GORE® USB Cables for Civil Aircraft

Our sturdy cable bundles deliver non-stop signal transmission for instant data uploads/downloads in cockpits and cabins while supporting the latest power management systems for portable electronic devices. They continue to meet the industry’s requirements for higher data rate cables that can survive extreme environments.

Contact Us

+1 800 626 7708

Germany

+49 9144 6010

+49 9144 6816 (fax)

UK

+44 1382 56 1511

+44 1382 56 1007 (fax)

Italy

+39 045 6209 209

+39 045 6209 165 (fax)

France

+33 1 5695 6565

+33 1 5695 6401 (fax)

Spain

+34 93 480 6900

+34 93 373 7850 (fax)

Sweden

+46 31 7067800

+46 31 864226 (fax)

China (Beijing)

+86 10 5707 4999

+86 10 5707 4900 (fax)

China (Shanghai)

+86 21 5172 8299

+86 21 6247 9199 (fax)

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Japan

+81 3 6746 2582

+81 3 6746 2571 (fax)

Overview

Passengers expect to download IFE content and charge their devices quickly and easily on their portable devices when traveling. Pilots expect to receive necessary data in the cockpit. So aircraft cables need to upload/download content and charge devices as fast as possible.

Added Durability for Lifetime Performance

GORE USB Cables in 2.0 and 3.1 versions equally deliver non-stop signal transmission up to 10 Gb ensuring high volumes of content are uploaded and downloaded in time. Our cable bundles also support the latest power management systems so passengers and flight crews can charge their portable electronic devices quickly and easily. Just as important, they withstand the harshest aircraft environments because of the added durability in the construction that provides enhanced protection for a long lifecycle.

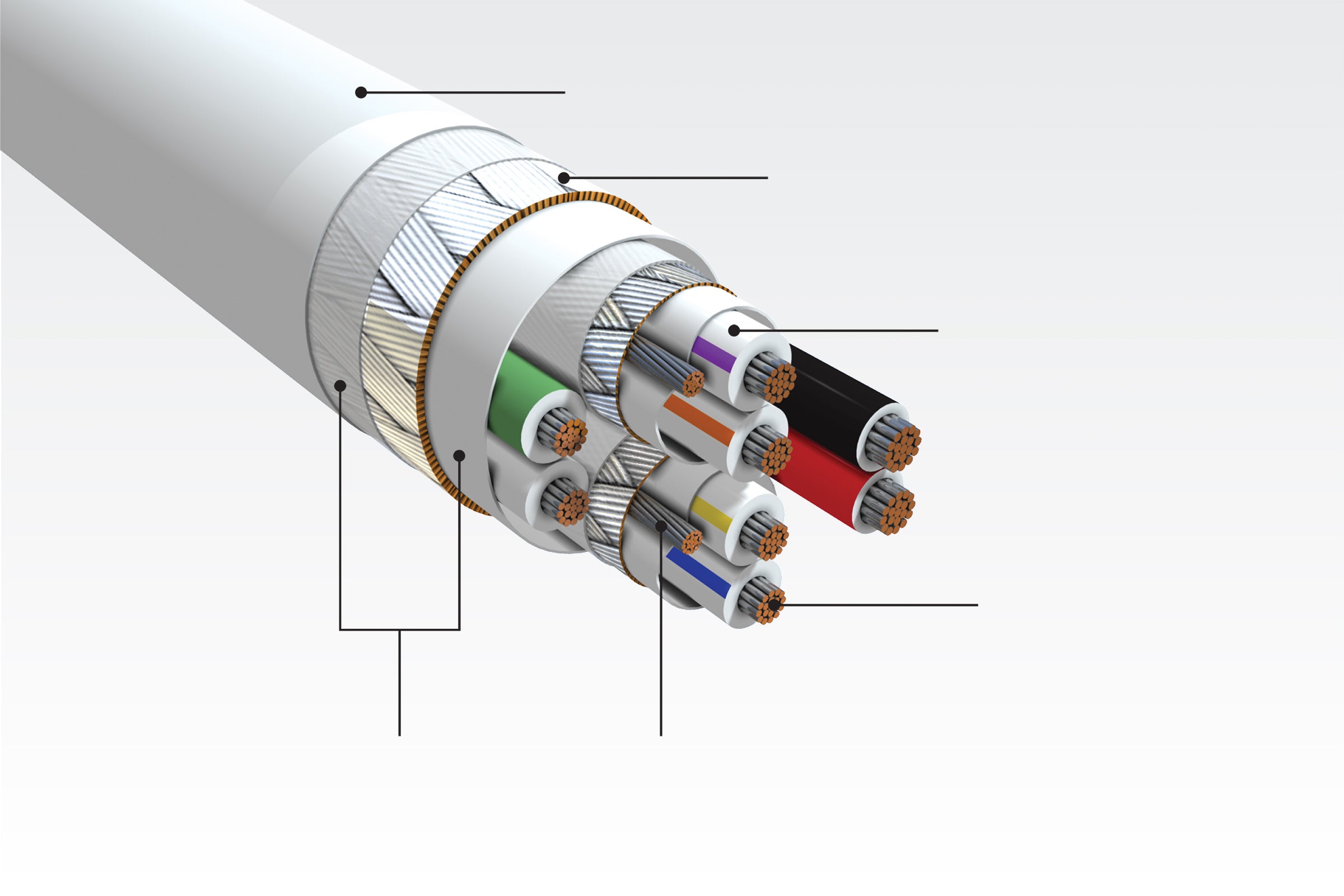

Sturdy bundle design of GORE USB Cables

Applications

GORE USB Cables are engineered to perform reliably in a variety of aircraft applications, including:

- content loading

- data transfer

- digital video systems

- electronic flight bag (EFB)

- portable electronic devices

- power remote devices

If you have any questions or to discuss your specific application needs, please contact a Gore representative.

