable.

Less visible throughout the process are the effects of the material’s friction factor which has a direct impact on power and thus on the cost of operating the pump.

Avoidable waste

Despite these operational losses which have been hidden in plain view for decades, the industry has so far failed to tackle these avoidable wastes. A typical pump loses up to 39,000 kilowatt-hours which is enough to power 10 homes annually. The same pump will send 15,000 gallons (56.78m3) of water down the drain per year which is a similar volume of water contained in an average sized swimming pool.

Material attributes of packing affect pump performance

A smart solution is to make a strategic choice in compression packing based on material attributes.

Over the years the industry has found that PTFE graphite packings perform among the best at balancing these competing dynamics. However, PTFE graphite packings vary in degree of quality and performance.

Eliminate the hidden costs in your facility

Packings made of 100% GORE GFO Fiber achieve better results for all these attributes. Contact Gore for an estimate of the operational savings your plant will recover using GORE GFO Fiber.

Technical Specifications

| Temperature Range | -240°C to +288°C (-400°F to +550°F) |

|---|---|

| Chemical Resistance | Chemically inert, with few exceptions, over the entire 0-14 pH range. |

| Stability | Able to withstand shaft speeds to 4,300 feet per minute (21.8 m/s). |

Braid Density

The yield figures below are representative of satisfactory braided packing made of 100% GORE GFO Fiber. The data serves as a working guideline only and not as a minimum quality standard.

| Braided Packing Cross Section | Yield | ||

|---|---|---|---|

| in | mm | ft/lb | m/kg |

| 1/8 | 3.18 | 80.00 | 53.64 |

| 3/16 | 4.76 | 38.00 | 25.48 |

| 1/4 | 6.35 | 23.00 | 15.42 |

| 5/16 | 7.94 | 15.00 | 10.06 |

| 3/8 | 9.50 | 11.00 | 7.38 |

| 7/16 | 11.11 | 8.00 | 5.36 |

| 1/2 | 12.70 | 6.00 | 4.02 |

| 9/16 | 14.29 | 5.00 | 3.35 |

| 5/8 | 15.88 | 4.00 | 2.68 |

| 11/16 | 17.46 | 3.20 | 2.14 |

| 3/4 | 19.05 | 2.80 | 1.88 |

| 7/8 | 22.26 | 2.00 | 1.34 |

| 1 | 25.40 | 1.50 | 1.00 |

Braid Dimensional Tolerances

Another significant factor affecting braided packing performance is the degree to which it is properly sized. Calendaring braid and die-forming rings are two effective ways that the manufacturer can produce packing that closely adheres to dimensional specifications. The Fluid Sealing Association recommends the following tolerances.

| Cross Section | Tolerance |

|---|---|

| To 1/4 in | +/- 1/64 in |

| To 6 mm | +/- 0.4 mm |

| 1/4 in to 1 in | +/- 1/32 in |

| 6 mm to 25 mm | +/- 0.8 mm |

| Greater than 1 in | +/- 1/16 in |

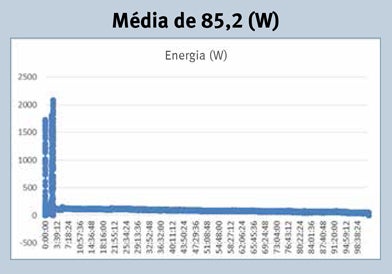

Test Data

CETIM EN 16752 Test Results

Cetim has performed testing on packing made of 100% GORE GFO Fiber using the EN 16752 "Centrifugal pumps – Test procedure for seal packing."

Test Protocol

- Ambient temperature

- Test medium: clean water

- 50 mm shaft diameter, 1500 & 3000 rpm

- Pressure: steady 0.6 MPa

- Loading: After 2 hours 1.8 kN, <1.5 kN 2nd & subsequent adjustments to 1.6–1.8 kN

Shaft Leak Rate

After initial break in stabilization, 3000 rpm.

Power Consumption

After initial break in stabilization, 3000 rpm.

More information on the Cetim test procedure can be found here.

Installation

Please view the "Pump and Valve Packing Installation Procedures" from the Fluid Sealing Association and the European Sealing Association e.V. for more information.

Certification Information

Safety Datasheets (SDS)

GORE® GFO® Fiber products meet the definition of an article; therefore, a Material Safety Data Sheet (MSDS) or Safety Data Sheet (SDS) is not required. However, for your convenience, a Product Safety Sheet, which details the intended use and proper handling of our articles, is provided.

Gore Quality Management System

The Gore Sealant Technologies Quality Management System is certified in accordance with ISO 9001.

Resources

Energy Efficiency of Compression Packings — Pump & Systems, August 2015

Industry Articles, 345.11 KB

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Follow GORE® GFO® Fiber