GORE® Ozonation Modules for Semiconductor & Microelectronics Processing

With a proven track record of over 40 years, Gore's modules have generated the cleanest, bubble-free, highest concentration ozone water for cleaning silicon wafers and semiconductor and FPD fabrication processing. They support an environmentally friendly cleaning process to reduce harsh chemicals, improve process performance and reduce operating costs.

Contact Us

United States

+1 800 356 4622

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Overview

SHIFT TOWARD OZONE WATER TREATMENT TO REDUCE CHEMICAL CONSUMPTION

The industry traditionally uses chemical-based mixtures for SI cleaning and semiconductor cleaning applications. But, they’re moving towards an ozone functional water treatment that is friendlier to the environment, reduces waste and costs less.

Manufacturers want a safe, energy-efficient organic removal and surface treatment using cleaning liquid at room temperature. They also want to reduce traditional chemical consumption that isn’t environmentally friendly and costs more for waste treatment. An example is the SPM process that uses a mixture of hydrogen peroxide and hot sulfuric acid — a corrosive and harmful chemical that increases waste treatment costs.

They also need cleaner ozonated water at a higher ozone dissolution concentration beyond the current benchmark to help increase yield. Clean ozonized water ensures organic wafer contamination is removed on silicon (Si) wafers and flat panel displays (FPD).

HOW GORE’S MODULES HELP IMPROVE SEMICONDUCTOR CLEANING PROCESSES

Since the 1980s, GORE Ozonation Modules have been successfully used in an ozone water-based wafer cleaning tool for silicon wafer and semiconductor applications. This ozonation module provides a safer and more effective treatment using deionized ozone water (DI-O3 water) than commonly used methods involving harsh chemicals and many semiconductor cleaning process steps.

For instance, wet cleaning and photoresist removal methods use chemicals in the preparation of silicon wafer cleaning, followed by an SPM wet cleaning process that also uses chemicals to remove the remaining organic contaminants.

CLEANEST, BUBBLE-FREE OZONE WATER SOLUTION

Proven, Continuous, Consistent Concentration & Flow

Gore’s modules generate the cleanest, bubble-free, ozonized ultra-pure water on the market today — cleaner than ozone water generated by mechanical mixer technology, like an ejector or static mixer.

