GORE® Insulated Wires for Oil and Gas Downhole Equipment

Cables and wires are vital components in downhole equipment, and the consequences can be costly if they fail. Whether you need wires for power, signal, magnet or thermocouple, GORE Insulated Wires deliver failure-free performance and protection in a smaller, more durable package extending equipment life in harsh environments.

Contact Us

United States

+1 800 356 4622

Germany

+49 9144 6010

+49 9144 6816 (fax)

UK

+44 1382 56 1511

+44 1382 56 1007 (fax)

Italy

+39 045 6209 209

+39 045 6209 165 (fax)

France

+33 1 5695 6565

+33 1 5695 6401 (fax)

Spain

+34 93 480 6900

+34 93 373 7850 (fax)

Sweden

+46 31 7067800

+46 31 864226 (fax)

China (Beijing)

+86 10 5707 4999

+86 10 5707 4900 (fax)

China (Shanghai)

+86 21 5172 8299

+86 21 6247 9199 (fax)

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Japan

+81 3 6746 2582

+81 3 6746 2571 (fax)

Overview

Cables and wires in downhole equipment are often exposed to severe conditions that can easily compromise their performance — from vibration and abrasion to high temperatures, aggressive chemicals, and harsh fluids. So, they need to be much stronger, perform reliably and last longer to survive deep drilling. At the same time, cables and wires need to be smaller and more flexible to fit inside cramped spaces of smaller tools.

Constructed with uniquely engineered fluoropolymers, GORE Insulated Wires are designed specifically to withstand extreme oil and gas downhole environments. They provide superior mechanical protection against harsh chemicals and hydrolysis in high temperatures typically found in downhole environments. They also withstand repeated mechanical stress such as vibration and abrasion caused by deep drilling. These high-strength insulated wires also deliver outstanding electrical performance with dependable signal integrity for high-speed data transmission over longer distances, eliminating the need for additional signal amplification.

Unsurpassed Performance in Harsh Conditions

GORE Insulated Wires withstand continuous exposure to hazardous environmental contaminants such as acid, water, steam, synthetic oil, methane, and hydrogen sulfide at extreme temperatures while delivering consistent power and critical real-time data to operators. That’s because our unique thin-wall insulation improves signal integrity and provides higher signal density, which means smaller, more durable solutions in your application.

We compared our insulated wires to standard PTFE-PI-PTFE insulated wires using test method ASTM D2307. Results showed that GORE Insulated Wires provided enhanced tensile strength up to 39,530 psi (272 MPa). Ultimately, our wires are much stronger and more flexible so that they won’t break as easily during winding and handling operations, like the other insulated wires. Also, our wires performed reliability in wide temperatures, achieving a thermal class rating of 300° C (572° F).

