GORE® High Flex Cables & Assemblies: Cleanliness Grades 2 and 4

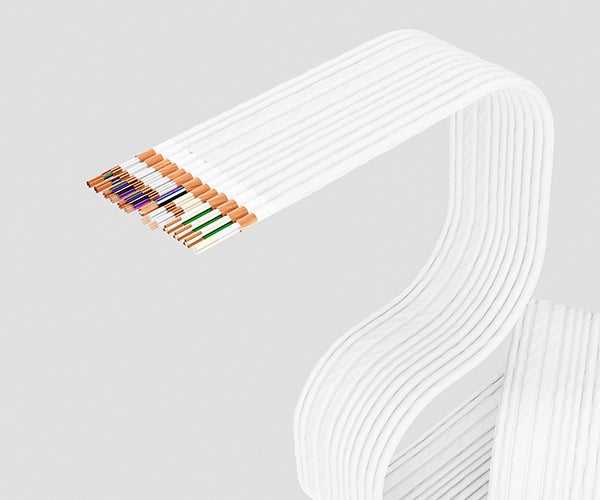

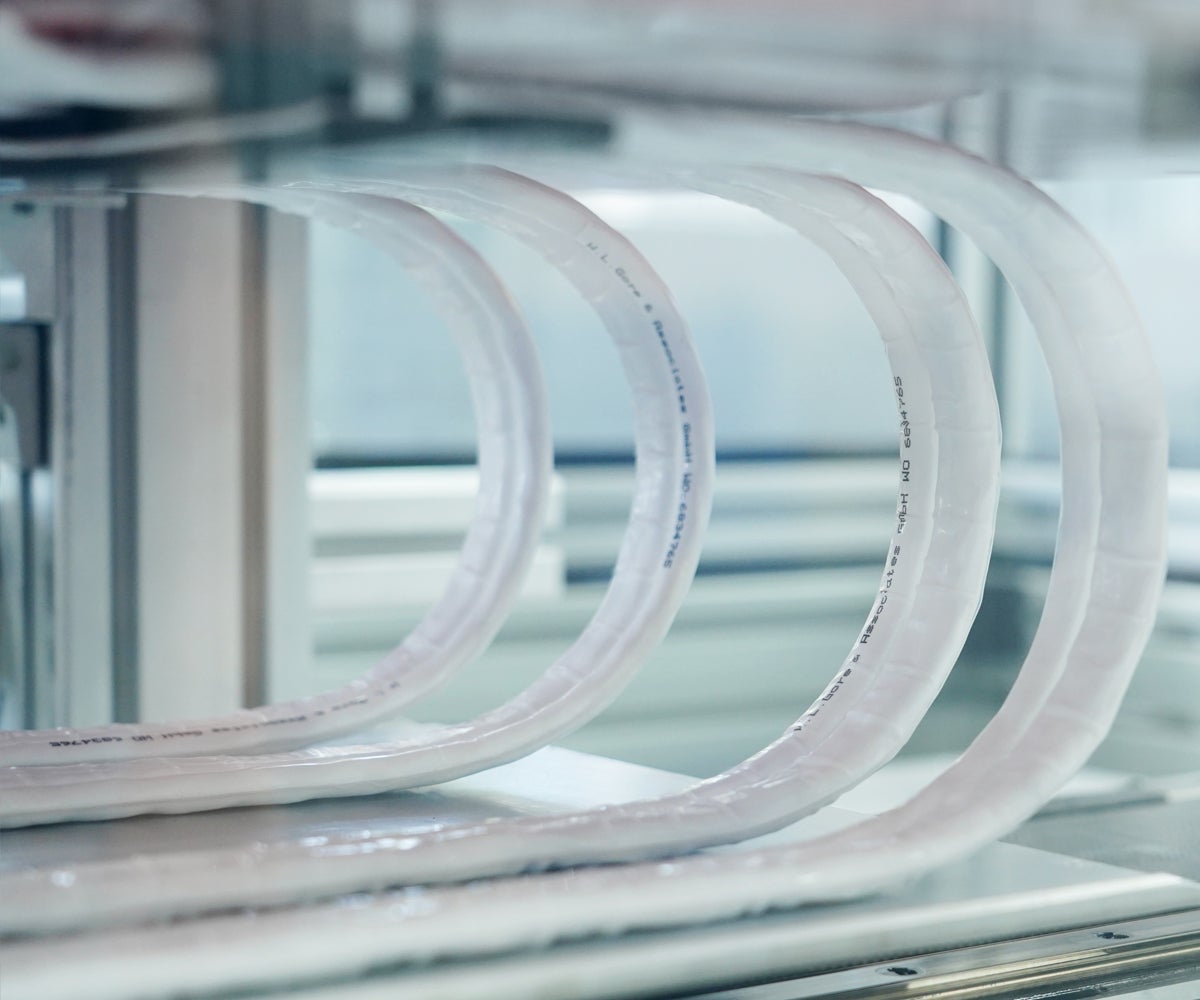

These low-contamination, low-particulation high-flex cables for vacuum and non-vacuum applications perform reliably over multi-million flex cycles, even at higher speeds and acceleration, for less maintenance and more EUV and DUV machine uptime.