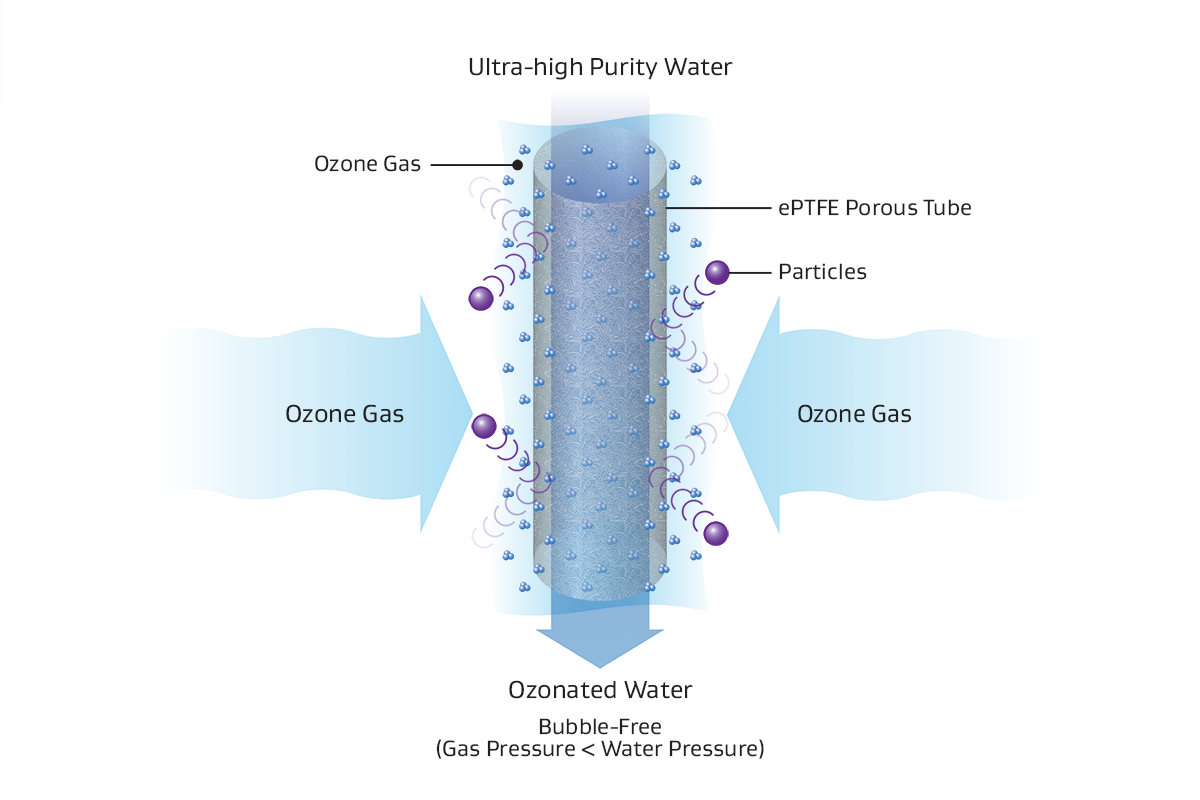

These modules can also achieve the highest dissolved ozone concentrations up to 200 mg/L. They continuously and consistently dissolve ozone gas into ultra-high pure water to generate the cleanest, bubble-free ozone water. We manufacture our ozone modules with microporous fluoropolymer membranes that allow high water entry pressure (WEP) of more than 0.40 MPa.

With this level of proven continuous, consistent concentration and flow, GORE Ozonation Modules are the ideal solution in ozone water systems for clean SI wafer and FPD applications.

The dissolving ozone-in-water mechanism is diffusion based on the difference in total gas pressure, which generates the cleanest bubble-free ozone water.

ADVANTAGES OF GORE OZONATION MODULES COMPARED TO MECHANICAL MIXERS

Compare GORE Ozonation Modules against mechanical mixers to better understand the advantages of our product. For more information about the characteristics and performance of our modules, contact us today.

| Critical Attributes | GORE Ozonation Modules | Mechanical Mixers (injector/ejector & static mixer) |

|---|---|---|

| Cleanliness |

|

|

| Operability |

|

|

Applications

GORE Ozonation Modules are a cost-effective solution for use in leading-edge SEMI process ozone water applications and cleaning processes with ozone in the microelectronics industry, like:

- Silicon wafer cleaning and production

- Logic and memory fabrication

- LED/OLED/QOLED (LTPS) flat panel display cleaning & production

- Photomask

If you have any questions or to discuss your specific application needs, contact us today.

Features & Benefits

GORE Ozonation Modules provide numerous features and benefits for semiconductor cleaning equipment manufacturers that improve ozone water cleaning processes such as:

- Bubble-free, ultra-high purity ozone water at highest concentration up to 200 mg/L

- Cleanest ozone water due to unique fluoropolymer construction

- No particle contamination due to ePTFE membrane tube

- High WEP > 0.40 MPa due to microporous membrane technology

- Proven continuous and consistent operation

- Easy-to-control ozone water flow rate and concentration

For more information about the features and benefits of our ozonation modules, contact us today.

Characteristics

These values demonstrate the characteristics of GORE Ozonation Modules for semiconductor and microelectronics processing.

| Property | Gore Part Number | |

|---|---|---|

| GN-142-300 | GN-142-650 | |

| Length (Flange-to-Flange) mm | 300 | 650 |

| Diameter mm | 142 | 142 |

| Membrane Material | Expanded PTFE | Expanded PTFE |

| Housing Material | PTFE/PFA | PTFE/PFA |

| Ozone Concentration ppm | Up to 200 | Up to 200 |

| Water Entry Pressure (WEP) MPa | > 0.40 | > 0.40 |

| Maximum Liquid Pressure MPaG | 0 to 0.35 | 0 to 0.35 |

| Maximum Gas Pressure MPaG | 0.25 | 0.25 |

| Recommended Operating Temperature °C | 0 to +30 | 0 to +30 |

How to Buy

LEARN MORE ABOUT GORE OZONATION MODULES OR ORDER NOW

Using a unique microfiltration membrane technology, Gore’s modules generate the highest purity and bubble-free ozone water in the industry today. They’re proven to be a reliable solution for improved semiconductor wafer cleaning and FPD fabrication processing that are friendlier to the environment. For more technical information and to order our ozonation modules, contact us today.

Resources

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Follow GORE® Ozonation Modules for Semiconductor & Microelectronics Processing