Benefits

GORE USB Cables provide aircraft system architects and engineers with many benefits that improve electrical and mechanical performance such as:

- non-stop signals for high-speed data transmission up to 10 Gb

- ensure high volumes of content are uploaded/downloaded instantly

- support latest power management systems to charge devices quickly

- sturdy bundle design withstands extreme environments for long lifecycle

- compatible with variety of high-speed aerospace connector systems/backshells

- selected pre-qualified samples with short lead times for prototyping and evaluation

- low technical risk based on validated product performance in real-world conditions

For more information about the benefits of our cables, please contact a Gore representative.

Properties

These values demonstrate the electrical, mechanical and environmental performance of GORE USB Cables.

Electrical

| Electrical Property | Value |

|---|---|

| Standard Impedance (Ohms) High-Speed Pairs Low-Speed Pairs |

90 ± 5 90 ± 10 |

| Typical Operating Voltage (V) | < 15 |

| Nominal Velocity of Propagation (%) | 80 |

| Nominal Time Delay ns/m (ns/ft) | 4.07 (1.24) |

| Capacitance pF/m (pF/ft) | 50.0 (15.2) |

| Maximum Skew Within Paira ps/m (ps/ft) | 15.0 (4.6) |

| Dielectric Withstanding Voltage (Vrms) Conductor-to-Conductor Conductor-to-Shield |

1500 1000 |

a Shielded twisted pairs only.

Mechanical and Environmental

| Mechanical / Environmental Property | Value |

|---|---|

| Jacket Material | Engineered Fluoropolymer |

| Jacket Color | White (Laser Markable) |

| Conductor | Silver-Plated Copper Alloy |

| Conductor Color Coding | High-Speed Pairs: Blue/White, Yellow/White, Orange/White, Violet/White Low-Speed Pairs: Green/White Power: Black/Red |

| Dielectric Material | ePTFE/PTFE |

| Temperature Range (°C) | -65 to +200 |

Part Numbers & Drawings

Download the drawings to view cable characteristics, like diameter, weight, minimum bend radius, and insertion loss.

| Part Number | AWG Size (Stranding) |

|---|---|

| 2.0 Version | |

| RCN8800-22D-22P-H | Data Pair: 22 (19/34) Power Pair: 22 (19/34) |

| RCN8800-24D-22P-H | Data Pair: 24 (19/36) Power Pair: 22 (19/34) |

| RCN8800-26D-24P-H | Data Pair: 26 (19/38) Power Pair: 24 (19/36) |

| 3.1 Version | |

| GSC-03-84761-24D | Data Pair: 26 (19/38) Power Pair: 24 (19/36) |

Qualifications

GORE USB Cables have undergone substantial qualification testing to ensure they meet the most current industry standards and our customers’ requirements.

- ABD0031 (AITM 3.0005); BSS7239: Toxicity

- ABD0031 (AITM 3.0008B); BSS7238; FAR Part 25, Appendix F, Part V: Smoke Density

- ANSI/NEMA WC 27500: Environmental Testing, Jacket and Marking

- CS/FAR Part 25, Section 25.853, Appendix F, Part I (b)(7): Flammability

- SAE AS4373™: Test Methods for Insulated Electric Wire (Contact Gore for available data)

Fill out a short form to receive a complimentary sample of our pre-qualified cables for prototyping and evaluation from our authorized global distributors, Air Cost Control (Europe) or WireMasters (US).

Resources

Catalog: GORE® High Speed Data Cables for Aerospace & Defense

Brochures, Data Sheets,

Recent News

Stop by Booth 1218 to see our demos and learn how GORE® Cables and Materials perform reliably despite Army airframe and aviation challenges. We’re eager to hear about your latest systems and collaborate with you to deliver solutions that ensure mission success and protect our aircrew.

Press Release

W. L. GORE & ASSOCIATES TO PRESENT NEW MOSA PAPER AT GVSETS CONFERENCE

Posted August 11, 2023

W. L. Gore & Associates (Gore) will present a new Modular Open Systems Approach (MOSA) technical paper at the Ground Vehicle Systems Engineering & Technology Symposium & Modernization Update (GVSETS) on Tuesday, August 15, in Novi, Mich.

Visit our Booth 2C-C358 to see GORE® Cables and Materials that have been proven and trusted over time in fighter jets, rotorcraft and passenger airliners. Reserve your time slot now for a 1-on-1 discussion to talk with us about your latest airframe and aviation system developments.

Press Release

W. L. Gore & Associates Expands High-Speed Data Transmission Capabilities

Posted April 18, 2023

W. L. Gore & Associates (Gore) announced today its new Cat8 ethernet cable for use in aerospace and defense platforms. The new Cat8 ethernet cable allows for four times the high-speed data transmission previously possible.

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Contact Us

Related Products

Cables & Cable Assemblies

- Ethernet Cables for Civil Aircraft

- Shielded Twisted Pair Cables for Civil Aircraft

- CAN Bus Cables for Civil Aircraft

- Quad Cables for Civil Aircraft

- FireWire® Cables for Civil Aircraft

- Fibre Channel Cables for Civil Aircraft

- HDMI Cables for Civil Aircraft

- DVI Cables (Digital Only) for Civil Aircraft

- Fiber Optic Cables for Civil Aircraft

- Cable Protection Systems for Civil Aircraft

- Abrasion Resistant Cable Jacket for Civil Aircraft

Follow GORE® USB Cables for Civil Aircraft