Contact Us

United States

+1 800 356 4622

Europe

+49 9144 6010

China

+86 755 8359 8262

South Korea

+82 2 393 3411

Industry Overview

The Lithography Industry: Development and Challenges

The growing demand for semiconductors — driven by 5G, the Cloud and AI — will only intensify as ever-more devices and technologies are integrated into homes, workplaces and transportation systems. To meet this accelerating demand, fabs using EUV and DUV lithography processes must increase their speeds and output — without sacrificing purity or precision in the process.

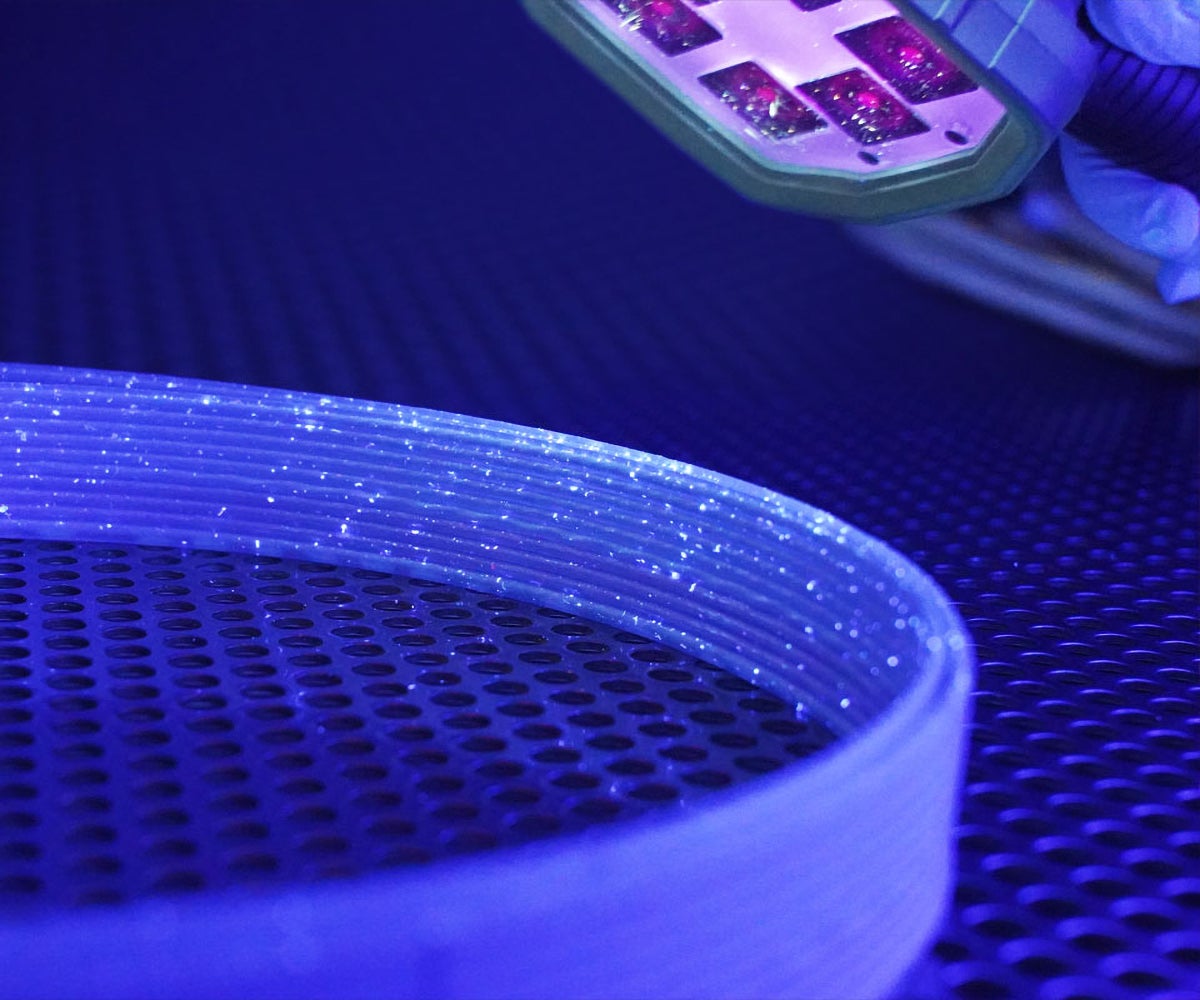

GORE High Flex Cables & Assemblies are custom-configured and engineered to meet EUV and DUV needs for lowest particulation — even after continuous flexing > 20 million times. And Gore’s vacuum-compatible cables are always RGA (Residual Gas Analysis) tested, to ensure cleanliness that meets customer specifications.

|

» Learn more about the heightened challenges facing the industry. |

Product Benefits

GORE® High Flex Cables & Assemblies: Unmatched Qualification

Designed for flexible applications, these finished cables and assemblies provide the unmatched cleanliness an EUV high-vacuum environment demands, along with the extreme durability, flexibility and reliability that both EUV and non-vacuum DUV systems need to meet industry demands for higher yields and productivity. Each High Flex cable solution is custom-designed and co-engineered to your specifications. And we customize without compromise, because we:

- Incorporate and customize raw materials to provide the low outgassing, low particulation and low contamination that advancing EUV technologies require.