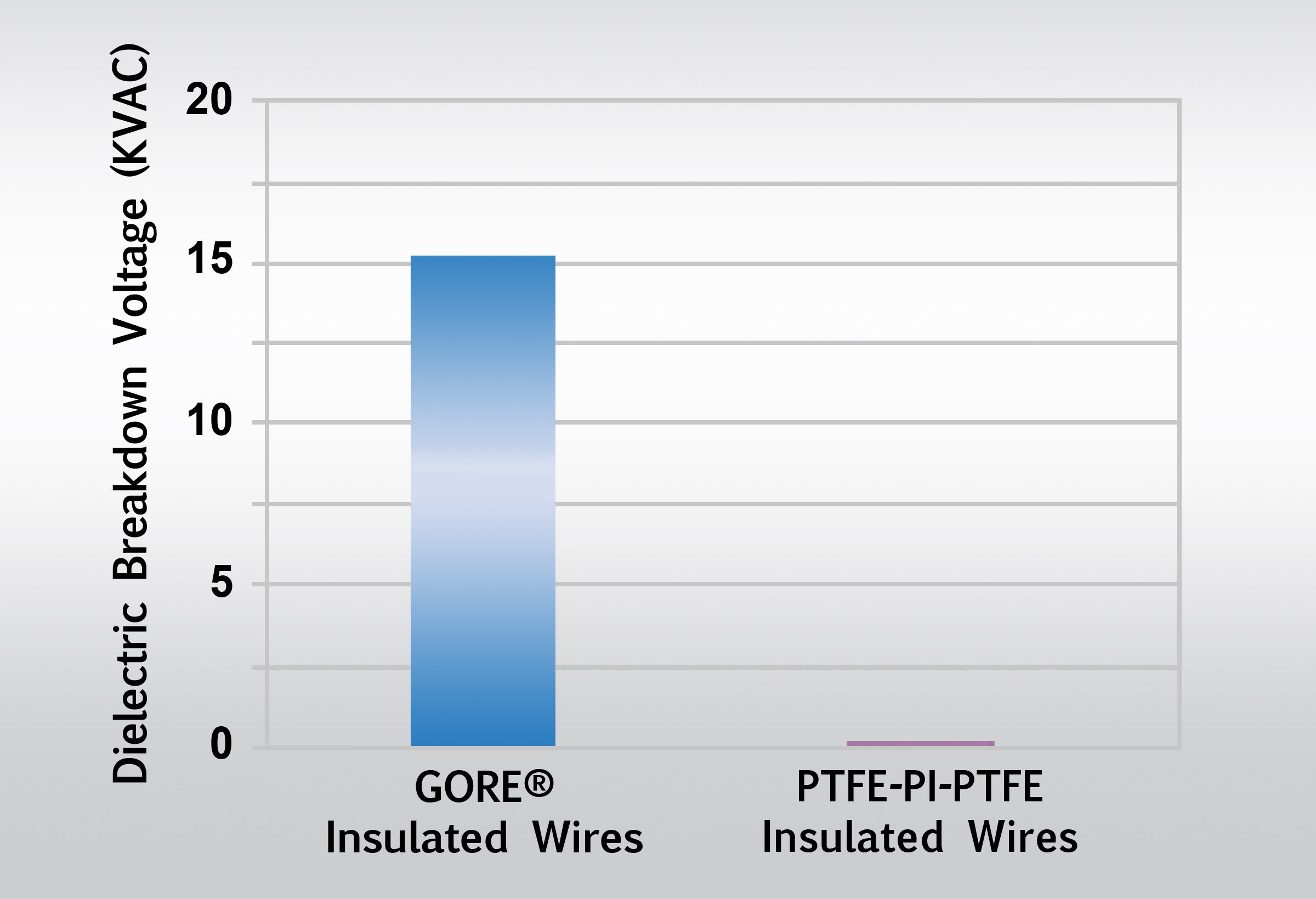

Comparison of dielectric breakdown voltage after 1500 hours exposure to hydrolysis @ 98° C (208° F)

