Materials Science Innovation

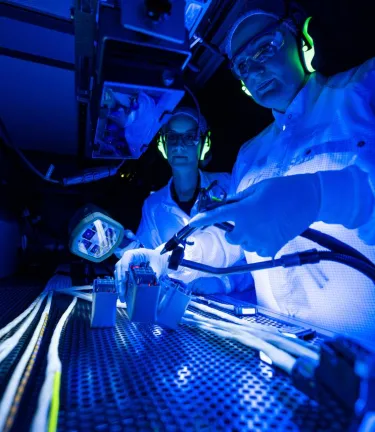

At the heart of innovation at Gore is our distinct culture and passion for solving our customers’ most complex challenges using by applying our materials science expertise and technical capabilities.

At Gore, our curiosity, creativity and collaboration ignite the development of advanced materials and new technologies that improve lives and industries. We innovate with purpose to solve some of our customers’ — and the world’s — greatest challenges.

With more than 3,100 unique inventions, our products enhance everyday experiences, mend hearts, explore space and stand up to the most demanding environments.

Our materials science expertise drives innovation across the broad portfolio of our Fabrics, Medical, Performance Solutions and Specialty businesses.

Advanced Materials

From our earliest days as a wire and cable company supporting the budding computer industry, we have always focused on contributing value to society by solving our customers' most challenging problems. This commitment is alive today in our products that safeguard our environment, protect first responders, improve patient outcomes and solve other complex challenges.

Over the past 65 years, we have developed unparalleled expertise in processing and expanding polymers to bring value to customers, end users and the world. Examples range from garments with a lower environmental footprint and innovative bioabsorbable medical devices to advanced mercury filtration systems and silicone-free plungers for sensitive biologic medicines.

We continue to explore and deliver new composites both internally and in collaboration with others. Introducing novel materials and processing capabilities spurs product innovation and commercial success for Gore’s existing businesses and new ventures.

Product Performance Begins with Materials

To provide the performance qualities required by the application and valued by the customer, we can optimize material attributes through:

- Proprietary formulations

- Varied structures, such as high or low density, tight or open pores, thinness or thickness, surface or cross-section orientation, and multiple geometries and asymmetries

- Multiple forms, including tapes, membranes, films, tubes, fibers, sheets and rods

- Various proprietary modifications that allow us to produce highly valuable end products

Learn more about the solutions we deliver and the industries we serve.