Data Sheet: Anti-Static Polyester Felt 475 g/m2 (14 oz/yd2)

Data Sheets, United States

A 135 °C (275 °F) maximum service temperature, stayed-polyester felt filter cartridge for use in pulse jet style dust collectors where high differential pressure and high cleaning pressures are required due to aggressive dust loading.

Features and Benefits

- Patented GORE™ High Durability membrane technology provides an excellent combination of filtration efficiency, airflow, and durability.

- Polyester fibers provide good all-around chemical resistance, especially in applications operated below 79°C (175°F).

- Carbon-filled poly-acrylonitrile copolymer fibers provide static dissipation (passes NFPA-99 Static Decay Test).

- Available in top, bottom, and horizontal loading configurations. Withstands pressure drop up to 6.2 kPa (25 inches water gauge).

- Special multifilament scrim design provides excellent dimensional stability and resistance to mechanical damage over the life of the filter.

Applications

- Chemicals Processing: Dryers, bin vents, and nuisance dust collectors in pigment, plastic, and catalyst industries.

- Minerals Processing: Coal mill collectors, finish mills, raw mills, bulk pneumatic conveying, and bin vent dust collectors.

- Metals Processing: Process venting and material handling dust collectors for pulverized coal.

- Power Generation and Incineration: Material handling for coal and limestone.

Technical Specifications

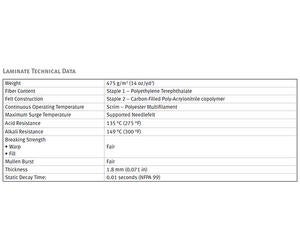

| Weight | 475 g/m2 (14 oz/yd2 |

| Fiber Content | Staple 1 – Polyethylene Terephthalate Staple 2 – Carbon-Filled Poly-Acrylonitrile copolymer Scrim – Polyester Multifilament |

| Felt Construction | Supported Needlefelt |

| Continuous Operating Temperature | 135 °C (275 °F) |

| Maximum Surge Temperature | 149 °C (300 °F) |

| Acid Resistance | Fair |

| Alkali Resistance | Fair |

Breaking Strength

|

|

| Mullen Burst | 4481 kPa (650 psi) |

| Thickness | 1.8 mm (0.071 in) |

| Static Decay Time | 0.01 seconds (NFPA 99) |

Note: All data expressed as typical values. This technical data is subject to change. Please contact W. L. Gore & Associates, Inc., directly to confirm current information.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.