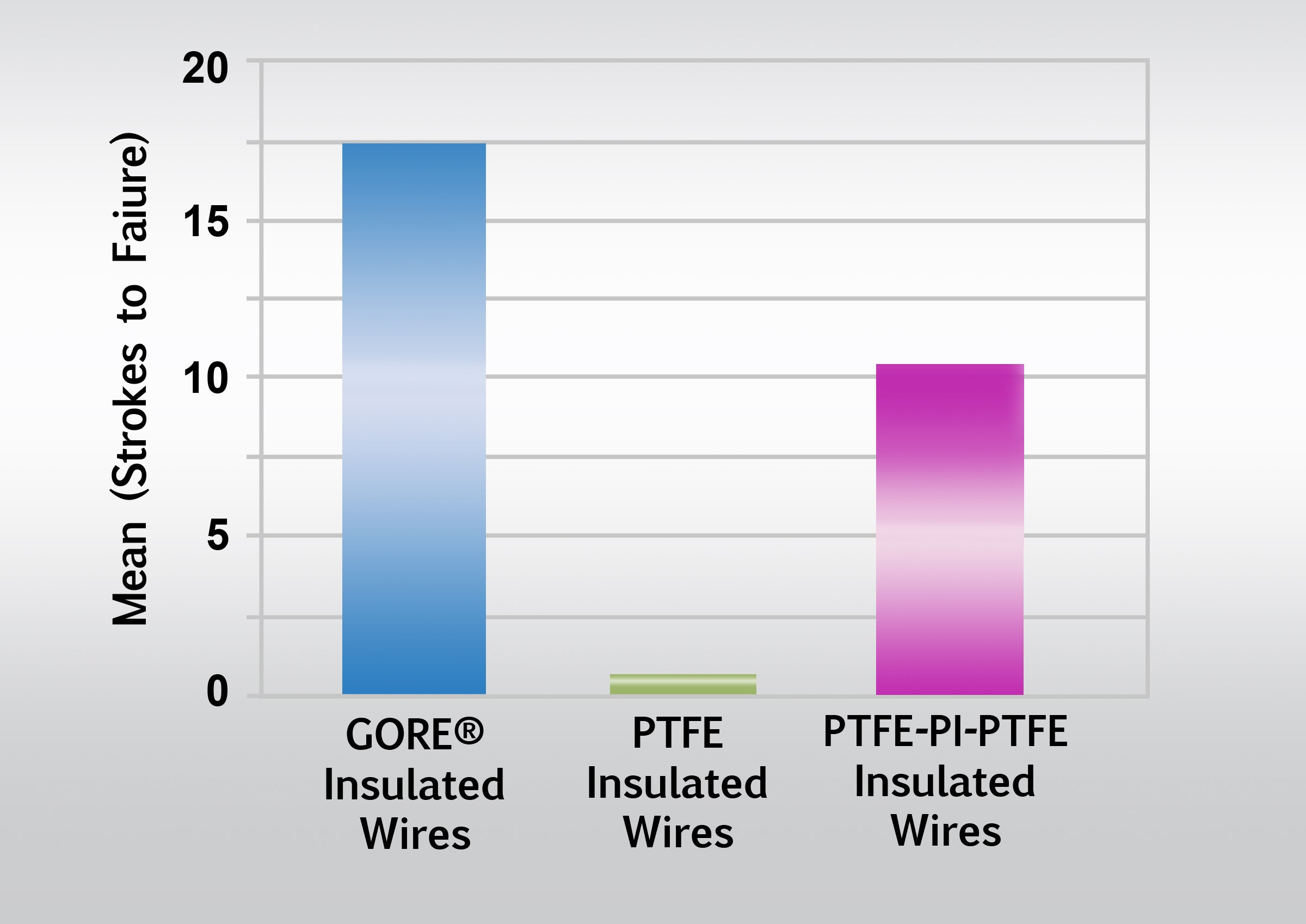

Outstanding Abrasion Resistance

Results also showed that GORE Insulated Wires are more resistant to scrape abrasion compared to conventional PTFE and PTFE-PI-PTFE wire insulation. Our wires not only maintain the excellent chemical resistance of PTFE but also improve mechanical strength and performance for extended product life in any downhole application.

You no longer have to accept frequent wire failure and costly cable repairs in the field. GORE Insulated Wires are a proven solution for reducing downhole tool failures by delivering long-lasting protection and performance.

Gore internal Windability Test: 36lbs normal force, 30in/min, 10 strockes without any visible tearing of the insulation material

