Article: Filters for NESHAP compliance

Industry Articles, 2.2 MB

In a four page article, Chris Polizzi, W. L. Gore & Associates, USA, addresses how the implications of the National Emissions Standards for Hazardous Air Pollutants (NESHAP) in the USA are far reaching in their targeting to reduce emissions from cement plants to unprecedented lower levels.

A R THOMSON GROUP

+1 902 468 9120

Stop by our booths 133 & 134 to check out our broad portfolio of proven aerospace cables and materials approved for use on multiple military aircraft, including the F-16

W. L. Gore & Associates, Inc. announced the acquisition of Pipeline Medical Technologies, Inc., a privately held medical technology company focused on advancing chordal repair for degenerative mitral regurgitation (DMR) via a transcatheter procedure.

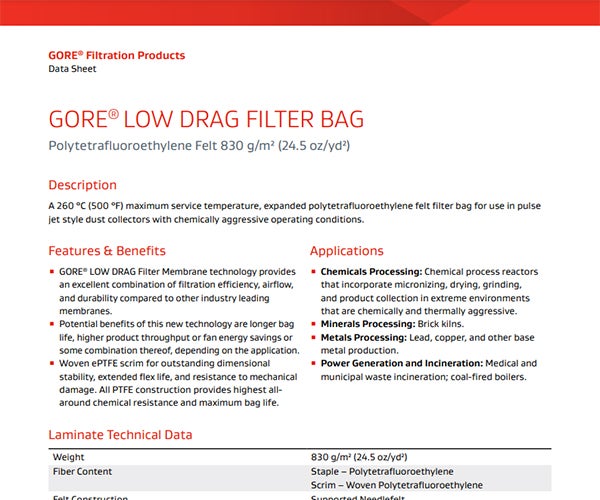

Data Sheet: GORE® LOW DRAG FILTER BAG 8378 PTFE Felt 830 g/m² (24.5 oz/yd2)

Data Sheets, 45.66 KB

A 260 °C (500 °F) maximum service temperature, expanded polytetrafluoroethylene felt filter bag for use in pulse jet style dust collectors with chemically aggressive operating conditions.

Preview GORE® Aerospace Cables and Materials Approved for Use on the F-16 at 2018 TCG Worldwide Review (WWR)

Ogden, Utah

F-16 Part Number Listing for Gore’s Defense Solutions

Part Number Information, 225.48 KB

Approved for use on the F-16 defense aircraft and trusted by the armed forces, solutions from W. L. Gore & Associates are available in microwave assemblies and high-speed data cables. Get National Stock Numbers (NSNs), CAGE codes and specifications.

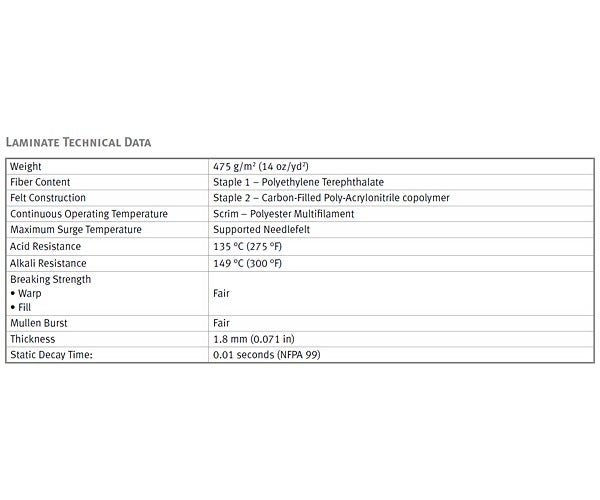

Data Sheet: Anti-Static Polyester Felt 475 g/m2 (14 oz/yd2)

Data Sheets, 107.95 KB

A 135 °C (275 °F) maximum service temperature, stayed-polyester felt filter cartridge for use in pulse jet style dust collectors where high differential pressure and high cleaning pressures are required due to aggressive dust loading.

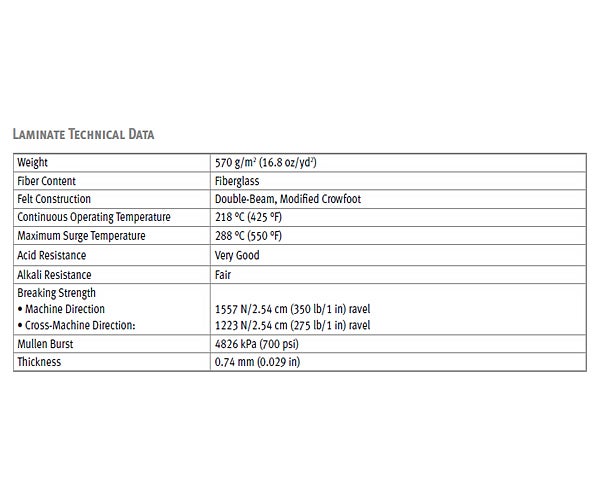

Data Sheet: Fiberglass Fabric Coated with Polytetrafluoroethylene 570 g/m2 (16.8 oz/yd2)

Data Sheets, 72.14 KB

A 218 °C (425 °F) maximum service temperature, stayed-polytetrafluoroethylene fiberglass fabric filter cartridge for use in pulse jet style dust collectors where high differential pressure and high cleaning pressures are required due to aggressive dust loading.