- Employ IP-protected cleaning processes that meet specifications for both EUV Cleanliness Grade 2 cables and DUV Cleanliness Grade 4 cables.

- Deliver cables and assemblies with a proven flex life and reliability to withstand repeated multi-million flex cycles.

- Enable higher data-rate cables with increased transmission speeds, and high and uncompromising signal integrity.

Technical Specifications

| Property | Vacuum (acc. to Cleanliness Grade 2) |

Non-vacuum (acc. to Cleanliness Grade 4) |

|---|---|---|

| Jacket material | PTFE | expanded PTFE (ePTFE) composite |

| Jacket color | white | white |

| Core types | signal, power, pneumatic, fluids | signal, power, fiber optic, pneumatic, fluids |

| Maximum self-supporting length [mm (inch)] |

500 (20) | 500 (20) |

| Maximum width of cable [mm (inch)] |

130 (5) | 300 (12) |

| Minimum bend radius | >10 x OD a) | >10 x OD a) |

| Maximum acceleration [m/sec2] b) | >40 a) | >40 a) |

| Speed [m/sec] | >3 a) | >3 a) |

| Flex life (Cycles) (BR. 50 mm up to 4G accelerations) |

> 20 million a) | > 20 million a) |

| Temperature range [°C] | -20 to +260 a) | -20 to +90 a) |

| Particulation c) (ISO14644-1 / VDI Guideline 2083) |

< 0.1 % | < 0.1 % |

| Outgassing rate [mBar x l/sec x cm2] |

||

| H20 (AMU 18) d) |

4.00E-09 | n.a. |

| CxHyv (volatile CxHy) (AMU 45-100) d) |

1.00E-10 | n.a. |

| CxHynv (non-volatile CxHy) (AMU 101-200) d) |

6.00E-12 | n.a. |

| Particle-free | applicable | applicable |

| Certifications | UL | UL |

a) depending on application requirements

b) For applications requiring higher acceleration and speed, please contact a Gore representative.

c) Details of the Fraunhofer Institute's study available at gore.com/particulation.

d) AMU = Atomic Mass Units

Lithography Applications

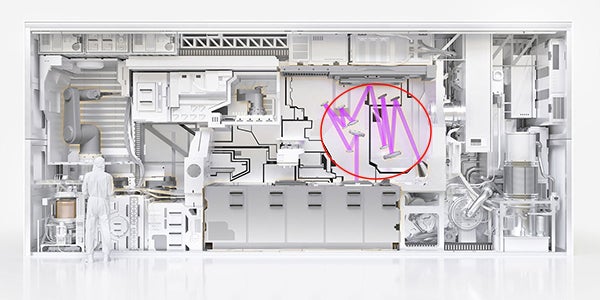

EUV Machines

Within EUV systems, Gore’s high flex cables for lithography deliver the proven cleanliness and durability needed for multiple applications:

- Wafer handler

- Wafer stage

- Reticle handler

- Reticle stage and reticle mask

- And many more…

Metrology Machines

The tested and proven quality of GORE® High Flex Cables & Assemblies supports the productivity and precision of automated inspection systems:

- Optical metrology systems

- Mask inspection systems

- eScan multiple e-beam systems

|

» Learn more about how Gore tests its cables & assemblies for purity, quality and correctness. |

Have a new application with challenging cabling specs? Let’s talk about what Gore can do to meet them!

The Gore Advantage

When it comes to Lithography, you need more than just cable and assembly “products” — you need leading-edge, integrated cable and assembly solutions that are backed by a resourceful, capable and proven partner.

Why Choose Gore and Gore Cable Solutions for Lithography?

Working with Gore, and specifying reliable Gore cables and assemblies for static and high-flex EUV and DUV applications, can help you reduce maintenance and downtime, even when running at higher wafer/hour speeds over multi-million production cycles. We’re not just here to provide ultra-high vacuum cables — we’re here to meet ultra-high expectations as well.

| Built-In Cleanliness and Reliability | A Partner Dedicated to Quality |

|---|---|

| Lowest contamination from CxHy and H20 | Years of experience |

| Low friction materials for lowest particulation | Co-engineering and material expertise |

| Reliable signal integrity for high-speed data transmission over longer distances | Unmatched cleanliness throughout the entire process |

| Tight routing for easy installation in tight spaces | Extensive lab testing that ensures the highest quality |

Resources

News & Events

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Contact Us

Related Industries

Related Products

Cables & Cable Assemblies

Follow GORE® High Flex Cables & Assemblies: Cleanliness Grades 2 and 4