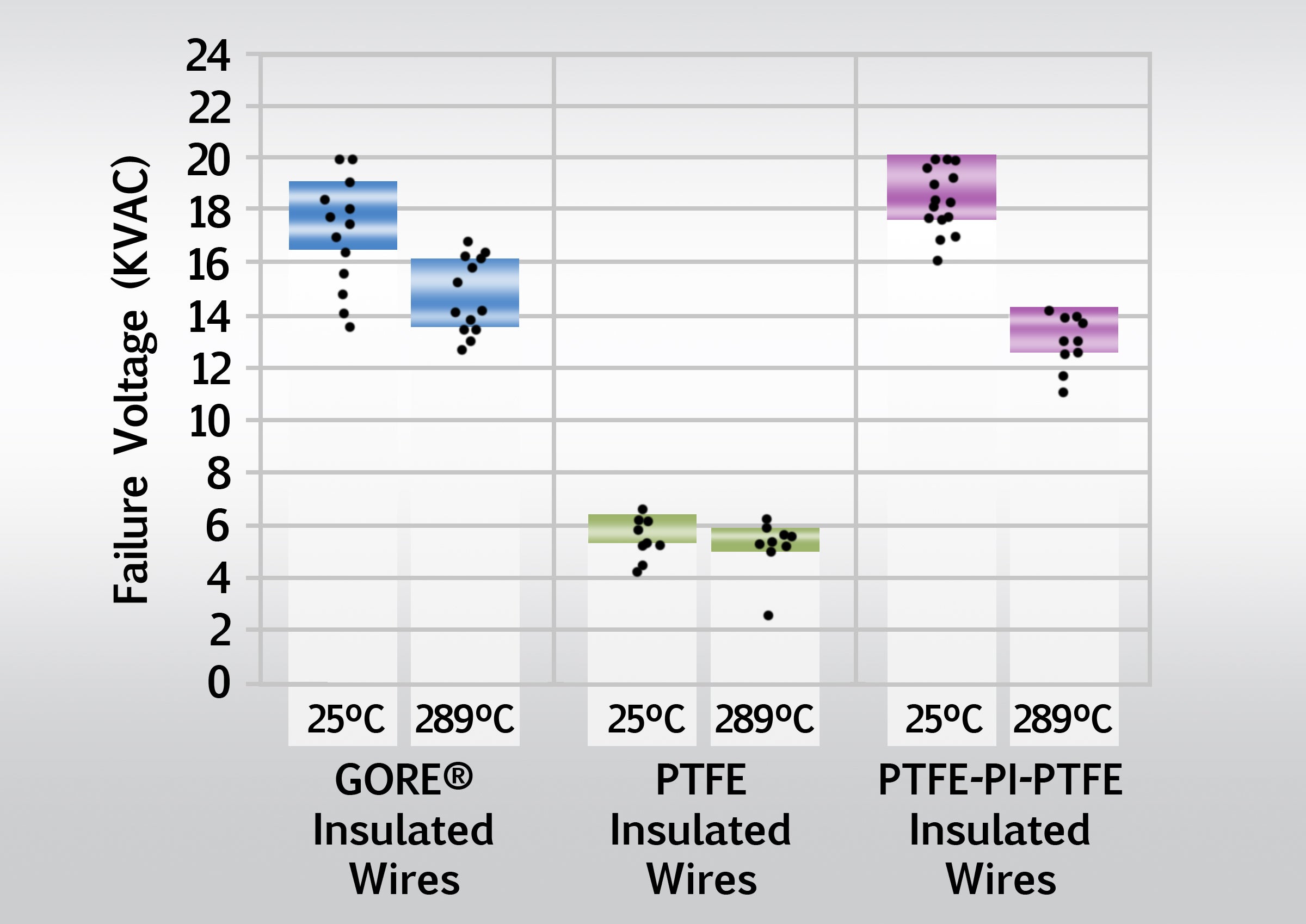

Comparison of dielectric breakdown at room temperature and high temperature

Scrape abrasion comparison of insulated wires

Applications

Typical applications for GORE Insulated Wires are in any down hole environment where the existence of water, temperature or chemicals can cause a negative impact to the life and or performance of the electronics, Downhole motors/windings:

- Generators

- Electric Motors

- Solenoids

- Transformers

Or as in non-winding applications like high-temperature cable systems:

- EPS or downhole pre-heating power cables

- Sensor cables

- High-temperature hook-up wires

- Thermocouple wires

If you have any questions or to discuss your specific application needs, please contact a Gore representative.

Benefits

GORE Insulated Wires provide manufacturers with many benefits that improve electrical and mechanical performance such as:

- high-speed data transmission over longer distances eliminating the need for additional signal amplification

- increased power density at high temperatures due to high-strength wire insulation

- exceptional resistance to chemicals and hydrolysis in extreme environments with temperatures up to 300° C

- enhanced tensile strength for less wire breakage

- longer tool life with abrasion-resistant wire insulation

- increased design options with smaller diameters and more durable construction

- simple routing in confined spaces due to smaller wires with greater flexibility

For more information about the benefits of our cables, please contact a Gore representative.

Properties

Gore's tests were modified to achieve better accuracy in comparing GORE Insulated Wires to conventional PTFE and PTFE-PI-PTFE wire insulation. Results are based on bare copper wires insulated with 6-millimeter wall insulation material. Results for tensile strength and dielectric constant are based on film material.

For more information about the benefits of our cables, please contact a Gore representative.

| Test Method | GORE® Insulated Wires |

Conventional PTFE Insulated Wires |

PTFE-PI-PTFE Insulated Wires |

|

|---|---|---|---|---|

| Tensile Strength (psi/MPa) | Gore test based on ASTM D88312 | 39,530 psi 272.55 MPa |

2,253psi 15.5 MPa |

17,589 psi 121.27 MPa |

| Dielectric Constant @ 23°C (73°F) | ASTMD150 | 2.1 | 2.1 | 2.85 |

| Dielectric Breakdown Voltage @ 23°C (73°F) | Gore test based on NEMA MW 1000,3.8.2 | 17 kVAC | 5.8 kVAC | 18.2 kVAC |

| Dielectric Breakdown Voltage @ 289°C (552°F) | Gore test based on NEMA MW 1000,3.8.2 | 14.5 kVAC | 4.9 kVAC | 13.2 kVAC |

| Dielectric Breakdown Voltage after 1500 hrs exposure to Hydrolysis @ 98°C (208°F) | Gore test based on NEMA MW 1000,3.8.2 | 15.4 kVAC | Not Tested | 0 kVAC |

| Scrape Abrasion | Gore test based on ASTM D1676, Sec.17 | 17.6 cycles | 0.7 cycles | 10.4 cycles |

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Contact Us

Related Products

Cables & Cable Assemblies