Case Study: Steel plant, South Carolina — GORE® LOW DRAG Filter Bags optimize operating efficiency while meeting regulatory compliance

Case Studies, United States

Steel plant producers must balance productivity with emissions control. Thanks to the use of GORE® LOW DRAG Filter Bags, a steel recycling plant in South Carolina has improved its overall operating efficiency, with no adverse effects to its regulatory compliance.

Challenge

Steel plant producers must balance productivity with emissions control. At a steel recycling plant in South Carolina, where two fans and 2,880 GORE® Standard Membrane Filter Bags were in place, the operations team struggled with dust cake buildup in its filter bags even after cleaning. As a result, volume plateaued at 758,000 ACFM. The plant looked to Gore, its longtime partner, for a solution that would improve the filter bags’ cleanability and increase system volume — without increasing overall emissions.

Solution

Gore recommended the installation of GORE LOW DRAG Filter Bags, an ePTFE laminate filtration solution that acts as a true surface filter in steel production. The key to the bags' effectiveness is a new class of membranes, which promote a 10–15% increase in airflow compared to standard filter bags. While other bags may get "clogged" over time, this increase in airflow allows GORE LOW DRAG Filter Bags to continually clean well and reduce pressure drop in the baghouse. Gore installed 2,800 filter bags — fewer than were previously installed — with no other changes needed to operations.

Result

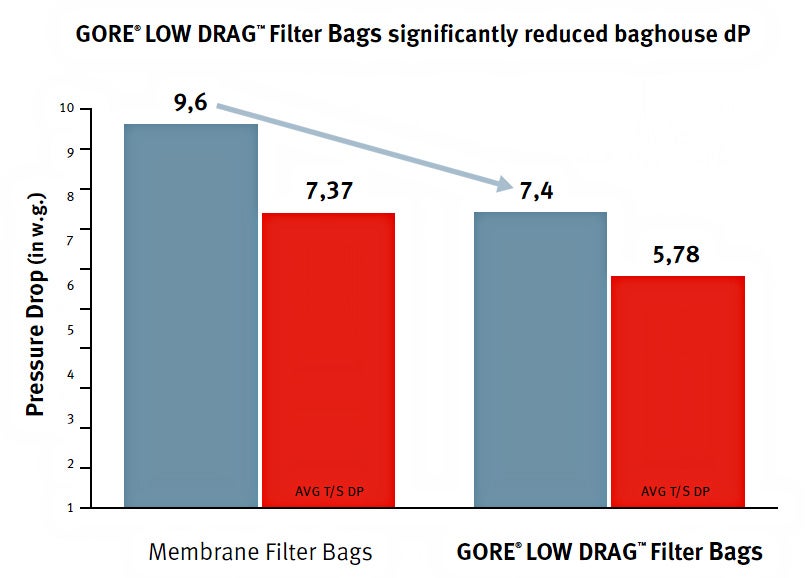

The updates delivered results as hoped: From day one, the new GORE LOW DRAG Filter Bags cleaned well. With this improvement in place, the baghouse dP reduced from 9.6" w.g. to 7.4" w.g. The ACFM average increased from 758,000 to 800,000, with a still greater increase to 1,000,000 ACFM possible. The operations team has seen an improved draft in the meltshop, and not only have emissions not increased, they have actually decreased. Encouraged by these optimizations, the operations team plans to reduce its use of sonic horns as a supplemental method of cleaning the filter bags. Overall, the plant has improved its operating efficiency, with no adverse effects to its regulatory compliance.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.